ASTM A242

- Home

- Products

- Carbon Steel Stocks

- ASTM A242

Basic Info

The ASTM A242 standard specifies a weather resistant steel plate designed to provide excellent corrosion resistance in atmospheric environments. This low alloy high-strength steel is suitable for outdoor structures, such as bridges, buildings, and manufacturing equipment. Under natural exposure conditions, it forms a stable oxide layer, providing additional protection and maintaining its structural strength and appearance. ASTM A242 steel plate has excellent weather resistance characteristics and is suitable for engineering projects under various climatic conditions.

Characteristics

Corrosion Resistance: ASTM A242 steel is renowned for its excellent resistance to atmospheric corrosion, making it suitable for outdoor structures exposed to harsh environmental conditions.

High-Strength: This steel grade offers high tensile strength, providing structural integrity and load-bearing capacity to construction projects.

Weldability: ASTM A242 steel exhibits good weldability, allowing for ease of fabrication and construction without compromising its structural integrity.

Formability: It possesses good formability, enabling it to be shaped and molded into various structural components to meet specific design requirements.

ASTM A242 Data Sheet

ASTM A529/A529M: High-Strength Low-Alloy Structural Steel

ASTM A242 Type 1: Weathering Steel, Atmospheric Corrosion Resistance

ASTM A242 Type 2: Weathering Steel, Atmospheric Corrosion Resistance

Plates

- Width Range (mm): 600 – 2500

- Thickness Range (mm): 6 – 200

- Tolerances: Width and thickness tolerances specified by ASTM

- Notes: –

Sheets

- Width Range (mm): 600 – 2500

- Thickness Range (mm): 0.5 – 200

- Tolerances: Width and thickness tolerances specified by ASTM

- Notes: –

Strips

- Width Range (mm): 12.7 – 609.6

- Thickness Range (mm): 0.4 – 6.4

- Tolerances: Width and thickness tolerances specified by ASTM

- Notes: –

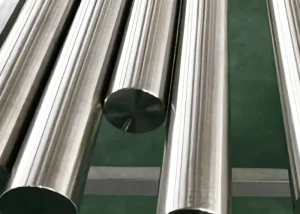

Bars

- Width Range (mm): 20 – 1500

- Thickness Range (mm): 2 – 400

- Tolerances: Width and thickness tolerances specified by ASTM

- Notes: Round, square, hexagonal, and other shapes available

USA

- Equivalent Grade: ASTM A588

- Standard: ASTM A588/A588M

- Notes: High-strength low-alloy structural steel

China

- Equivalent Grade: Q355NH

- Standard: GB/T 4171-2008

- Notes: Weathering steel, atmospheric corrosion resistance

Japan

- Equivalent Grade: JIS SPA-H

- Standard: JIS G3125-2004

- Notes: Atmospheric corrosion resisting steel

Australia

- Equivalent Grade: WR 50A

- Standard: AS/NZS 1594:2002

- Notes: Weather-resistant structural steel

- Carbon (C): 0.15 – 0.22

- Manganese (Mn): 0.80 – 1.25

- Phosphorus (P): 0.04 (max)

- Sulfur (S): 0.05 (max)

- Silicon (Si): 0.30 – 0.65

- Chromium (Cr): 0.40 – 0.65

- Nickel (Ni): 0.40 (max)

- Copper (Cu): 0.25 – 0.40

- Vanadium (V): 0.02 – 0.10

Tensile Strength

- Value: 485 – 620 MPa

- Testing Method: ASTM A370

Yield Strength

- Value: 345 MPa (min)

- Testing Method: ASTM A370

Elongation

- Value: 20% (min)

- Testing Method: ASTM A370

Charpy V-notch Impact Test

- Value: 27 J (20 ft-lb) at -20°C (-4°F)

- Testing Method: ASTM A673, A588, A606

Hardness (Brinell)

- Value: 137 – 187 HB

- Testing Method: ASTM E10

Shear Modulus

- Value: 75 GPa (10.9 x 10^6 psi)

Bulk Modulus

- Value: 160 GPa (23.2 x 10^6 psi)

Poisson’s Ratio

- Value: 0.27

Elastic Modulus

- Value: 190 – 210 GPa (27.6 – 30.5 x 10^6 psi)

Compressive Strength

- Value: 305 – 368 MPa (44,200 – 53,400 psi)

Fatigue Strength (Endurance Limit)

- Value: 186 – 225 MPa (27,000 – 32,600 psi)

- Testing Method: ASTM E466

Shear Strength

- Value: 275 MPa (39,800 psi)

Ultimate Bearing Strength

- Value: 620 MPa (89,900 psi)

Ultimate Shearing Strength

- Value: 310 MPa (44,960 psi)

Cutting

- Method: Oxy-fuel, Plasma, Laser, Saw, Shearing

- Guidelines: Use sharp, clean cutting tools. Avoid excessive heat input. Preheat if necessary. Maintain a clean cutting surface.

Forming

- Method: Hot or Cold Forming, Bending

- Guidelines: Use proper tooling and equipment. Follow manufacturer’s recommendations for bending radius. Avoid sharp bends. Preheat if necessary.

Machining

- Method: Drilling, Milling, Turning

- Guidelines: Use high-speed tools with proper cutting angles. Use cutting fluids to dissipate heat. Monitor for work hardening.

Welding

- Method: SMAW, GTAW, GMAW, FCAW, SAW

- Guidelines:

- Clean base metal thoroughly. Preheat to recommended temperature range. Use low-hydrogen electrodes/fillers. Control interpass temperature.

- Use stringer beads for SMAW. Maintain proper travel speed and arc voltage. Back-gouge and back-weld if required. Post-weld heat treatment may be necessary.

- For GMAW and FCAW, use proper shielding gas and wire. Control arc length and travel speed. Perform preheating and post-weld heat treatment as required.

- For GTAW, maintain proper gas coverage and electrode size. Use proper filler materials and maintain cleanliness.

- For SAW, use appropriate flux and wire combinations. Control welding parameters to minimize heat input. Preheat and post-heat as required.

Cost-Effectiveness and Sustainability of ASTM A242

Cost-effectiveness and sustainability are key considerations when evaluating materials like ASTM A242 steel. This high-strength low-alloy structural steel offers numerous advantages throughout its lifecycle that contribute to both economic and environmental sustainability.

Firstly, ASTM A242 steel’s durability ensures a long service life, reducing the frequency of repairs and replacements. Its exceptional corrosion resistance properties make it particularly suitable for outdoor applications, where exposure to harsh environmental conditions can lead to premature degradation of other materials. By withstanding corrosion, ASTM A242 steel minimizes the need for costly maintenance interventions, saving both time and money over the long term.

Moreover, the low maintenance requirements of ASTM A242 steel further enhance its cost-effectiveness. Unlike materials that require regular upkeep, such as coatings or protective treatments, ASTM A242 steel can often be installed and left to perform without significant ongoing attention. This not only reduces maintenance expenses but also minimizes the disruption associated with maintenance activities, leading to additional cost savings.

From a sustainability perspective, ASTM A242 steel’s longevity and low maintenance contribute to environmental benefits. By extending the lifespan of structures and reducing the consumption of resources associated with maintenance and repair activities, ASTM A242 steel helps conserve materials and energy over time. Additionally, its recyclability at the end of its service life further enhances its sustainability credentials, as it can be repurposed or recycled into new steel products, minimizing waste and environmental impact.

In summary, ASTM A242 steel offers a compelling combination of cost-effectiveness and sustainability, making it a preferred choice for a wide range of construction and infrastructure projects. Its durability, low maintenance requirements, and recyclability contribute to both economic savings and environmental stewardship, aligning with modern sustainability goals and practices.