Introduction

Selecting the proper stainless steel bar requires knowledge of the ASTM specifications, AISI designations, tensile strength, and dimensions. This blog helps you decide what type of bar you should go for. We will talk about characteristics, applications, and so on.

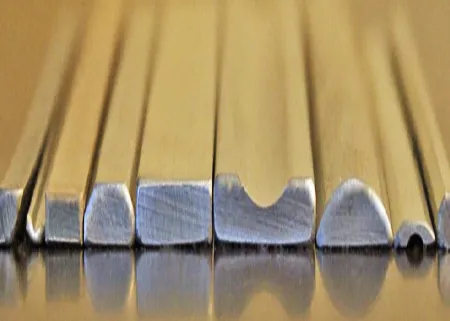

What Are the Different Types of Stainless Steel Bars?

These bars are shiny metal sticks. They are of many forms. This makes them useful. Each type has a different function. Let’s look at them!

· Round Bar

This bar is made from stainless steel and has a cylindrical shape. It is also characterized by a smooth surface. They are widely used in machining operations. Its diameter is 10mm and the tensile strength is 200 Mpa. This bar is incorporated in many machines.

It’s durable and rust-resistant. Some of them can be ordered and cut to specific sizes. This bar is suitable for manufacturing bolts. It also features an AISI 304 grade. People like round bars today. They are used in many fields.

· Flat Bar

The bar used in the production of the utensils is made of stainless steel in the form of a flat rectangle. It measures 5 mm in thickness. These bars are said to be located in brackets.

The width is 20 mm Flat bars have yield strength of 250 Mpa. They can be constructed flexibly.

This bar is situated in frames. They resist corrosion. It is also for this reason that flat bars are easy to weld. The most used grades are the AISI 316 grade. It is also used in various projects. It’s a reliable material.

· Hex Bar

A hex stainless steel bar is a bar with six broad flat faces. It has a nominal diameter of 12mm across flats. They are used in fasteners. This bar is strong and long lasting.

Hex bars have a tensile strength of 210 MPa. It is most suitable for mechanical parts It is most suitable for mechanical parts. They are easily machined. The AISI 303 grade is standard. This bar is rust-proof. They fit into many tools. Hex bars are actually incredibly sturdy.

· Square Bar

This bar is of stainless type and the profile of the section is square. Each side measures 15mm and square bars are used in supports. It has yield strength of 240 Mpa. This bar is very strong indeed. It is made of AISI 304 steel material used in its construction.

This is because they are capable of withstanding wear and tear. Framework employs square bars. That is why it is easily possible to cut them. This bar is useful in several ways. They ensure strong joints. Square bars are reliable.

· Angle Bar

An angle stainless steel bar is shaped like the letter L. Each leg is 25 mm wide. These are bars used in shelves. The tensile strength of the material is 220MPa. Angle bars are durable.

This bar supports large loads. They are rust-resistant. A typical example is the AISI 316 grade. They are fairly simple to install. Essentially, this bar is very important in constructions. They provide stability. Angle bars are essential.

· Channel Bar

The stainless steel bar is U-shaped and is 30mm in depth. They are used in beams. This bar is very tough but it is not flexible at all. For channel bars, the yield strength is 230MPa.

It can be categorized under structural frames. They resist corrosion. The stainless steel used is AISI 304 grade. This bar is versatile. They can support large loads of weight. Channel bars are crucial. They are used widely.

· Tee Bar

A tee stainless steel bar has cross sectional area in the form of T, measuring 40mm across the top. They are used in reinforcements. This bar is sturdy. Tee bars have a tensile strength of 250 MPa. They resist rust. This bar is made of AISI 316 steel. They provide support.

Tee bars are also easy to install. They become part of different systems. This bar is essential. They are reliable.

· Hollow Bar

In the middle of the stainless steel bar, there is a hole. It has a diameter of 50 mm. Some of them are used in pipelines. This bar is lightweight. These hollow bars come with yield strength of 200 MPa. They are part of hydraulic systems. The AISI 304 grade is used.

This bar resists corrosion. It is easy to weld them. Hollow bars are versatile. They are employed in a wide variety of applications. This bar is important.

How Does the Grade of Stainless Steel Affect Its Performance?

Each grade is special. This makes the metal strong. There are some grades that do not rust. That is why they are good for different things. Let’s see!

· 304

This type is quite resistant to rusting. They have 18% Chromium and 8% Nickel. They are suitable for use in cold regions of the world. The stainless steel bar has a working temperature of up to 870°C. 304 is also non-magnetic. They are ideal for kitchen things.

This bar can be used anywhere. It also stays shiny. It is effective and has a longer duration. It can be conveniently sliced or shaped in the manner that is needed. Use 304 in many tools and products.

· 316

It carries more nickel than the 304. They also include molybdenum for more strength. Stainless steel bar also has good chemical resistance. It can also resist heat as high as 925°C.

It should be used in boats and pools. This type is also non magnetic. It remains clean and well maintained. However, one must clarify that they perform their function in saltwater environments as well. They are also used in food factories.

This bar is more durable in those difficult regions. It is used in the manufacture of medical equipment.

· 303

This type has sulfur. Because of this, they are easy to cut. The stainless steel bar contains 18% of chromium in its composition. This type does not readily rust. It can also resist heat temperatures as high as 750°C. It is also non-magnetic. They use it in screws and bolts.

This bar is strong and shiny. It has the advantage that the material can be bent quite easily. It is good for gears. They are also suitable for fittings. This type is durable and the surface is shiny.

· 410

They are brittle and hard. This bar contains 12% of chromium. It can bear up to 650°C. Magnetic, this is a stainless steel bar. They use it in knives. This bar is also good for pumps.

It has relatively good levels of resistance to wear and tear. They are not very shiny. For example, you can easily slice it. This type is convenient for tools. They also use it in valves. It remains longer when exposed to tough conditions.

· 420

They are good for making blades. This type has 12% of chromium. When influenced by the magnet, the stainless steel bar is found out to be magnetic. They can take temperatures up to 700°C. It’s strong and hard. This type is particularly useful when it comes to surgical instruments.

They are also used in scissors. This bar stays sharp. They resist wear well. It is useful for cutting tools. They also make cutlery from it. This bar is strong and wears a smooth surface.

· 17-4PH

This type is quite robust. It has 17% chromium. This particular material; the stainless steel bar can resist up to a temperature of 760°C. They are also magnetic. They used it in aircraft parts.

This bar is suitable for valves. They resist rust well in high stress areas. They also use it in turbines. This type is long-lasting. They are also used in gears. This bar does not bend when force is applied to it.

· Duplex

They are very tough. This type has got chromium of 22%. The material of stainless steel bar can withstand up to 300°C. They are also magnetic. It is rather a good product in the aspect of non-ability to rust. This is utilized in oil rigs. This bar is good for bridges. They resist cracking well.

It’s good for pipelines. They are also used in tanks. This type is long-lasting. They continue to be established in unfavorable areas. Stress is well managed in this bar.

| Grade | Composition | Corrosion Resistance | Strength (MPa) | Hardness (HRC) | Weldability | Cost |

| 304 | Fe, 18-20% Cr, 8-10.5% Ni | Excellent | 520 | 70 | Excellent | Moderate |

| 316 | Fe, 16-18% Cr, 10-14% Ni, 2-3% Mo | Superior | 550 | 75 | Excellent | High |

| 303 | Fe, 17-19% Cr, 8-10% Ni, S | Good | 480 | 68 | Fair | Moderate |

| 410 | Fe, 11.5-13.5% Cr | Fair | 440 | 50 | Poor | Low |

| 420 | Fe, 12-14% Cr, C | Fair | 500 | 55 | Poor | Low |

| 17-4PH | Fe, 15-17.5% Cr, 3-5% Ni, Cu | Excellent | 1000 | 40 | Good | High |

| Duplex | Fe, 22-26% Cr, 5-7% Ni, 0.1-0.3% N | Excellent | 620 | 30 | Good | High |

Table on How the Grade of Stainless Steel affects Its Performance!

What Are the Key Mechanical Properties to Consider?

These bars are tough. They bend but don’t break. This makes them suitable for use in buildings. Let’s find out what it is that makes them so powerful.

· Tensile Strength

The bar which is made of stainless steel is very strong. It can withstand large loads. This makes it useful. The bar’s σ_tensile is 520. It has a strength that is backed by ASTM tests.

The abbreviation UTS stands for Ultimate Tensile Strength, this means that the material will not easily fracture. We see it in bridges. They use it in bridges. The tensile strength shows that we can pull the bar to pieces.

· Hardness

A stainless steel bar is stubborn. It resists scratches. The HRC (Hardness Rockwell Scale) value is 88. They use a tester to check it. This makes it last longer. Durability means it cannot be easily flattened or crushed. That is why engineers prefer hard bars for buildings.

· Ductility

Another function is that a stainless steel bar performs well in bending. It won’t snap. The %EL (Elongation Percentage) is 40. This is done with machines. It is tested with machines.

They show how useful the bar is. In many cases, it is large. Ductile bars can be bent in any shape that is desired.

· Yield Strength

The yield strength is also good for a stainless steel bar. It appears when the bar begins to flex.

The σ_yield is 310. ASTM tests confirm it. They ensure that the bar is reliable. Yield strength helps bars to carry heavy loads. This is particularly important for buildings.

· Toughness

A stainless steel bar is dense. It resists hits. It has a CVN (Charpy V-Notch) value of up to 100.

Tests prove its toughness. They use hard bar in construction. This makes buildings safer. Durability is the ability of the bar to endure difficult situations.

· Elasticity

One of the important properties of stainless steel bar is that of elasticity. It undergoes deformation when force is applied and regains its original shape once the force is removed.

The E (Modulus of Elasticity) is 200 GPa. They compare it with machines. Elastic bar is useful for flexible structure. This makes them durable.

What Are the Dimensional Tolerances for Stainless Steel Bars?

Size is crucial here. Every bar has to be perfect. Now let us know how they quantify them.

· Length Tolerance

The stainless steel bar is also long. The allowable variation in length is 2mm. This means that the length of the bar could be slightly larger or slightly smaller.

The length is also determined with the help of CNC machines. ASTM standards make sure that it is right. They look at the length of the bar. Others ask engineers to check whether it is correct using tools. This length has to be exact. Bars have to be of optimum length for them to operate as they should.

· Width Tolerance

A stainless steel bar has a width tolerance of 1.5 mm. This means that the width of the bar can be a little off. Laser tools are used to measure the width. It helps the bar sit tight. ASME standards ensure accuracy. Engineers check the width. CNC machines cut it right.

This makes the bar useful. They expect the bar to be of a certain width. Engineers use special tools. The width of this bar is significant.

· Thickness Tolerance

Thickness tolerance of the stainless steel bar is 0.5 mm therefore; the thickness of the bar may vary slightly in its thickness. Thickness is gauged by CNC mills. ISO standards make sure that it is the right one that is used. This is done by engineers by using Micrometers to measure thickness.

This assures the bar to fit properly. They use these tools to determine whether it is correct or not. Engineers need exact thickness. It helps the bar to operate efficiently. This tolerance is important.

· Diameter Tolerance

The diameter tolerance for the stainless steel bar is 0.2 mm which is to say the round part of the bar can be slightly off. CNC lathes have a feature of diameter measurement.

Engineers measure it with a caliper. According to DIN standards, it is right. This allows the bar to fit well. They demand that the bar should have the right dimensions. This makes the bar useful. Engineers use tools to confirm. The size of this bar is the diameter.

· Straightness

The stainless steel bar must be straight. It can’t bend more than 0.1mm. Straightness gauges are employed by engineers. This implies that the straight condition of the bar is confirmed. CNC machines keep it straight. EN standards assist in ensuring that it is right.

They look for bends. This makes the bar fit well. Laser is used by engineers to verify. The straightness of the bar is relevant. They want the bar to be straight. This helps the bar to work properly.

· Flatness

A stainless steel bar can only be flat. It can only vary by 0. The flatness is also determined using CNC machines to an accuracy of up to 05mm. Engineers use flatness testers. JIS standards ensure that it is right. This helps the bar to fit correctly. They check the flatness.

Engineers want the bar to be flat. It makes the bar functional. They then use special apparatus to verify if the answer is right or wrong. That this bar is flat is important.

· Squareness

The stainless steel bar has to be square. It can vary by 0.03mm. Engineers use square gauges. CNC tools are used to measure the squareness. ANSI standards guarantee that wherever it is to be used, it is right. This helps the bar to fit well. They check the corners.

In this case, engineers need the bar to be perpendicular. It makes the bar relevant. They use special tools to determine if it is correct or incorrect. Regarding this bar, its squareness is not arbitrary.

| Tolerance Type | Measurement Range | Tolerance (± mm) | Standard | Accuracy | Method |

| Length | 100-6000 mm | 0.5-2.0 mm | ASTM A484 | High | Linear Measurement |

| Width | 10-500 mm | 0.2-1.5 mm | ISO 286-2 | Medium | Vernier Calipers |

| Thickness | 1-100 mm | 0.1-0.8 mm | BS 970 | High | Micrometer |

| Diameter | 5-300 mm | 0.05-0.6 mm | DIN 1013 | Precision | Dial Gauge |

| Straightness | L ≤ 2000 mm | 0.3 mm/m | ASTM A484 | High | Straight Edge |

| Flatness | L ≤ 1000 mm | 0.1-0.5 mm | ISO 1101 | Medium | Surface Plate |

| Squareness | T ≤ 50 mm | 0.1-0.3 mm | EN 10278 | Precision | Try Square |

Table on What Are the Dimensional Tolerances for Stainless Steel Bars!

How Does Heat Treatment Affect Stainless Steel Bars?

Heat changes the metal. This makes it more rigid or more flexible. They use ovens for this. Now let’s understand how heat is beneficial to the bars.

· Annealing

They heat the stainless steel bar up to 1040°C. This makes it soft. It is cooled in air or water. Valves, shafts and pipes like this process. The annealing makes the bar strong.

The grain size becomes finer. The heat removes stress. This is useful in many occupations. It gets shiny and nice. The process applies special ovens. The bar is now set for work.

· Hardening

The stainless steel bar is heated to 1000°C. They cool it fast in the oil. This makes it very hard. This is what tools and blades require. They are made to last longer by the process of hardening.

It makes them strong and tough. Martensite forms in the bar. This assists in the process of cutting things. It employs the use of hot furnaces. It makes the bar really strong. This step is very crucial.

· Tempering

They heat the stainless steel bar again to 150°C. This makes it less brittle. Gears and springs employ this process. Tempering enables the bar to bend. It becomes stiffer and harder.

They use ovens to heat it. The metal becomes balanced. This step is good for many uses. It prevents formation of cracks and breaks. The process makes the bar dependable. This makes it ready for work.

· Stress Relieving

The stainless steel bar is heated to 480°C. This removes stress. Weldments and parts employ this. They become stable and strong. The bar cools gradually in air. This process stops bending.

It makes the bar last longer. Stress relieving involves using hot ovens. The metal becomes smooth. This step is useful in many ways. The bar prepares for difficult tasks. It is maintained in good condition.

· Quenching

They heat the stainless steel bar and then quench it quickly. This makes it hard. They use oil or water. This is what knives and tools require. The bar gets strong.

Quenching causes the formation of martensite in the metal. This step is very important. It assists in cutting and working. The process makes the bar stiff. It prepares for other jobs. The metal becomes very hard.

· Solution Treatment

The stainless steel bar is heated to 1000°C. This dissolves bad stuff. They cool it fast. Medical tools employ this process. It makes the bar smooth.

Solution treatment is beneficial in the many ways. The metal becomes stable. This step is actually critical. It prepares for challenging tasks. It employs special ovens in the process. The bar becomes very strong.

How to Determine the Right Size and Shape for Your Project?

This is important. It’s the size and shape that count. They use tools to quantify. Time for learning how to choose the right bar.

· Length

This is a stainless steel bar that is available in various standard lengths. You can measure with a caliper. This tool helps. Examples of such measures include 12, 24, 36 and so on.

T304 or T316 are types. Each has a use. Longer bars for CNC, mills and lathes. The tool needs precision. Length describes how it operates.

· Diameter

The diameter of the stainless steel bar must be measured with the help of a micrometer. It’s precise. Diameter like 5, 10 or 15 is essential. Use T304 or T316. This choice matters.

It is important for the round bars to come in different sizes. Each size is suitable for a given context. ASTM standards help.

· Width

Therefore, the width of the stainless steel bar bears some importance. It is measured through the aid of a caliper. This tool is accurate. Usual are width 2, width 4 or width 6.

The choices are T304 and T316. Each has different uses. Flat bars require more precision as far as the width of the bar is concerned. The right width produces the correct fit.

· Thickness

Thickness affects strength. With a micrometer, determine the diameter of the bar of stainless steel. It’s precise. Such numbers as 1, 2 or 3 are significant. Choose T304 or T316.

This choice matters. Bars of each type are of different thickness. Pick the right one. Specifications matter. For example, one might be 2. But it is the type that you select that defines how long it will last.

· Cross-Section

The cross-sectional shapes of the stainless steel bar differ. Thus, whether it is rectangular, square, or round, it meets various requirements. Cross-section influences strength.

Yes, subgrades like 303SS or 410SS do matter. Choose the right shape. Numbers such as 4, 5 or 6 are different.

· Weight

The weight of the steel is determined by the dimension of the bar as well as the type of steel which is used. Use formulas to calculate. It is expressed in grades like T304 or T316.

When measuring, make sure to use a scale so that you get the right dimensions. Weight varies. This means that a bar might weigh 15 or 25.

· Surface Area

Calculate with formulas. It is affected by different types of finish such as 2B or BA. Check whether the thickness of the stainless steel bar has been appropriately measured.

The area of the surface varies according to the shape of the figure. A bar might have 20 or 30. Finishing depends on this.

· Load Capacity

Load capacity is vital. Calculate with formulas. Measure dimensions accurately. The load capacity depends on the grade such as T304 or T316. Each supports different weights.

Consequently, a stainless steel bar might contain 50 or 100. ASTM standards ensure quality.

· Application Fit

Fit is important. Measure dimensions accurately. Fits are grade specific such as 303SS or 410SS. The stainless steel bar is for CNC machines or mills. Specifications vary. For instance, it may be 3 or 5. Proper fitting is one that is gotten through correct measurements.

What Are the Key Differences Between Cold-Finished and Hot-Finished Bars?

They look different. This alters their mode of operation. Some are stronger. Now it is time to determine what distinguishes these two types.

· Surface Finish

The stainless steel bar is extremely polished. AISI 304 grade looks polished. The surface roughness is Ra 0.8. This makes it easy to clean. ASTM standards provide direction.

Intensive makes it bright drawing keeps it shiny. There are bars that are brushed. Hot finishing may reveal the presence of mill scale. It impacts the look. Bright annealing makes it shinier. Electro-polishing makes it glossy.

· Dimensional Accuracy

A bar made of stainless steel is very accurate. Cold finish bars are within ± 0.002. This helps engineers. They use precision rolling. Hot-finished bars are of wider sizes. ASTM standards set limits. Cold finishing also contributes to making the thickness of the material uniform.

It is also important in parts. CNC machining likes accuracy. Dimensional stability matters. Sizes vary depending on the function it will be used for.

· Strength

This is a very strong bar made of stainless steel. AISI 316 bars have a tensile strength of 550 MPa. Cold-finished bars are stronger. ASTM standards maintain it high. Quenching boosts strength. Martensitic grades are stronger. Solution annealing helps.

Nickel makes it durable. Strength changes by grade. Applications need strong bars. 800 MPa strength is present in some bars. They use hardening for strength.

· Hardness

The material used for making the stainless steel bar is hard. It has a Rockwell hardness of between HRC 20-25. Cold-finished bars are harder. ASTM keeps it steady. Cold working makes it more difficult. Solution treatment affects hardness. Tempering makes it harder.

Hardness means wear resistance. Applications need hard bars. Composition changes hardness. Cold drawn bars are very hard. This process makes them tough. Hard bars last longer.

· Grain Structure

Stainless steel bar belongs to fine grained material. Cold finishing produces fine grains. This changes properties. ASTM standards define grain size. Coarse grains imply little and weak bars.

Hot-finished bars are characterized by large-grained structures. Annealing changes grain structure. Different processes change grains. It also concluded that fine grains are useful in fatigue tests. For instance, the grains of duplex grades are special. Treatments affect grain size in different ways. In machining, fine grains are preferable.

· Processing Cost

It is evident that the price of the stainless steel bar is cheaper when it is hot finished. Cold finishing adds steps. This raises costs. Hot processes require less energy compared to cold processes. Annealing costs more. Different grades change costs.

Quenching and tempering are expensive. Surface treatments cost extra. High precision costs more. Mass production saves money. Every bar type has its own price. ASTM standards make it efficient. Efficient processes cut costs.

· Yield Strength

An example of a material that exhibits high yield strength is shown in the figure below; it is a bar made of stainless steel. AISI 304 bars possess the yielding capacity of up to 215 MPa.

Cold-finished bars are over 250 MPa. Yield strength resists bending. ASTM keeps it steady. Alloying elements help. Heat treatment increases the yield strength.

The given grades are not the same in terms of their ability or strength. Applications need strong bars. It becomes stronger through precipitation hardening. Duplex grades yield higher.

· Tolerances

The stainless steel bar is closely toleranced. Cold-finished bars are within ±0.001. This means a better fit. ASTM sets tolerances. Tight fits are more useful in engineering.

CNC machining requires this level of accuracy. Hot-finished bars are wider. Cold finishing improves consistency. In parts it is the tightness of the tolerances which are so important.

Each grade has standards. Repeatability of the tolerances means consistent bars. Tolerances matter a lot.

How Does Welding Affect Stainless Steel Bars?

Heat from welding alters the bar. This can make it bend. They have to maintain it. We shall see the outcome when they weld the bars.

· Heat Affected Zone

Welding alters the physical state of a metal bar. Heat affects HAZ. It can make parts very hard like the 200 HV. At 950°C, metals shift. Tiny grains grow. Joints get cracks.

GTAW welding helps. Chromium and nickel mix. Expansion makes stress. The bar changes shape. HAZ needs checking. Heat alters it. Heating helps fix bars.

· Distortion

Welding bends bars. Heat makes them twist. This bending is distortion. Heat changes size. Thermal expansion matters. Joints get off. Preheating stops bending.

TIG welding will cool the bars. Bars shrink when cold. Metals cause more bends. Fixtures help. Uneven heat bends bars. Relief fixes stress. Short arcs help. Low heat stops bends.

· Corrosion Resistance

Welding rusts metal. Heat changes oxide layers. It can rust. Chromium moves. HAZ rusts more. Cleaning is key. Passivation protects. ER308L filler helps. Chlorides rust welds.

Low heat stops rust. Pitting can happen. Surface affects rust. Polishing welds help. Inert gas helps too.

· Strength Reduction

Welding weakens metal. Heat lowers strength. This makes bars weak. Yield strength reduces in HAZ. Structure changes to brittle. Using 316L helps. High heat weakens more.

Preheating helps. Post-weld fixes the strength. Niobium alloys add strength. Technique matters. Stress at welds forms.

· Microstructure

Welding changes metal inside. Heat alters grain. This changes bars. Austenite forms in HAZ. Cooling affects phases. More ferrite can form. Dendrites grow. Duplex stainless steel helps.

Heating fixes grains. Metallography shows inside. Nitrogen helps stable bars. Seams need checking. Segregation happens. Thermal changes parts.

· Weldability

The welding of metal bars is not very easy. Heat affects welds. This takes skill. Using 304L helps. Low heat is best. Heating stops cracks. Right filler is key. GTAW controls heat. Gas keeps bars clean. Joints must be clean. Heat control matters. Speed affects welds.

How to Evaluate the Quality of Stainless Steel Bars?

This goes a long way in ensuring that the quality of the stainless steel bars is good. They look for scratches. This requires checking them well. Okay, let me show you how they do it.

· Visual Inspection

Examine the surface carefully for any imperfections. It should look shiny. Scratches can be associated with low quality products. The straightness has to be ensured.

Thus, rust spots can let you know that the bar is not good. There should be no cracks on this bar. Check it under light. It helps to see small defects. Uniform color is important. Use a magnifying glass.

· Ultrasonic Testing

Ultrasonic waves scan the interior of the bar. This test employs a transducer. It sends sound waves. Waves bounce back. Check for flaws inside. Loud signals can be problems.

High frequency sound is useful in problem identification. This test is fast. It’s very accurate. In good bars there should be clear signals. Use a display monitor.

· Magnetic Particle Testing

Magnetic fields reveal flaws. It shows tiny cracks. Apply iron powder. This powder tends to adhere to defects. Use a magnet. It makes the field. Look for patterns. Flaws appear as lines.

This bar needs to be clean first. It’s very detailed. Use a UV light. It helps see better.

· Hardness Testing

Press a diamond tip. It makes an indent. Check the size. Smaller is harder. Use a Rockwell tester. It shows numbers. The bar needs even hardness. Different spots must match.

Consistent hardness is key. This test is simple. It helps compare bars. Use a dial gauge.

· Chemical Analysis

Test for elements. Use a spectrometer. It shows what’s inside. The bar requires specific metals. No extra elements allowed. Look for chromium, nickel.

Every part must conform to requirements. This test is exact. It’s fast and detailed. Check every batch. Good bars pass. Use chemical reagents.

· Tensile Testing

Swing this bar until it snaps. Check the force. It shows strength. Use a tensile tester. It measures elongation. The bar requires high tensile strength. Weak bars can break fast. This test is crucial. It ensures durability. Use a load cell. Watch the display.

Conclusion

When selecting the best stainless steel bar, one should look at the ASTM specification, tensile strength and the AISI grades. Visit ALLOYXPERT for more information. Choose the right bar for yourself today.