Alloy

Alloy Basic Info

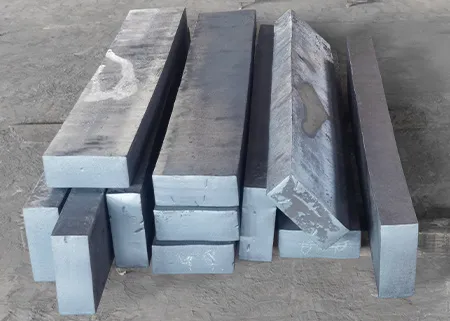

Description

Alloy steel is a type of steel that improves its performance by adding other alloying elements to ordinary carbon steel. These alloying elements typically include chromium, nickel, molybdenum, vanadium, etc. Alloy steel can have various performance characteristics depending on the type and content of its alloying elements, such as high strength, wear resistance, corrosion resistance, etc. Alloy steel is commonly used in the manufacturing of engineering structures, automotive parts, aerospace components, tools, bearings, etc., to meet the requirements for higher material strength, hardness, wear resistance, etc.

Hastelloy

Hastelloy is a highly corrosion-resistant alloy steel, typically containing elements such as nickel, chromium, molybdenum, etc., used in applications requiring strong corrosion resistance and high temperatures, such as chemical, petroleum, nuclear energy, etc.

Inconel

Inconel steel is a high-temperature and corrosion-resistant alloy steel, often containing elements such as nickel, chromium, etc., with excellent oxidation resistance and creep resistance, used in aerospace, chemical, nuclear energy, and other high-temperature, high-pressure fields.

Monel

Monel steel is an alloy steel containing elements such as nickel, copper, etc., with good corrosion resistance and high-temperature performance, commonly used in seawater, chemical, marine engineering, and other fields.

Incoloy

Incoloy steel is a high-temperature and corrosion-resistant alloy steel, typically containing elements such as nickel, chromium, etc., suitable for applications under high-temperature and high-pressure conditions, such as refining, chemical, power, and other industries.

Alloy Data Sheet

Plate:

- Thickness: 1 – 600 millimeters

- Width: 2200 – 2400 millimeters

- Length: 9500, 10000, 11000, Customized millimeters

Bar:

- Diameter: 5 – 1400 millimeters

- Production Method: Rolling, Cold Drawing, Forging

Pipe:

- Diameter: 16 – 508 millimeters

- Wall Thickness: 8 – 130 millimeters

Hastelloy:

- Hastelloy B

- Hastelloy C

- Hastelloy C276

- Hastelloy X

- Hastelloy N

- Hastelloy G

- Hastelloy W

- Hastelloy G30

Inconel:

- Inconel 600

- Inconel 625

- Inconel 718

- Inconel 800

- Inconel 825

- Inconel X-750

Monel:

- Monel 400

- Monel K-500

- Monel R-405

- Monel 401

- Monel 404

Incoloy:

- Incoloy 800

- Incoloy 825

- Incoloy 800H

- Incoloy 800HT

- Incoloy 901

- Incoloy 925

- Incoloy A-286

Hastelloy C276:

- China: GB/T 15007-2017

- USA: ASTM B574

- Japan: JIS NW0276

- Germany: DIN EN 2.4819

Inconel 625:

- China: GB/T 14957-2018

- USA: ASTM B446, ASTM B564

- Japan: JIS NCF 625

- Germany: DIN EN 2.4856

Inconel 718:

- China: GB/T 14977-2018

- USA: ASTM B637, ASTM B670

- Japan: JIS NCF 718

- Germany: DIN EN 2.4668

Inconel 825:

- China: GB/T 14975-2018

- USA: ASTM B425, ASTM B564

- Japan: JIS NCF 825

- Germany: DIN EN 2.4858

Inconel X-750:

- China: GB/T 15001-2018

- USA: ASTM B637

- Japan: JIS NCF X-750

- Germany: DIN EN 2.4669

Monel 400:

- China: GB/T 14976-2018

- USA: ASTM B164

- Japan: JIS NW4400

- Germany: DIN EN 2.4360

Monel K-500:

- China: GB/T 14970-2018

- USA: ASTM B865

- Japan: JIS NW4401

- Germany: DIN EN 2.4375

Incoloy 800:

- China: GB/T 30889-2014

- USA: ASTM B408, ASTM B564

- Japan: JIS NCF 800

- Germany: DIN EN 1.4876

Incoloy 825:

- China: GB/T 30890-2014

- USA: ASTM B425, ASTM B564

- Japan: JIS NCF 825

- Germany: DIN EN 2.4858

Incoloy 800H:

- China: GB/T 30888-2014

- USA: ASTM B408, ASTM B564

- Japan: JIS NCF 800H

- Germany: DIN EN 1.4876, DIN EN 1.4958

Incoloy 925:

- China: GB/T 15004-2018

- USA: ASTM B805

- Japan: JIS NCF 925

- Germany: DIN EN 2.4858

Hastelloy C276:

- Tensile Strength: ≥690 MPa

- Yield Strength: ≥310 MPa

- Elongation: ≥40%

- Hardness: ≤95 HRC

Inconel 625:

- Tensile Strength: ≥827 MPa

- Yield Strength: ≥414 MPa

- Elongation: ≥30%

- Hardness: ≤30 HRC

Inconel 718:

- Tensile Strength: ≥965 MPa

- Yield Strength: ≥550 MPa

- Elongation: ≥30%

- Hardness: ≤36 HRC

Inconel 825:

- Tensile Strength: ≥550 MPa

- Yield Strength: ≥220 MPa

- Elongation: ≥30%

- Hardness: ≤25 HRC

Inconel X-750:

- Tensile Strength: ≥930 MPa

- Yield Strength: ≥827 MPa

- Elongation: ≥30%

- Hardness: ≤41 HRC

Monel 400:

- Tensile Strength: ≥480 MPa

- Yield Strength: ≥170 MPa

- Elongation: ≥35%

- Hardness: ≤85 HRC

Monel K-500:

- Tensile Strength: ≥1100 MPa

- Yield Strength: ≥860 MPa

- Elongation: ≥20%

- Hardness: ≤27 HRC

Incoloy 800:

- Tensile Strength: ≥520 MPa

- Yield Strength: ≥205 MPa

- Elongation: ≥30%

- Hardness: ≤30 HRC

Incoloy 825:

- Tensile Strength: ≥590 MPa

- Yield Strength: ≥250 MPa

- Elongation: ≥30%

- Hardness: ≤30 HRC

Incoloy 800H:

- Tensile Strength: ≥450 MPa

- Yield Strength: ≥170 MPa

- Elongation: ≥30%

- Hardness: ≤20 HRC

Incoloy 925:

- Tensile Strength: ≥1000 MPa

- Yield Strength: ≥690 MPa

- Elongation: ≥25%

- Hardness: ≤35 HRC

Hastelloy C276:

Nickel (Ni): Balance

Chromium (Cr): 15.0–17.0%

Molybdenum (Mo): 14.5–16.5%

Iron (Fe): 4.0–7.0%

Others: ≤1.0%

Inconel 625:

- Nickel (Ni): 58.0%

- Chromium (Cr): 20–23%

- Molybdenum (Mo): 8–10%

- Iron (Fe): 5.0%

- Aluminum (Al): ≤0.4%

- Titanium (Ti): ≤0.4%

- Others: ≤1.0%

Inconel 718:

- Nickel (Ni): 50.0–55.0%

- Chromium (Cr): 17.0–21.0%

- Molybdenum (Mo): 2.8–3.3%

- Iron (Fe): 18.5%

- Aluminum (Al): 0.65–1.15%

- Titanium (Ti): 0.7–1.15%

- Others: ≤1.0%

Inconel 825:

- Nickel (Ni): 38.0–46.0%

- Chromium (Cr): 19.5–23.5%

- Iron (Fe): 22.0%

- Titanium (Ti): 0.6–1.2%

- Copper (Cu): 1.5–3.0%

- Silicon (Si): 0.5%

- Tin (Sn): 0.2%

- Others: ≤1.0%

Inconel X-750:

- Nickel (Ni): 70.0%

- Chromium (Cr): 14.0–17.0%

- Iron (Fe): ≤7.0%

- Aluminum (Al): 2.25–2.75%

- Titanium (Ti): 0.7–1.2%

- Others: ≤1.0%

Monel 400:

- Nickel (Ni): 63.0–70.0%

- Iron (Fe): 2.5%

- Copper (Cu): Balance

- Sulfur (S): ≤0.024%

- Carbon (C): ≤0.3%

Monel K-500:

- Nickel (Ni): 63.0%

- Copper (Cu): 27.0–33.0%

- Sulfur (S): ≤0.01%

- Carbon (C): ≤0.25%

- Manganese (Mn): ≤2.0%

Incoloy 800:

- Nickel (Ni): 30.0–35.0%

- Chromium (Cr): 19–23%

- Iron (Fe): 39.5%

- Aluminum (Al): ≤0.15%

- Titanium (Ti): 0.15–0.60%

- Copper (Cu): ≤0.75%

- Silicon (Si): 0.60–1.20%

- Carbon (C): ≤0.1%

- Others: ≤1.0%

Incoloy 825:

- Nickel (Ni): 38.0–46.0%

- Chromium (Cr): 19.5–23.5%

- Iron (Fe): 22.0%

- Titanium (Ti): 0.6–1.2%

- Copper (Cu): 1.5–3.0%

- Silicon (Si): 0.5%

- Tin (Sn): 0.2%

- Others: ≤1.0%

Incoloy 800H:

- Nickel (Ni): 30.0–35.0%

- Chromium (Cr): 19–23%

- Iron (Fe): 39.5%

- Aluminum (Al): ≤0.15%

- Titanium (Ti): 0.15–0.60%

- Copper (Cu): ≤0.75%

- Silicon (Si): 0.60–1.20%

- Carbon (C): 0.05–0.10%

- Others: ≤1.0%

Incoloy 925:

- Nickel (Ni): 42.0–46.0%

- Chromium (Cr): 22.0–24.0%

- Iron (Fe): 22.0%

- Aluminum (Al): ≤0.15%

- Titanium (Ti): ≤2.5%

- Copper (Cu): ≤2.5%

- Sulfur (S): ≤0.030%

- Silicon (Si): ≤0.50%

- Others: ≤1.0%

Alloy Material Selection Suggestions

In terms of material selection, quality is paramount. Our proud series of alloy steels, including C276, Inconel 625, Inconel 718, Inconel 825, Inconel X-750, Monel 400, Monel K-500, Incoloy 800, Incoloy 825, Incoloy 800H, and Incoloy 925, are ideal choices for your engineering projects.

These alloy steel materials not only boast excellent corrosion resistance but also possess outstanding mechanical properties, including tensile strength, yield strength, elongation, and hardness, ensuring stable operation and long-term usage of your projects in various harsh environments.

Our products conform to international standards, ensuring reliable quality and suitability for a wide range of applications, such as chemical industry, aerospace, and marine engineering. Whether your project requires high temperature resistance, corrosion resistance, high strength, or other special properties, our series of alloy steels can meet your needs.

By choosing our alloy steels, you will obtain higher quality materials, more reliable engineering solutions, and longer service life. We are committed to providing customers with the highest quality products and the most satisfactory services.