Despite not being the first item you may deem a crucial boiler component, boiler tubes are vital. Long and cylindrical, these tubes are in charge of transporting hot water, steam or industrial fluids. They move steam from the heat source to the components of the system that need it.

Boiler tubes are necessary for industrial boilers. They are essential to boiler efficiency and safety. Steam boilers, power plants, and other sectors use boiler tubes. High-quality, durable boiler tubes ensure plant efficiency. Boiler tubes can be medium or high-pressure.

It’s essential to buy a company boiler that meets industry standards. This equipment must also be durable. You don’t want to buy the wrong boiler tube and pay more to fix it than you planned. So, stay fixed on this page to discover what you must know before buying boiler tubes.

Key Highlights!

- Boiler tubes play a crucial role in transporting hot water or steam. It ensures efficient heat transfer in industrial boilers, power plants, and other sectors.

- Consider critical factors when choosing boiler tubes. It includes dimensions, tensile and yield strength, hardness, thermal conductivity and expansion, pressure ratings, and adherence to industry standards.

- You have various options for sourcing boiler tubes. The most recommended option is buying directly from the manufacturer.

- Choose Alloyxpert for premium quality boiler tubes made from superior steel alloys. The company has a proven track record of delivering durable boiler tubes.

How Are Boiler Tubes Classified Based on Their Application?

Different types of boiler tubes are used in various boiler systems. Each type is designed to handle specific fuel sources and operational needs.

1) Oil and Gas Boiler Tubes

Oil and gas boilers are primarily used in residential and commercial buildings. However, we can also find them in some industrial applications. The tubes in these boilers are typically made of carbon steel or stainless steel. It depends on the specific fuel type and operating conditions. These tubes have unique designs to transfer heat efficiently.

You must consider below factors when purchasing oil and gas boiler tubes

- Dimensions

- Thermal conductivity and expansion

- Compliance with industry standards

- Overall cost

Besides, you must look for the below industry standards.

| Category | Standard | Explanation |

| ASME (American Society of Mechanical Engineers) Standards | ASME SA-213/SA-213M

|

This standard covers the requirements for seamless steel tubes used in boilers, superheaters, and heat exchangers.

|

| ASME SA-335/SA-335M

|

This standard specifies the requirements for seamless steel pipes made from ferritic alloy steels.

|

|

| ASME Section I

|

This section of the ASME Boiler and Pressure Vessel Code contains rules and requirements for the construction of power boilers.

|

|

| ASTM (American Society for Testing and Materials) Standards | ASTM A213/A213M

|

This standard covers seamless steel tubes made from ferritic and austenitic alloy steels for use in boilers, superheaters, and heat exchangers.

|

| ASTM A335/A335M

|

This standard specifies requirements for seamless ferritic alloy steel pipes designed for high-temperature service.

|

|

| EN (European Norm) Standards | EN 10216-2

|

This standard covers the technical delivery conditions for seamless steel tubes made from non-alloy and alloy steels with specified elevated temperature properties.

|

| EN 10217-2

|

This standard specifies the technical delivery conditions for electric welded (not seamless) steel tubes made from non-alloy and alloy steels with specified elevated temperature properties.

|

Let’s consider a case study.

The building had a boiler made of carbon steel tubes. Over time, these tubes experienced corrosion, likely due to natural gas combustion. The building took over a retrofit. In this project, the engineers focused on the boiler. The corroded carbon steel tubes were replaced with higher-grade stainless steel tubes. They used ASTM A213 to ensure the new stainless steel boiler tubes meet the necessary specifications.

2) Biomass Boiler Tubes

These boilers burn organic materials to generate heat. It can be wood chips, pellets, or agricultural waste. The tubes in these boilers are often made of high-temperature alloys. Thus, they can withstand the corrosive and erosive nature of biomass combustion. The tubes may also have special coatings or designs to improve heat transfer.

3) Coal-fired Boiler Tubes

These boilers are commonly used in power plants and large industrial areas. The tubes in these boilers are typically made of high-temperature alloys. It can be stainless steel or nickel-based alloys. These materials help withstand the high temperatures and corrosive environment of coal combustion. These tubes may have specific designs, such as fin or rifled tubes.

4) Circulating Fluidized Bed Boiler Tubes

CFB boilers are designed to burn a wide range of fuels. It includes coal, biomass, and waste materials. The tubes in these boilers are exposed to a highly abrasive environment due to the circulating bed of solid particles. Thus, they are made of wear-resistant materials, such as high-chromium alloys or ceramics.

5) Thermal Oil Boiler Tubes

These boilers operate a heat transfer fluid, typically a synthetic oil. It is then circulated to various processes or equipment. These tubes may be made of carbon steel or stainless steel. Of course, it depends on the operating temperatures and the specific thermal oil used.

What Are Different Types of Boiler Tubes Based on the Material?

You can choose from a variety of boiler tubes. There are carbon steel, alloy, and stainless steel boiler tubes. There are different grades and subcategories for each of these types of materials. They offer various levels of efficiency and properties. However, your choice will depend on the specific application. Below is a review of the various types of boiler tubes:

1) Carbon Steel Tubes

The fact that these boiler tubes are a cheaper option and durable leads to their popularity. Applications where corrosion resistance is not a priority also suit it.

Carbon steel is made from iron and carbon, which are strong and malleable. It is appropriate for most uses. Yet, it may not be suited for corrosive or exceptionally high temperatures. This is so even though it is capable of withstanding high temperatures.

Carbon Steel tubes have significant strength and endurance. They may suit boiler systems that operate at low pressure and temperature. So, you must remember that carbon steel tubes are prone to corrosion. This is particularly true for settings with a high acid or moisture concentration.

2) Alloy Steel Tubes

It would be fair to say that alloy steel tubes are the heroes of boiler tubes. They are superior because they are robust and tough. Besides, they can handle high temperatures better and are more durable.

They contain alloys consisting of components like chromium and nickel. These components improve their performance and lifetime in harsh boiler conditions.

Alloy steel tubes are best for high-pressure boilers. They are a good choice if you work in hot temperatures. In applications that need corrosion resistance, they perform admirably.

Hence, they are perfect for high-pressure uses that carbon steel tubes cannot handle. Note that they are also expensive. So, it is all about striking the correct mix for your respective requirements.

3) Stainless Steel Tubes

These corrosion-resistant boiler tubes are exceptional. They withstand corrosion more than other materials. So, they are ideal for harsh or corrosive situations. Some examples of such conditions are chemical plants, refineries, and maritime applications.

Additionally, stainless steel tubes have good heat transmission capabilities. They can sustain high temperatures and pressures. They suit fire-tube and water-tube boilers.

Beware that stainless steel boiler tubes are expensive. They may cost more than carbon or alloy steel. Choosing the proper stainless steel grade depends on several factors. These are the boiler’s operational temperatures, pressures, and corrosion.

| Material Type | Key Properties | Typical Applications | Cost |

| Carbon Steel Tubes | 1) Affordable

2) Good strength & ductility at moderate temperatures 3) Moderate corrosion resistance |

1) Low-pressure boilers

2) Hot water heaters 3) Low-temperature process applications |

Low |

| Alloy Steel Tubes | 1) High strength & creep resistance at elevated temperatures

2) Improved corrosion resistance compared to carbon steel |

1) High-pressure boilers

2) Super heater and re-heater applications 3) Chemical plants |

Medium |

| Stainless Steel Tubes | 1) Excellent corrosion resistance

2) Good heat transfer properties 3) High strength at elevated temperatures |

1) Power plants

2) Marine boilers 3) Chemical processing plants 4) Food & beverage industry |

High |

Top 10 Factors to Consider Before Buying Boiler Tubes

You must consider numerous variables before buying boiler tubes. Here are the crucial tips to consider:

1) Dimensions – Diameter, thickness, and length

The diameter, thickness, and length of boiler tubes are crucial. Pay attention because they vary in size, wall thickness, and height. Choosing the suitable proportions for your boiler system is vital.

Consider the particular design and requirements of the system. It is possible that incorrect dimensions will result in poor heat transfer. Also, it could cause structural problems or compatibility issues.

Boiler tubes with bigger diameters are used in water-tube boilers. Smaller diameters are better for fire-tube boilers. Also, the tube’s wall thickness should withstand internal operational forces. Ensure that the tubes perfectly match your boiler system. Otherwise, they will not function accordingly.

Boiler tubes come in many sizes. So, you must specify the precise dimensions that you need. Check your dimensions twice to ensure that you don’t make any mistakes.

2) Tensile Strength

It refers to the tube’s capacity to resist the forces attempting to rip it apart. Boiler tubes can handle heavier weights with higher tensile strength. Also, tubes with enough tensile strength can endure internal pressures during operation.

High tensile strength is also essential for applications requiring many thermal cycles. If you have a high-pressure boiler system, you should pick tubes that can handle more tension. Think about how much stress and pressure your boiler can handle. Then, pick tubes that have the proper tensile strength.

For boiler tubes, tensile strength keeps the tubes from breaking. Breakage can occur because of too much internal pressure or heat stress. If the tensile strength isn’t met, terrible things can happen. It may lead to tubes leaking or breaking. In some cases, the whole boiler system may stop working. It can endanger workers and cost a lot of money in repairs and downtime.

3) Yield Strength

Consider material yield strength when choosing boiler tubes. It determines if the material can resist stress without deforming. Ultimately, yield strength is a crucial factor. It plays a significant role in guaranteeing safety. Also, it ensures dependable operation under high pressure and temperature.

During the boiler operations, the tubes are subjected to various stresses. These include thermal stresses, internal pressure, and external loads. Boiler tubes are essential since they work at elevated temperatures. Hence, they can impact on the material’s mechanical properties. So, the yield strength of boiler tubes is very crucial.

The tube’s yield strength determines its highest stress level before deformation. If stress exceeds yield strength, tubes can permanently distort. It would compromise the tubes’ structural integrity. It might result in leaks, fissures, or even catastrophic failure.

Metals, in general, have a drop in yield strength as the temperature increases. That makes them more prone to deformation over time. Selecting a material with high yield strength at projected operating temperatures is crucial. It makes sure tubes can resist regular and transient stresses.

4) Hardness

It is worth considering the material’s hardness when choosing boiler tubes. The hardness measures how easily a rigid material can pierce the tube. Under different operating situations, it affects the material’s resistance to wear. In the context of boiler tubes, hardness plays a crucial role. It checks how well the tubes can handle specific stresses and wear from impact or friction.

Boiler tube hardness depends on probable erosion, wear, or localized deformation. The working conditions determine this. For instance, high-velocity boiler tubes with high flow may need rigid materials. It is to ensure adequate erosion resistance.

Additionally, balance the need for hardness and other material properties. Ductility and toughness, for example. The boiler tubes can have adequate resistance to brittle fracture through this process.

Also, it ensures that it can withstand thermal stresses without shattering. Thus, selecting tubes with a suitable hardness for your application is essential. By doing so, you can avoid damage and extend your lifespan.

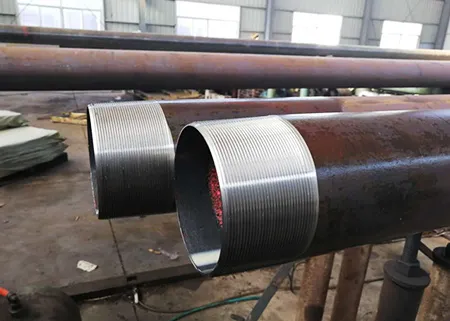

5) Pipeline Connection Method

The connection method of the boiler tubes is crucial for ensuring proper installation. It allows for leak-proof connections and ease of maintenance. You must consider the following connection methods and choose a suitable one. Consulting a qualified engineer can help you select the optimal connection type for your boiler system.

Welding: Welded connections provide strong and leak-tight joints. However, they require skilled welders and appropriate welding equipment. This method is often preferred for high-pressure and high-temperature applications.

Threaded Connections: Threaded connections are simple and allow for disassembly and reassembly when necessary. However, they may exhibit potential leakage issues. Thus, they may not be suitable for high-pressure or high-temperature applications.

Compression Fittings: Compression fittings use a ferrule or compression ring to create a leak-tight seal. They offer a reliable and easy-to-install option for specific applications.

Flange Connections: Flanged connections involve bolting flanges together with gaskets. It allows for easy disassembly and maintenance. Such connections are commonly found in high-pressure and high-temperature applications. However, this connection method is more expensive than other methods.

6) Anti-Corrosion Protection

Will your boiler tubes be exposed to harsh environments? Do you want to install them in areas with high humidity, chemical contaminants, or extreme temperatures? These factors can lead to corrosion and reduced service life of the boiler system. Thus, implementing anti-corrosion measures is essential. Here are some standard anti-corrosion protection techniques used for boiler tubes:

Coatings: Ensure the tube manufacturer applies protective coatings. They come in various forms, such as paints, enamels, or specialized coatings. It can create a barrier against corrosive elements and extend the lifespan of the boiler tubes.

Galvanizing: Galvanizing involves coating the boiler tubes with a layer of zinc. It shields the underlying metal from corrosion. This method is a popular choice for applications involving moisture and salt exposure.

Cathodic Protection: Cathodic protection systems can prevent corrosion by supplying an external electrical current to the boiler tube. It is a less preferred corrosion protection method.

Corrosion-Resistant Materials: Use boiler tubes made from corrosion-resistant materials like stainless steel or advanced alloys. While more expensive, these materials can increase the system’s service life.

7) Thermal Conductivity and Expansion

In boiler operations, efficient heat transfer is necessary. Heat must be properly transferred from the combustion gases to the water or steam. Boiler tubes need to have a high thermal conductivity to do this. Materials with higher thermal conductivity allow for a more efficient movement of heat. It improves boiler performance and increases energy efficiency.

The thermal conductivity depicts how the temperatures spread inside the boiler tubes. Poor heat transmission materials cause a more significant temperature difference inside and outside tubes. It can lead to higher thermal stresses and an increased risk of failure due to fatigue.

Starting up, shutting down, and changing loads can cause boiler tube thermal cycling. You can prevent thermal fatigue and cracking using higher thermal conductivity materials. These materials can effectively distribute and release thermal loads.

Thermal expansion is another vital aspect to consider when choosing boiler tubes. Different temperatures affect tube strength and dimension stability. Thermal expansion can occur due to significant temperature changes during operation. Not properly accounting for thermal expansion can be stressful. It may create high thermal stresses in tubes, causing deformation, breaking, or failure.

8) Pressure Ratings

It entails the highest pressure tubes can safely handle during operations. The tubes inside a boiler are made to handle the pressure that the water or steam inside them creates. They can also stand up to any pressure from the gases of burning or the air around them. The working pressure of the boiler system directly affects the tubes’ pressure rating.

When choosing boiler tubes, consider the highest pressure the boiler will encounter. Also, consider any temporary or unusual changes in pressure that might happen.

The tubes’ pressure number should provide enough safety margin to handle these situations. It also considers any wear and tear over the expected working life. Choosing well is crucial, so the boiler system works safely and reliably.

9) Standards and Certifications

Boiler tubes must meet industry standards to ensure quality, safety, and performance. Check for tubes approved by well-known groups like the British Standards Institution (BSI). Also, look out for the American Society of Mechanical Engineers (ASME) specification.

With these certificates, you can be sure that the tubes have been through a lot of testing. It also figures out how they meet the requirements for the use they are meant for. It also determines that the tubes meet standards for quality and safety.

10) Cost Considerations

Lastly, think about your cash! You should weigh the price against the quality and features you need. Know that cheaper choices may not always be the best over time. Factors other than price should matter. You should find a balance between quality and price.

Look at the overall cost of owning the tube. It includes purchase, installation, and lifetime maintenance costs. Buying pricier tubes may save money over time. They endure longer and need less maintenance.

What Are Different Channels for Sourcing Boiler Tubes?

You can source boiler tubes from various channels. These include sourcing from manufacturers and online marketplaces. Get more information about this below:

1) Directly from manufacturers

You can buy boiler tubes directly from genuine manufacturers like Alloyxpert. Usually, manufacturers can make the tubes fit your needs. They can also offer technical help and advice. Additionally, buying from the manufacturer can save money. Direct purchases eliminate mediators.

Remember that not all manufacturers accept small orders. Also, they may not work with one-time customers. In this case, working with a distributor or supplier might be better.

2) Through distributors and suppliers

These middlemen help companies get their goods to people who want to buy them. They offer various boiler tubes from different manufacturers. Sometimes, the prices are usually fair. These suppliers typically have long-term partnerships with several manufacturers. Hence, the latter allows them to get and stock different products.

You may benefit from working with a respected distributor or supplier. They can help you choose the suitable boiler tubes for your needs. Also, distributors can provide extra services. These comprise custom cutting, packaging, or organizing supplies. Suppliers with experience know a lot about boiler tube specifications and standards.

3) Online marketplaces

In the digital age, you can buy boiler tubes online. With different sites, you can look at products from various sellers and compare them. They usually provide necessary product information, like prices and specs.

You can learn about and compare different boiler tube choices. Also, you can receive quotations from various sources via online marketplaces. However, buying from online sources requires caution. Product quality and industry standards can be hard to determine.

When looking for an online marketplace, find one that vets their suppliers. Consider those that provide buyer protections like return or warranty policies. Such provisions will come to the rescue if you receive low-quality supplies.

How to Choose the Right Supplier for Boiler Tubes?

The right boiler tube supplier is essential for plant safety and efficiency. There are some factors to consider when choosing a boiler tube manufacturer. These include experience, reputation, and quality control methods. The following list covers this extensively:

1) Reputation and experience in the industry

It’s important to remember how important it is to find the right boiler for your business. A supposedly trustworthy company should have a history of making good tubes. Also, a reliable supplier should have good experience.

Find out if they have a history of delivering high-quality tubes. It implies that their supplies have to meet the standards set by the business. For online marketplaces, you can check previous customer reviews.

A good boiler provider will offer everything you need to fix your boiler system. It will help you figure out problems you know about and ones you don’t. Don’t forget how important it is to choose well-known names. Make sure they can meet your needs now and in the future.

2) Ability to provide specific boiler tube types and quantities

Suppliers need to be able to provide particular boiler tube types and quantities. So before choosing a supplier, ensure they meet types and quantity requirements. Some suppliers may only sell specific boiler tubes. At the same time, others may have a more comprehensive selection. Whether you require regular or custom tubes, you need a reliable seller.

Their supplies must be of good quality. That’s because they work in high temperatures and pressures, which can wear them down over time. You need to find a company that sells high-quality boiler tubes in different sizes. It ensures that your heating system works well and safely.

3) Competitive pricing and clear cost breakdowns

When buying boiler tubes, you don’t need to spend much money. A good boiler tube supplier should offer cheap choices. Yet, they must not skimp on quality or durability. Find out how the supplier sets prices. Make sure that their cost breakdowns are clear.

You should ask for thorough quotes that include costs, such as shipping, taxes, and any other fees. Also, you can compare what different suppliers offer. Hence, you can make smart choices with transparent prices.

Knowing all the costs of running a boiler is the best way to get the most out of your investment year after year. To choose an efficient boiler, consider its capacity, pressure, and temperature. Since cost and performance go hand in hand, pay close attention to this particular factor.

If you buy a cheap tube that isn’t very good, you might have to pay more for fixes in the long run. Even worse, you might have to get a new boiler sooner than expected.

4) Timely delivery and logistics management

When choosing the right boiler tube provider, timely delivery is crucial. The same goes for logistics management. Any delay or mistake in shipping can cause expensive downtime and production losses.

A dependable supplier should have a sound logistics system in place. Doing so ensures that boiler tubes get to the customer quickly. It means having a solid transport system. It also entails using the proper packing to prevent damage during shipping.

It may also include real-time tracking to monitor the package in transit. Coordinating with the customer to ensure smooth delivery is also applicable. Having maintenance schedules is also an essential part of good logistics management.

This teamwork helps keep problems to a minimum. It allows for seamless integration of the new boiler tubes into the existing system. Additionally, a trustworthy provider should have backup plans. These can come in handy for unplanned events that may arise.

5) Customer service and technical support

A good supplier should have excellent customer support from the beginning to the end. Checking their customer support provisions should top your list. The support team should respond to questions promptly and give correct information. Whenever a need arises, you should be able to contact them for inquiries or sales issues.

To provide good customer service, they must have knowledgeable staff. These people must be able to answer questions, give advice, and quickly fix problems. In this manner, you can easily build trust, making working with them easy.

If you prioritize customer support, consider the availability of 24/7 support. Also, check out the support channels. Check if there are provisions for email or phone support. Some online marketplaces provide a contact form for users.

Since boiler tubes are specialized parts, technical help is also critical. They need people who can choose materials, build, install, and maintain them. A trustworthy provider should have skilled engineers and technical experts. These people can provide helpful information and suggestions tailored to their needs.

These technical experts should have complete information about their products. They can help you figure out the right size and specifications. Also, they can tell you the best ways to install and maintain the boiler tubes. Their knowledge can help customers make wise choices. Consequently, it improves their boiler systems’ lifespan.

Final Thoughts!

Boiler tubes are an essential part of steam plants. Tube quality and longevity depend on the material and manufacturer. High-quality boiler tubes provide system safety, efficiency, and reliability. You can choose what suits you by carefully evaluating the variables in this guide. Most importantly, prudent selections save money over time.

Remember that buying the wrong boiler tubes can cause problems that cost a lot to fix. It can also cause downtime and even pose safety risks. Spend some time thinking about your choices, talk to professionals. Choose a trustworthy seller who can give you the help and advice you need. Also, consider their experience, reputation, and more. It gets you the appropriate boiler tubes that keep your system running smoothly.

They are also crucial for saving energy and lowering repair costs. Additionally, they make your equipment last longer. You can also have peace of mind from knowing that your boiler system is made with the best parts. Hence, you know their capacity to work reliably and efficiently for years.

If you need boiler tubes for industrial operations, look no further than Alloyxpert. We manufacture superior boiler tubes from premium steel alloys. Contact us today and let our experts guide you in selecting the perfect boiler tubes for your application.