Introduction

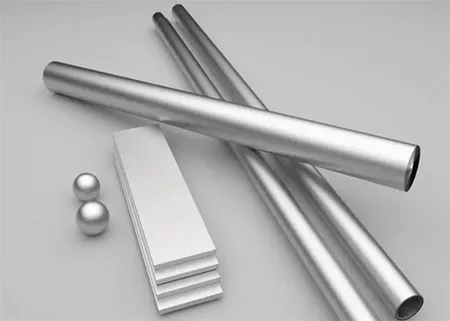

CRES 17-4 PH stainless steel is strong. This guide encompasses the uses of turbines as well as valves. This is reliable steel, with the tensile strength of 1100 and the hardness of 40 HRC.

It also explores its composition, chromium, and nickel. Find out how it works better in the various parts.

What is CRES 17-4 PH Stainless Steel?

CRES 17-4 PH stainless steel is a robust material. It has high tensile strength equal to about 1100 Mpa. This steel resists corrosion. The H900 temper provides a hardness of approximately 40 HRC.

It is used in turbine blades and valves. They refer to it as precipitation-hardening steel. It has chromium and nickel in its composition.

| Property | Description | 17-4 PH Stainless Steel | 304 Stainless Steel | 316 Stainless Steel | 440C Stainless Steel | 410 Stainless Steel |

| Primary Element | Main Component | Fe, Cr, Ni | Fe, Cr, Ni | Fe, Cr, Ni, Mo | Fe, Cr, C | Fe, Cr |

| Chromium (Cr) | Chromium Content (%) | 15-17 | 18-20 | 16-18 | 16-18 | 11.5-13.5 |

| Nickel (Ni) | Nickel Content (%) | 3-5 | 8-10 | 10-14 | 0.75 | 0.75 |

| Copper (Cu) | Copper Content (%) | 3-5 | 0.75 max | 0.75 max | 0.5 max | 0.5 max |

| Molybdenum (Mo) | Molybdenum Content (%) | 0.25 max | – | 2-3 | – | – |

| Carbon (C) | Carbon Content (%) | 0.07 max | 0.08 max | 0.08 max | 0.95-1.2 | 0.15 max |

| Mechanical Properties | Yield Strength (MPa) | 1,035 | 215 | 290 | 450 | 275 |

Table on Chemical Composition of CRES 17-4 PH Stainless Steel!

What Are the Advantages of Using CRES 17-4 PH Stainless Steel?

CRES 17-4 PH stainless steel is great. It possesses unique characteristics that make it suitable for various purposes. Let’s look!

· High Strength

CRES 17-4 PH stainless steel is very strong. It has 15% chromium and 4% nickel. This metal is used to support heavy items. Its yield strength is 1000 MPa. It is used by airplanes for important parts.

It doesn’t bend easily. It works well in hard jobs. Engineers like it for being hard. This alloy also contains Cu. They use it for making shafts. It performs very well where it is most needed.

· Toughness

It is truly remarkable how strong CRES 17-4 PH stainless steel is. It contains a martensitic structure. This steel can take a pounding. It has high Charpy impact value. Cars use it for the suspension system.

It is especially appreciated by engineers because the plastic does not crack easily. One of them is that it remains stable with pressure. They use it for turbine blades. This metal is good to use where things get rough. It is powerful as well as hard.

· Good Weldability

CRES 17-4 PH stainless steel is easy to weld. It has 0.07% C. Welders like it. Precipitation hardening makes it better. It can use many welding methods. SMAW is common. TIG welding works too.

This metal welds easily. It doesn’t crack much. Its microstructure helps welding. It is selected by engineers for crucial connections.

· Heat Treatment

Heat treatment improves the properties of CRES 17-4 PH stainless steel. The first is solution annealing at 1040°C. This step emulsifies everything. This is followed by aging at 480°C.

That is why engineers make it tough with heat treatment. It alters the metal’s hardness. It also aids in preventing rust at this step. This steel is very much in need of heat treatment. It assists it to function effectively.

· Fatigue Resistance

Fatigue resistance means the CRES 17-4 PH stainless steel does not weaken. It has high fatigue strength. The steel does not fracture under repeated stress. Engineers subject it to rotary bending.

This metal is used for making moving parts. It is effective when used in spinning shafts. Its design prevents such breakdowns from occurring. Its microstructure enables it to have a long life cycle. It is used by engineers for many cycles. This metal is perfect for hard work.

Is 17-4 Stainless Steel Good?

CRES 17-4 PH stainless steel is good. It has a tensile strength of 1200 MPa. This steel is not prone to corrosion. It contains chromium, nickel, and copper in the mix. It is applied in boat propellers. It is used in marine parts. Due to H1150 condition it has better balance and flexibility.

What is the Difference Between 17-4 and 304 Stainless Steel?

17-4 and 304 stainless steel are significant. Each one of them has its own purpose. Now, what makes them special?

· Mechanical Properties

CRES 17-4 PH steel is strong. It has 1100 MPa strength and 40-HRC hardness. This makes parts such as valves and gears rigid. The tensile strength is useful in a high stress application area.

Fatigue resistance is synonymous with lasting long. CRES 17-4 PH is employed as aircraft components. These numbers demonstrate its strength.

| Property | CRES 17-4 PH Steel | Test Temperature | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Section Shrinkage (%) |

| Strength | 1100 MPa | 20°C | 1280 | 1310 | 11.2 | 67.8 |

| Hardness | 40 HRC | 20°C | 1280 | 1310 | 11.2 | 67.8 |

| Fatigue Resistance | High | 20°C | 1280 | 1310 | 11.2 | 67.8 |

| Application Temperature | – | 20°C | 1280 | 1310 | 11.2 | 67.8 |

| Elongation at Break (%) | 11.2 | 20°C | 1280 | 1310 | 11.2 | 67.8 |

| Section Shrinkage (%) | 67.8 | 20°C | 1280 | 1310 | 11.2 | 67.8 |

Table on Mechanical Properties of CRES 17-4 PH!

· Thermal Properties

CRES 17-4 PH steel has good thermal stability. Thermal conductivity is 17.3 W/m•K, transferring heat quickly. The coefficient of thermal expansion is 10.8 µm/m•°C. This keeps it stable.

It works up to 315°C. This is good for turbines and heat exchangers. These numbers make it handle heat better.

· Machinability

CRES 17-4 PH steel is easy to cut. Its machinability rating is 50. Cutting speed is 45 m/min. The hardness of 40 HRC does help. CNC milling and drilling are effective.

This steel produces smooth surfaces. Resilience means tools should be long lasting. It is useful for creating things rapidly.

· Cost Comparison

CRES 17-4 PH steel is more expensive than 304 steel. The higher cost is as a result of enhanced properties. It is stronger and longer lasting. This steel is worth the price when it comes to important jobs. Another advantage is that while the acquisition cost is high, the cost of repairs is low. It’s preferable when money is tight.

· Typical Uses

CRES 17-4 PH steel is applied to airplanes and boats. It is strong for aircraft parts. The corrosion resistance aids in water. It is used in pump shafts and turbine blades. This steel is used by the oil and gas equipment. It is also in medical tools. This steel does many jobs.

· Corrosion Resistance

CRES 17-4 PH steel does not corrode. Chromium content is between 15-17.5%, which forms a protective layer. It performs well in chloride environments. The ability to resist stress corrosion cracking is good.

This means it endures in unfavorable conditions. The steel is suitable for marine and chemical applications. These numbers prove that it does not corrode easily.

| Property | 17-4 Stainless Steel | 304 Stainless Steel |

| Mechanical Properties | Tensile Strength: 930-1080 MPa | Tensile Strength: 515-720 MPa |

| Yield Strength: 725-1035 MPa | Yield Strength: 215-505 MPa | |

| Hardness: HRC 28-42 | Hardness: HRC 18-28 | |

| Thermal Properties | Thermal Conductivity: 18 W/m·K | Thermal Conductivity: 16.2 W/m·K |

| Melting Point: 1400-1450°C | Melting Point: 1400-1450°C | |

| Machinability | Moderate, Use carbide tools | Good, Easily machined |

| Cost Comparison | Higher cost | Lower cost |

| Corrosion Resistance | High, Resists pitting | Good, General corrosion |

Table on Difference Between 17-4 and 304 Stainless Steel!

What Grade is 17/4 Stainless Steel?

CRES 17-4 PH stainless steel is Grade 630. ASTM 17-4PH is a precipitation-hardening martensitic stainless steel composed of copper and niobium/columbium. This grade contains 17% chromium and 4% nickel. The carbon content is relatively small, at around 0.07%. They use it in springs.

Is 17-4 Machinability Better Than 304?

CRES 17-4 PH steel machines better than 304 steel. Its machinability rating is 65%. This makes cutting and shaping easier. The steel forms chips well. They use it for accurate parts. It gives better surface finish. It is favored by engineers when it comes to intricate tasks of machining.

Is 17/4 Stainless Brittle?

CRES 17-4 PH stainless steel is not brittle. It has a toughness of 45 J. This steel is good at handling impacts. It has 10% ductility. They incorporate it in airplane parts. The H1150 condition enhances flexibility. Engineers trust it. This steel is strong and safe.

Is 17/4 SS Magnetic?

CRES 17-4 PH stainless steel is magnetic in nature. Its magnetic permeability is 1.3. This property assists in sensors. The steel has iron in it and therefore it is magnetic. It is used in magnetic couplings. They depend on it for support. The H900 condition enhances magnetic properties. This steel attracts magnets.

What is the Other Name for 17-4 Stainless Steel?

The material known as 17-4 stainless steel has many different names. They are different but refer to the similar ‘strong steel’. Why don’t we get to know more about them?

· UNS S17400

Known as UNS S17400, CRES 17-4 PH stainless steel is strong. It is used in valves and gears. The tensile strength is 1100. Heat treatment makes it difficult. They incorporate chromium, nickel, and copper.

Engineers trust it. The yield strength is 1000. UNS S17400 is magnetic. This steel does not corrode quickly. It is used by factories for safe parts. UNS S17400 is very reliable.

· AISI 630

CRES 17-4 PH stainless steel is also known as AISI 630. It has copper and niobium. The hardness level is H900. This steel is in turbine blades. AISI 630 resists rust. The tensile strength is 1310.

Yield strength reaches 1180. They use it for challenging tasks. Heat treatment helps. AISI 630 is magnetic. It is used to make important parts of factories. AISI 630 is strong.

· X5CrNiCuNb16-4

CRES 17-4 PH stainless steel in Europe is X5CrNiCuNb16-4. It contains chromium and nickel. The minimum yield strength is 1030. They are employed in pump shafts. X5CrNiCuNb16-4 resists rust. The tensile strength is 1150. Heat treatment makes it difficult. They use it in airplanes.

Engineers like its strength. It’s magnetic. X5CrNiCuNb16-4 has good properties. Industries use it for large projects.

· 1.4542

CRES 17-4 PH stainless steel, known as 1.4542, has high strength. Yield strength is 1000. Yes, it has nickel and copper. Tensile strength is 1070. This steel is in medical tools. Heat treatment makes it difficult.

It’s magnetic. It is used in chemical plants. 1.4542 is tough. It is used by factories for crucial activities. 1.4542 doesn’t rust easily. It’s very reliable.

What is 17-4 PH Steel Used For?

This type of steel has many applications. It is effective and useful in many areas. Well, let me share some of them with you!

· Pump Shafts

CRES 17-4 PH stainless steel is used in pump shafts. It possesses a tensile strength of 1000 MPa. This steel withstands wear. It lasts long. They use it for its dependability. The H1025 condition assists it work better. It is relied on in pumps by engineers.

· Aircraft Fittings

CRES 17-4 PH stainless steel is used in aircraft fittings. Its tensile strength is 1310 MPa. This makes it strong. One of the advantages of steel is that it has high fatigue strength. They use it for the operations of their landing gear. It ensures safety. Engineers like it for the crucial components.

· Nuclear Waste Containers

Nuclear waste containers use CRES 17-4 PH stainless steel. It resists corrosion well. They opt for it for safety reasons. Its impact strength is 50 J. This means that it is strong. The H1100 condition makes it stable.

· Fasteners

Fasteners utilize CRES 17-4 PH stainless steel. The strength of the steel is measured at 1100 MPa. It makes strong connections. This steel contains copper for added hardness. They use it for bolts and nuts. The H900 condition makes it difficult.

· Food Processing

CRES 17-4 PH stainless steel is applied in food machines. It resists rust. They use it for mixers. This material cleans easily. The H1150 condition makes it difficult. It keeps food safe.

· Petrochemical

CRES 17-4 PH stainless steel is used by petrochemical industries. It has a tensile strength of 1400 MPa. It resists harsh chemicals. It is used in valves. The H1075 condition is beneficial in preventing damages.

What is the ASTM Equivalent of 17-4 PH Stainless Steel?

ASTM designations correspond to 17-4 PH steel. These names prove that it meets the right standards. We should learn more about them!

· ASTM A564

Cres 17-4 PH stainless steel can be classified as a unique type of metal. It is strong. This metal has a tensile strength of 1100 MPa. It is shiny because of the chromium (Cr).

It is used by engineers for bolts, pins, and screws. They like it because it does not rust. It also contains nitrogen (N) and nickel (Ni). This steel is very hard. The material has a hardness of 36 HRC. Everybody loves how powerful it is. It improves the performance of machines.

· AMS 5643

Cres 17-4 PH stainless steel is cool. Engineers love it. The tensile strength is 1200 Mega Pascals. It has molybdenum (Mo) and copper (Cu). That makes it very strong. This makes it very strong.

They employ it in the production of gears, springs, and valves. It is durable in that it cannot easily be worn out. The yield strength is 1000 MPa. It has a Rockwell hardness of 40 HRC. This material is not very flexible. It aids in flying high for airplanes. It is used in large machines by everyone.

· AMS 5622

Cres 17-4 PH stainless steel is just great. It has a tensile strength of 900 MPa. It contains silicon (Si) and manganese (Mn). This makes it very hard. It is used by the engineers for the blades of the turbines and other components of the engines. It resists heat well. The yield strength is 800 MPa.

This steel is used in many areas. The hardness is 32 HRC. They like its durability. It assists cars to move at a high speed. The material is present in many tools.

· EN 1.4542

Cres 17-4 PH stainless steel is great. It has a tensile strength of 1050 Mega Pascal. This steel is alloyed with phosphorus (P) and sulfur (S). It is used by engineers for shafts, fittings and rods.

It resists corrosion. The yield strength is 950 MPa. The hardness is 38 HRC. This material is very strong. Everyone likes its reliability. They use it in bridges and buildings. The steel ensure that everything is secure.

How Hard is 17-4 PH Stainless Steel?

CRES 17-4 PH is known as 17-4 PH Stainless Steel and it is very hard at 40 HRC. It is applied in gears, valves, and pumps. This steel has carbon: 0.07%, copper: 0.04%, and chromium: 0.17%.

The ultimate tensile strength is 160 ksi. Its best use is under high pressure. That is why many engineers prefer it.

How to Properly Heat Treat 17-4 PH Stainless Steel?

It is crucial to heat treat 17-4 PH steel. It makes it strong and ready for use. Heat treatment methods include H900, H900M, H1100, H1025, H1025M, H1150, H1150M, and H1075. And that’s how it is done!

· Steps

First, rinse and dry CRES 17-4 PH stainless steel. Bake it at a temperature of 450°C for one hour. Cool in oil or air. It hardens. Then cool it to room temperature. This makes it strong. The parts are now ready.

· Procedures

Preheat CRES 17-4 PH stainless steel part to 1900°F for thirty minutes. Then, quench it. This makes it hard. Heat the steel at a temperature of 900°F for 1 hour. Cool it down. This finishes the procedure.

· Effects

Strengthening CRES 17-4 PH stainless steel make it tough with 1000 MPa tensile strength. This improves wear resistance. Its structure is martensitic. Corrosion resistance increases. The parts are durable. The process stabilizes them. They are effective when it comes to challenging environments.

· Properties

CRES 17-4 PH stainless steel is strong. It contains 17% chromium and 4% nickel. It has a hardness of approximately 38 HRC. It resists corrosion. Elongation is 20%. It has high yield strength. This is a very useful alloy.

· Conditions

Soak CRES 17-4 PH stainless steel at 900°F for one hour. Cool to room temperature. This makes it hard. The situation must be ripe. The process prevents stress. They ensure good hardness.

What Are the Welding Considerations for 17-4 PH Stainless Steel?

This steel requires extra precautions when welding. It ensures everything is solid and secure. What do we need to know?

· Techniques

Apply GTAW when welding CRES 17-4 PH stainless steel. Preheat it to 250°F. Use ER630 filler rod. Optimize the arc length. Ensure that the interpass temperature does not exceed 350°F. The weld pool should be small. This prevents cracks. They cool it carefully.

· Challenges

It is difficult to weld CRES 17-4 PH stainless steel. Its hardness is 38 HRC that raises the cracking probability. Temperature control is key. Use low hydrogen electrodes. Preheat to 300°F consistently. The use of post-weld heat treatment at 600°F does help. This keeps the weld strong.

· Post-weld Treatment

Preheat CRES 17-4 PH stainless steel to 1150°F. Hold for one hour. Allow it to come down to room temperature. This relieves stress. They refer to it as stress relief. Effective cooling enhances the strength of the weld. This leads to strengthening and hardening of the parts.

· Properties

CRES 17-4 PH stainless steel has 16.5% chromium, 4.5% copper. It has a hardness of 40 HRC. The tensile strength is 900 MPa. It is tough and machines well. They use it for many parts. The alloy is universal and trustworthy.

· Procedures

Polish the CRES 17-4 PH stainless steel. Preheat it to 300°F. Use SMAW. Keep the arc short. Inter-pass temperature must not exceed 450°F. Use E630 electrodes. Cool the weld slowly. Inspect the weld. This ensures that the weld is good.

· Effects

Welding CRES 17-4 PH stainless steel increases the strength of the material. The tensile strength rises to 950 MPa. Hardness increases. Corrosion resistance stays high. Parts become more durable. Welds are tough. This treatment makes them work well. They are reliable.

How Does 17-4 PH Stainless Steel Perform in Corrosive Environments?

This steel performs well in tough areas. It resists corrosion and remains tough. Alright, let’s see how it does this!

· Corrosion Resistance

CRES 17-4 PH stainless steel does not corrode easily. It has 15% Cr and 3.5% Mo, which makes it highly resistant to saltwater. It is tested in extreme conditions. The parts don’t rust. This is important in many applications.

· Best Practices

CRES 17-4 PH stainless steel should be cleaned before use. Preheat it to 200°F. Use TIG welding. Interpass temperature must be kept at 300°F. Cool parts slowly. Inspect for cracks. This ensures that the welds formed are strong and resistant to rusting.

· Environments

CRES 17-4 PH stainless steel is not sensitive to salty and acidic environments. It works at temperatures up to 750 °F. The material resists marine and chemical environments. It is used in oil rigs and chemical plants. It resists corrosion.

· Applications

CRES 17-4 PH stainless steel is used in marine propellers and oil rig parts. It is also in food machines and airplane parts. It is the most suitable material because of its outstanding corrosion resistance and strength properties. They depend on it for their important parts.

· Properties

CRES 17-4 PH stainless steel has 15% Cr and 3.5% Mo. Its hardness is 42 HRC. The tensile strength is 950 MPa. It does not rust and wears well. The material is well resistant and very hard. It is applied in a variety of fields.

What Are the Typical Mechanical Properties of 17-4 PH Stainless Steel?

CRES 17-4 PH steel is, therefore, strong and tough. It has some characteristics which make it suitable for use. Let’s see what they are!

· Tensile Strength

CRES 17-4 PH steel is strong steel. Tensile strength is 1300. It can bear large forces. This helps in valves and gears. They make use of it in areas that require high levels of strength.

The toughness shown by the metal is quite incredible. Durability has been established through stress tests to confirm it is not easily bent. This steel is ideal for use in the construction of airplanes. Load capacity is high.

· Yield Strength

Yield strength of CRES 17-4 PH steel is also crucial. It can take 1000 before it starts to flex. They employ it in shafts. This metal is able to bear a lot of pressure. Springs are another use.

It doesn’t vary its form drastically. The structure stays strong. This is very important. It is also very effective in making machines. It is possible to conclude that the yield performance is quite high.

· Elongation

That is why elongation for CRES 17-4 PH steel matters. It stretches 15% before it fractures. Engineers like this. This is suitable for parts that require flexing. Rivets use it well.

This property enables it to flex without fracturing. It is crucial for bendable parts. The metal flex and does not break. Stretching is important. This feature makes it useful.

· Hardness

CRES 17-4 PH steel is extremely hard. It reaches HRC 38. They check it for stiffness. Tools need this. This metal is not prone to scratching. Bearings use it well. The hard structure is long lasting. It keeps its shape. This is important for durability. Toughness is easy to assess.

· Fatigue Strength

CRES 17-4 PH steel possesses very high fatigue strength. It handles repeated stress. This is helpful in areas of high wear and tear. Gears need this. They rely on the fatigue strength.

The metal has long life spans. Stress cycles do not make it weak. Springs and fasteners require this. Endurance is important. This property makes it reliable.

· Modulus

Modulus in CRES 17-4 PH steel is important. It measures elasticity. The value is 200. They use it in parts that can exert force. This makes it stiff. Engineers count on this.

Beams and frames require it. It keeps structures strong. This means that the flexibility of the metal is just right. This feature stabilizes designs.

| Property | Metric | Value | Unit | Condition | Notes | Symbol |

| Tensile Strength | Ultimate | 1,040 – 1,190 | MPa | H900 | High temperature | σUTS |

| Yield Strength | 0.2% Offset | 960 – 1,065 | MPa | H900 | Post-aging | σYS |

| Elongation | At Break | 8 – 12 | % | H900 | Ductility measure | εf |

| Hardness | Rockwell C | 35 – 38 | HRC | H900 | Surface hardness | HRC |

| Fatigue Strength | Endurance Limit | 400 – 620 | MPa | H900 | Cyclic loading | σf |

| Modulus | Elastic Modulus | 200 | GPa | Room Temp | Stiffness measure | E |

Table on the Mechanical Properties of 17-4 PH Stainless Steel!

What Are the Common Processing Methods for 17-4 PH Stainless Steel?

To process this steel, certain special procedures are required. These steps make it ready for many uses. Let’s know what they are!

· Forging

It is heated to 1038°F and then forged with hammers. This makes parts like shafts and gears. This is where the high strength of CRES 17-4 PH stainless steel originates from.

That toughness is necessary in a part that is to be strong. They use presses too. The results are such things as improved grain structure. This method is popular.

· Machining

Machining slices the CRES 17-4 PH stainless steel into desired shapes. CNC tools ensure accuracy. The cutting speeds range up to 2000 rpm. The hardness of the material calls for the use of carbide tools.

It is crucial for making bolts. The process requires coolants for heat dissipation. This ensures smooth surfaces. These tools they employ frequently.

· Heat Treatment

It is heated to 482°, and then it cools down. The CRES 17-4 PH stainless steel becomes harder. This increases to 36 HRC. The strong parts are beneficial to valves.

The above method enhances the wear resistance. They use furnaces for this. The metal becomes stronger. It’s important for performance.

· Welding

It connects CRES 17-4 PH stainless steel with TIG welding. This welds metal with an arc, the heat produced forms a strong union. This is important for airplane parts.

That ensures strong connections. The weld is assisted by the use of filler materials. The process requires shielding gas. This prevents oxidation. They make strong joints.

How to Choose the Right Surface Finish for 17-4 PH Stainless Steel?

Selecting the most appropriate surface is crucial. That enhances the appearance and performance of the steel. Well, let’s discover how to do that!

· Surface Finishes

CRES 17-4 PH stainless steel has polished surfaces. It begins with a roughness average (Ra) of 4. Polishing makes Ra 0.2. This is smoother. They use electro-polishing, taking away small particles.

That makes it shiny. Mechanical polishing requires a minimal amount of abrasives. Bright annealing makes it shiny like a mirror.

· Criteria

Selecting CRES 17-4 PH stainless steel requires criteria. Its tensile strength is 1200 Mega Pascals. The yield strength of this material is 1035 MPa. They verify hardness, 35 HRC.

Fatigue resistance is crucial. Elongation is 10%. The coefficient of thermal expansion is 10.8. Checking these will guarantee high performance.

· Applications

CRES 17-4 PH stainless steel is used in many ways. It is used in airplanes. Its strength is high. Medical tools need it. Corrosion resistance is crucial. This steel is used in the manufacture of valves and gears. They must be durable. This one works well in tough conditions.

· Types

There are different varieties of CRES 17-4 PH stainless steel. H900 type is 44 HRC hard. They use it for strong needs. H1025 type is 38 HRC hard. It is ideal for medium power usage. H1150 type is 34 HRC hard. It has an ideal combination of hardness and durability.

· Properties

CRES 17-4 PH stainless steel has certain characteristics. It has high tensile strength. They like its hardness, 35 HRC. Thermal conductivity is 16.2. Yield strength is high. It weighs 7.8. These make it very useful. This steel is relatively good at not rusting.

· Techniques

Various methods enhance CRES 17-4 PH stainless steel. Solution annealing makes it strong. They do precipitation hardening to make it stronger. Machining cuts it well. Grinding uses abrasives. Electro-polishing makes it smooth. Passivation helps resist rust. These make the steel work better.

What Industries Benefit Most from Using 17-4 PH Stainless Steel?

It is used in many industries. It assists them to work effectively and sustains their strength. We will then find out which industries benefit most!

· Aerospace

CRES 17-4 PH stainless steel is used in planes. It requires a tensile strength of 1030 for jet engines. This steel has a working temperature of up to 800 °C, ideal for use in application such as turbine blades.

The frames of airplanes require yield strength of not less than 1310 MPa. It assists in situations where stress is high.

· Oil and Gas

CRES 17-4 PH stainless steel is useful in the oil and gas industry. The valve stems should have a hardness of 40 HRC. Drill bits require resistance to corrosion. It has tensile strength of 1030 which is appropriate for pipelines. It performs well at high pressure.

· Chemical

CRES 17-4 PH stainless steel is employed in chemical areas. Pumps require yield strength of 1310 MPa. Tanks require its hardness at low temperatures. It works well in hard spots.

· Marine

CRES 17-4 PH stainless steel is used in boats. Propeller shafts require protection against rust. The tensile strength of 1030 means it is strong. Boat hulls require its hardness in cold water. This steel has good durability in seawater.

Conclusion

CRES 17-4 PH stainless steel is corrosion resistant with strength of material. Yes, it is good for turbines, valves and so on. This material is widely used in various industries. Visit ALLOYXPERT to learn more. Take the best of this steel. It is therefore the top choice, when it comes to strength, hardness and resistance.