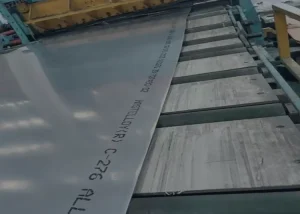

ASTM A588

- Home

- Products

- Carbon Steel Stocks

- ASTM A588

Basic Info

The ASTM A588 standard specifies the standard specifications for weather resistant steel plates and profiles used in bridges, buildings, and other structures.

Characteristics

Corrosion Resistance: ASTM A588 steel is renowned for its exceptional corrosion resistance, particularly in atmospheric environments. It forms a protective oxide layer on its surface, which inhibits further corrosion and enhances durability, making it suitable for outdoor applications.

High Strength: ASTM A588 steel exhibits high strength properties, allowing it to withstand heavy loads and structural stresses. This makes it ideal for use in bridges, buildings, and other load-bearing structures where strength is essential.

Low Alloy Composition: ASTM A588 is a low-alloy structural steel, containing small amounts of alloying elements such as copper, chromium, and nickel. These elements contribute to the steel’s corrosion resistance and mechanical properties without significantly increasing its cost.

Toughness: ASTM A588 steel exhibits good toughness properties, enabling it to withstand impact and deformation under high stress conditions. This ensures structural integrity and reliability in demanding environments.

ASTM A588 Data Sheet

Chemical Composition:

- ASTM A588 Steel: Contains higher levels of copper, chromium, and nickel for improved corrosion resistance.

- ASTM A572 Steel: Contains higher levels of carbon, manganese, and other alloying elements for increased strength and hardness.

Corrosion Resistance:

- ASTM A588 Steel: Offers superior atmospheric corrosion resistance, making it ideal for outdoor applications.

- ASTM A572 Steel: Generally lower corrosion resistance compared to ASTM A588, suitable for indoor or protected environments.

Strength and Toughness:

- ASTM A588 Steel: Moderate to high strength with good toughness, suitable for structural applications in challenging environments.

- ASTM A572 Steel: Higher strength and hardness compared to ASTM A588, suitable for heavy-duty structural applications.

Weldability:

- ASTM A588 Steel: Weldable using standard welding processes with proper precautions for preheating and post-weld heat treatment.

- ASTM A572 Steel: Weldable using common welding techniques, although preheating and post-weld heat treatment may be required for thicker sections.

Applications:

- ASTM A588 Steel: Commonly used in outdoor structures such as bridges, buildings, and transmission towers where corrosion resistance is essential.

- ASTM A572 Steel: Widely used in structural applications such as bridges, buildings, and machinery requiring high strength and durability.

ASTM A588 Grade A:

- High-strength, low-alloy structural steel with improved atmospheric corrosion resistance. Suitable for outdoor applications such as bridges, buildings, and structural components.

- Corrosion Resistance: Moderate.

ASTM A588 Grade B:

- High-strength, low-alloy structural steel with improved atmospheric corrosion resistance. Similar to Grade A but with slightly higher corrosion resistance. Used in outdoor environments where higher corrosion resistance is required.

- Corrosion Resistance: Moderate to High.

ASTM A588 Grade K:

- High-strength, low-alloy structural steel with improved atmospheric corrosion resistance. Designed for applications requiring superior corrosion resistance, especially in marine environments or harsh atmospheric conditions.

- Corrosion Resistance: High.

Shape:

Plates, sheets, bars, beams, channels, angles, and structural sections.

Width:

Up to 120 inches (3048 mm) for plates and sheets; various widths for other shapes.

Thickness:

1/4 inch (6.35 mm) to 4 inches (101.6 mm) for plates and sheets; various thicknesses for other shapes.

Length:

Up to 480 inches (12,192 mm) for plates and sheets; various lengths for other shapes.

Tolerance Width:

Standard mill tolerances apply.

Tolerance Length:

Standard mill tolerances apply.

Tolerance Thickness:

Standard mill tolerances apply.

Flatness:

As specified in ASTM A6/A6M.

Surface Finish:

As specified in ASTM A6/A6M.

United States:

- Equivalent Grade: ASTM A588 Grade A/B/K

- Standard: ASTM A588

- Notes: Commonly used in the US for structural applications with improved atmospheric corrosion resistance.

European Union:

- Equivalent Grade: S355J0W, S355J2W

- Standard: EN 10025-5

- Notes: European standard equivalent for structural steel with improved atmospheric corrosion resistance.

China:

- Equivalent Grade: Q345NH, Q355NH

- Standard: GB/T 4171

- Notes: Chinese standard equivalent for weathering steel with improved atmospheric corrosion resistance.

Japan:

- Equivalent Grade: SMA400AW, SMA490AW

- Standard: JIS G3114

- Notes: Japanese standard equivalent for structural steel with improved atmospheric corrosion resistance.

- Carbon (C): 0.19 – 0.25

- Manganese (Mn): 0.80 – 1.25

- Phosphorus (P): 0.04 max

- Sulfur (S): 0.05 – 0.50

- Silicon (Si): 0.30 – 0.65

- Chromium (Cr): 0.40 – 0.65

- Nickel (Ni): 0.40 max

- Copper (Cu): 0.25 – 0.40

ASTM A588 Grade A:

- Tensile Strength (ksi): 70-95 (70 min)

- Yield Strength (ksi) (min): 50 min

- Elongation in 8″ (%) (min): 18%

- Elongation in 2″ (%) (min): 21%

- Charpy V-Notch Impact Test (ft-lbs): 20 min at -20°C (-4°F)

ASTM A588 Grade B:

- Tensile Strength (ksi): 70-95 (70 min)

- Yield Strength (ksi) (min): 50 min

- Elongation in 8″ (%) (min): 18%

- Elongation in 2″ (%) (min): 21%

- Charpy V-Notch Impact Test (ft-lbs): 20 min at -20°C (-4°F)

ASTM A588 Grade K:

- Tensile Strength (ksi): 70-100 (70-100 range)

- Yield Strength (ksi) (min): 50 min

- Elongation in 8″ (%) (min): 18%

- Elongation in 2″ (%) (min): 21%

- Charpy V-Notch Impact Test (ft-lbs): 20 min at -20°C (-4°F)

Fabrication:

Cutting

- Guidelines: Use mechanical cutting methods such as sawing, shearing, or flame cutting. Avoid excessive heat input to prevent degradation of material properties.

- Notes: Proper preheating may be required for thick sections to minimize internal stresses and distortion.

Forming

- Guidelines: Perform cold forming operations such as bending and rolling. Use a press brake or similar equipment to ensure uniform deformation and avoid excessive strain hardening.

- Notes: Avoid hot forming operations that can lead to reduced toughness and increased susceptibility to cracking.

Machining

- Guidelines: Use conventional machining techniques such as milling, drilling, and turning. Employ sharp tools and adequate coolant to minimize work hardening and tool wear.

- Notes: Preheat workpiece if necessary to reduce machining forces and extend tool life.

Welding:

Welding Processes

- Guidelines: Suitable processes include shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW).

- Notes: Choose welding process based on material thickness, joint configuration, and desired mechanical properties.

Preheating

- Guidelines: Preheat base metal and maintain interpass temperature within specified range to reduce the risk of hydrogen-induced cracking. Consult welding procedure specifications (WPS) for recommended preheat temperatures.

- Notes: Preheat temperature and interpass temperature depend on material thickness, carbon equivalent, and welding parameters.

Welding Consumables

- Guidelines: Select welding consumables with matching or slightly higher tensile and yield strengths than base metal. Use low-hydrogen electrodes or wires to minimize hydrogen content in the weld deposit.

- Notes: Ensure proper storage and handling of consumables to prevent moisture absorption and degradation of performance.

Post-Weld Heat Treatment (PWHT)

- Guidelines: Perform PWHT if required to relieve residual stresses and improve toughness. Follow specific PWHT procedures specified in applicable welding codes or standards.

- Notes: PWHT may be necessary for thick sections or when welding highly restrained joints to prevent cracking.