Table of Contents

Introduction

In the process of providing coil distribution services to end-users, steel traders often encounter the issue of transverse ridges on the inner rings of steel coils. This defect is also commonly reported to the quality dispute departments at steel mills, where it is referred to as Leading Edge Marks (or Reel Kinks).

What Are Leading Edge Marks (Reel Kinks)?

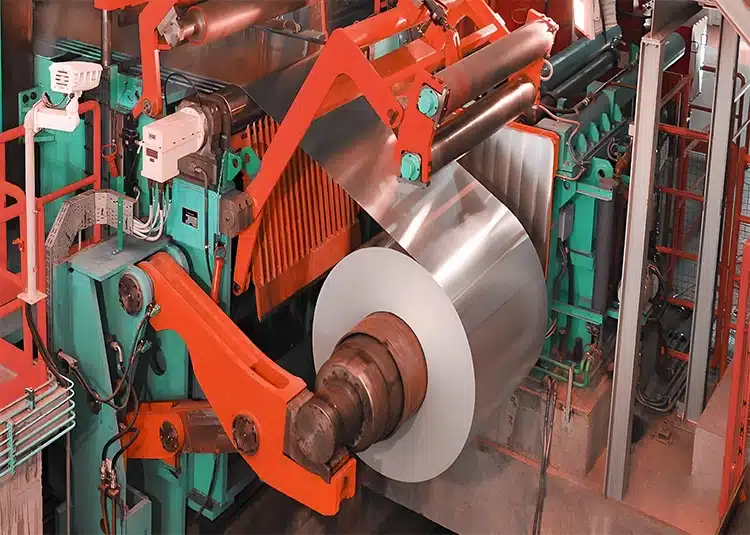

Leading Edge Marks (Reel Kinks) are defects unique to steel coils and are closely related to the coiling process. These marks are formed at the leading edge of the strip steel and are influenced by the coiling machine’s (or uncoiling machine’s) mandrel.

During the coiling process, significant tension is applied to keep the strip steel tight, ensuring sufficient friction between the layers to prevent coil collapse (or flattening). Due to the thickness of the strip steel, any unevenness at the leading edge is transmitted through each layer during the coiling process, eventually forming Leading Edge Marks.

Causes of Leading Edge Marks

By understanding the mechanism behind the formation of Leading Edge Marks, we can derive the following influencing factors:

Leading Edge Thickness (Strip Steel Thickness)

The thicker the leading edge, the higher the protrusion, which increases the likelihood of Leading Edge Marks. For materials with thicknesses above 0.8mm, attention should be paid to this issue.

Yield Strength of the Steel Coil

The lower the yield strength, the softer the material, making it more prone to deformation under pressure. Deep-drawing materials, such as DC06 and DC56D+Z, should be handled with extra care.

Coiling Tension

The higher the coiling tension, the greater the force applied to the leading edge, increasing the chances of Leading Edge Marks. However, the coiling tension must first ensure the formation of a “hard core” to prevent coil deformation. In actual production, if there is folding at the leading edge or a loud tensioning sound after the leading edge is gripped by the coiling machine, this should raise concerns.

Mandrel Material and Shape

Different materials and shapes of the mandrel affect the severity of Leading Edge Marks. For example, steel mandrels cause more severe marks due to their hardness, while rubber mandrels result in lighter marks (though they cannot completely prevent the issue).

How To Improve Leading Edge Marks?

Does the appearance of Reel Kinks automatically indicate a quality issue, and can it be raised as a quality dispute?

The answer is no.

The thickness, yield strength, coiling tension, and mandrel parameters are inherent material properties that cannot be changed. Therefore, for certain materials like 2.0mm thick DC06 soft steel, the formation of Leading Edge Marks after coiling is unavoidable.

In the steel industry, the responsibility for improving Leading Edge Marks falls on the straightening equipment used during the uncoiling process, such as the leveling machines on cut-to-length lines or precision straighteners on terminal continuous punching production lines.

- Precision Levelers in Cut-to-Length Lines: These machines are key to improving Leading Edge Marks. The equipment’s capacity, maintenance condition, and the operator’s skill all directly affect the improvement. Typically, multi-roll, thin-roll, and high-pressure straightening equipment provide better leveling capabilities.

- Mini Levelers for Slit Products: If the end product is used in continuous stamping, a small leveling machine should be installed in front of the stamping equipment. Proper maintenance and adjustment of this mini straightener are critical to reducing the impact of Leading Edge Marks.

Conclusion

Furthermore, for end-users, the saying “you get what you pay for” holds true—reasonable pricing is necessary to support high-quality requirements.

Steel sheets cut from coils are not 100% usable. When calculating the number of usable sheets, it is necessary to consider the reasonable defect allowance specified by national standards, and the cost of this loss should be factored into the material purchase price.

#1 GB/T 5213-2019 Cold-Rolled Low-Carbon Steel Sheets and Strips, Section 6.6.3, states: “For steel strips, as there is no opportunity to remove the defective portion, delivery with defects is allowed, but the defective portion should not exceed 6% of the total length of each coil.”

Understanding the principles, communicating effectively, and rationally addressing differences are key to enhancing supply chain efficiency as cooperation deepens. Excessive pursuit of low prices may lead to increased costs due to higher scrap rates, ultimately raising the overall cost of the manufacturing chain and representing a loss of social efficiency.

If you are looking for more detailed insights into steel defects or need guidance on material selection, visit our Metal Library for a wealth of technical information.

Ready to purchase high-quality steel materials? Explore a wide range of steel products at AlloyXpert, where we ensure both quality and reliability in every order.

Read More:

How to Properly Store Stainless Steel Coils to Prevent Damage