ASTM A269

- Home

- Products

- Stainless Steel Stocks

- ASTM A269

Basic Info

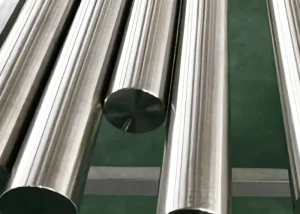

ASTM A269 sets the standards for seamless and welded austenitic stainless steel tubing for general service. This standard covers a wide range of sizes and grades used in applications like mechanical, structural, and decorative uses. It ensures the quality, consistency, and durability of stainless steel tubing for various industries.

Characteristics

High Purity: ASTM A269 specifies seamless and welded austenitic stainless steel tubing for general service, ensuring high purity and cleanliness of the material.

Mechanical Integrity: It provides excellent mechanical properties, including high strength and toughness, ensuring reliability in demanding environments.

Surface Finish: A269 tubing typically has a smooth surface finish, making it suitable for sanitary and high-precision applications.

Resistance to Corrosion: Stainless steel tubing under A269 offers exceptional resistance to corrosion, making it ideal for corrosive environments.

ASTM A269 Data Sheet

TP304/304L

TP316/316L

TP321/321H

TP347/347H

TP317/317L

Round

Outside Diameter (OD) Range: 1/8″ to 24″ (10.31mm to 610mm)

Wall Thickness (WT) Range: SCH 5S to SCH 80S (0.035″ to 0.500″)

Tolerance on OD: +0.125″/-0.025″ (+3.18mm/-0.64mm)

Tolerance on WT: ±10%

Round

Outside Diameter (OD) Range: 1/8″ to 20″ (10.31mm to 508mm)

Wall Thickness (WT) Range: SCH 5S to SCH 80S (0.035″ to 0.500″)

Tolerance on OD: +0.125″/-0.025″ (+3.18mm/-0.64mm)

Tolerance on WT: ±10%

European Union (EN)

Equivalent Steel Grades: EN 10216-5 (1.4301, 1.4307, 1.4401, 1.4404, 1.4435, 1.4878, 1.4550, 1.4541, 1.4948)

Japan (JIS)

Equivalent Steel Grades: JIS G3469 (SUS304TP, SUS304LTP, SUS316TP, SUS316LTP, SUS321TP, SUS347TP, SUS347HTP)

China (GB)

Equivalent Steel Grades: GB/T 14976 (0Cr18Ni9, 00Cr19Ni10, 0Cr18Ni10Ti, 00Cr18Ni11Nb, 00Cr17Ni14Mo2)

Tensile Strength (MPa)

Grade TP304 (UNS S30400): ≥ 515

Grade TP304L (UNS S30403): ≥ 485

Grade TP316 (UNS S31600): ≥ 515

Grade TP316L (UNS S31603): ≥ 485

Grade TP321 (UNS S32100): ≥ 515

Grade TP321H (UNS S32109): ≥ 515

Grade TP347 (UNS S34700): ≥ 515

Grade TP347H (UNS S34709): ≥ 515

Grade TP317 (UNS S31700): ≥ 515

Grade TP317L (UNS S31703): ≥ 515

Yield Strength 0.2% Offset (MPa)

Grade TP304 (UNS S30400): ≥ 205

Grade TP304L (UNS S30403): ≥ 170

Grade TP316 (UNS S31600): ≥ 205

Grade TP316L (UNS S31603): ≥ 170

Grade TP321 (UNS S32100): ≥ 205

Grade TP321H (UNS S32109): ≥ 205

Grade TP347 (UNS S34700): ≥ 205

Grade TP347H (UNS S34709): ≥ 205

Grade TP317 (UNS S31700): ≥ 205

Grade TP317L (UNS S31703): ≥ 205

Elongation (%)

Grade TP304 (UNS S30400): ≥ 35

Grade TP304L (UNS S30403): ≥ 35

Grade TP316 (UNS S31600): ≥ 30

Grade TP316L (UNS S31603): ≥ 30

Grade TP321 (UNS S32100): ≥ 35

Grade TP321H (UNS S32109): ≥ 35

Grade TP347 (UNS S34700): ≥ 35

Grade TP347H (UNS S34709): ≥ 35

Grade TP317 (UNS S31700): ≥ 35

Grade TP317L (UNS S31703): ≥ 35

Hardness (Brinell)

Grade TP304 (UNS S30400): ≤ 192

Grade TP304L (UNS S30403): ≤ 192

Grade TP316 (UNS S31600): ≤ 192

Grade TP316L (UNS S31603): ≤ 192

Grade TP321 (UNS S32100): ≤ 192

Grade TP321H (UNS S32109): ≤ 201

Grade TP347 (UNS S34700): ≤ 201

Grade TP347H (UNS S34709): ≤ 201

Grade TP317 (UNS S31700): ≤ 192

Grade TP317L (UNS S31703): ≤ 192

Rockwell Hardness (HRB)

Grade TP304 (UNS S30400): ≤ 90

Grade TP304L (UNS S30403): ≤ 90

Grade TP316 (UNS S31600): ≤ 90

Grade TP316L (UNS S31603): ≤ 90

Grade TP321 (UNS S32100): ≤ 90

Grade TP321H (UNS S32109): ≤ 95

Grade TP347 (UNS S34700): ≤ 95

Grade TP347H (UNS S34709): ≤ 95

Grade TP317 (UNS S31700): ≤ 90

Grade TP317L (UNS S31703): ≤ 90

Rockwell Hardness (HRC)

Grade TP304 (UNS S30400): ≤ 90

Grade TP304L (UNS S30403): ≤ 90

Grade TP316 (UNS S31600): ≤ 90

Grade TP316L (UNS S31603): ≤ 90

Grade TP321 (UNS S32100): ≤ 90

Grade TP321H (UNS S32109): ≤ 95

Grade TP347 (UNS S34700): ≤ 95

Grade TP347H (UNS S34709): ≤ 95

Grade TP317 (UNS S31700): ≤ 90

Grade TP317L (UNS S31703): ≤ 90

Tensile Strength: ≥ 515 MPa (74,775 psi)

Yield Strength (0.2% offset): ≥ 205 MPa (29,732 psi)

Elongation (in 2 inches/50.8 mm): ≥ 35%

Hardness (Brinell): ≤ 192 HB

Forming

ASTM A269 stainless steel tubing can be readily formed and drawn.

Tubing should be annealed after forming to maintain corrosion resistance and ensure proper mechanical properties.

Machining

ASTM A269 stainless steel is readily machinable using standard machining techniques.

Welding

Welding should be performed using appropriate filler materials compatible with the base metal.

Common welding methods include TIG (Tungsten Inert Gas) welding or GTAW (Gas Tungsten Arc Welding) and SMAW (Shielded Metal Arc Welding).

Preheating is generally not required, but post-weld heat treatment may be necessary to restore corrosion resistance and mechanical properties.

ASTM A269 stainless steel tubing should be thoroughly cleaned before welding to remove any contaminants.

Proper shielding gas (argon or argon/helium mix) should be used to prevent oxidation and ensure sound welds.

Welding parameters should be adjusted to minimize distortion and achieve full penetration.

Welds should be inspected using non-destructive testing methods such as visual inspection, radiography, or ultrasonic testing.

Unrivaled Durability: The Corrosion-Defying Power of ASTM A269 Stainless Steel Tubing

ASTM A269 stainless steel tubing stands out for its exceptional corrosion resistance, making it highly sought after by customers across various industries. Its ability to withstand harsh environments and corrosive substances ensures longevity and reliability in critical applications, such as pharmaceuticals, food processing, and marine environments. This corrosion resistance extends to chloride-rich environments, where ASTM A269 materials excel, providing customers with peace of mind regarding the durability of their investments. Moreover, the aesthetic appeal of stainless steel enhances the overall value proposition, adding a premium touch to products. As a result, customers can trust ASTM A269 tubing to deliver superior performance, reduce maintenance costs, and minimize downtime, ultimately enhancing their operational efficiency and bottom line.