Carbon steel is used as the foundation for many large and small projects. It’s in the skyscrapers that dominate our cityscapes and the wrench in your toolbox. However, these are only some of the features; there are others, such as strength and cost.

It can be scary if it’s your first time purchasing carbon steel. It is particularly valid for new clients. Do not be afraid! This thorough guide has the info. With it, you’ll judge and ensure your project is on time. If you have this guide, you’ll be ready to use carbon steel fully for your upcoming project!

Carbon Steel – Know the Basics!

The magic of carbon steel lies in its simplicity – it’s mostly iron, with a sprinkle of carbon (between 0.02% and 2.0%) mixed in. Its power lies in the exact ratio of these two elements. This simple formula makes a solid and valuable material.

More carbon makes the steel more robust and harder. But it also makes it less bendable. Less carbon makes steel more flexible and easier to work with. But, it has slightly lower strength. You must understand the link between carbon content and traits. It is vital when picking the correct steel for your project.

What Are the Applications of Carbon Steel?

Carbon steel is the ultimate chameleon. It is a preferred material for many industries. They like it because it can take on infinite shapes and forms.

1) Construction and Infrastructure

Imagine a world without steel. It’s virtually impossible! Carbon steel is essential for many constructions. It is in the famous skylines of cities and the strong support of bridges. It is affordable, robust, and recyclable.

Thus, it is excellent for building railroads, bridges, and other constructions. That’s because of these features. Carbon steel is strong and beautiful. The Eiffel Tower and also the Golden Gate Bridge, two famous structures, demonstrate this. They mainly rely on carbon steel for their frames.

2) Automotive and Transportation

The qualities of carbon steel can be tailored to fit specific needs. It is widely used in the frames and parts of vehicles, trucks, and motorcycles.

For example, companies use it for the strong frame of a truck or the bendable panels of a car. That makes it ideal for the automotive industry.

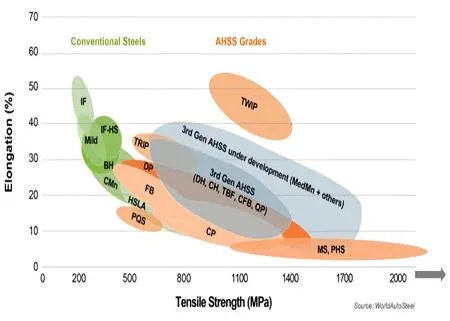

Modern automakers are constantly pushing the boundaries. They use AHSS to make lighter, stronger cars. It also enhances fuel efficiency and safety.

3) Manufacturing and Machinery

Imagine a factory floor free of steel. Carbon steel is used in many applications. These include heavy-duty machinery that makes many items and workshop tools.

It is tough. It can withstand wear and tear. That makes it suitable for machine components, tools, and many industrial uses. Regular household equipment uses carbon steel parts like fridges and washing machines. The material is tough and reliable.

4) Other Industries (Energy, Oil & Gas, etc.)

Carbon steel’s significance extends beyond these critical examples. So it is used a lot in the energy sector. It includes pipes and pipelines. It is also used in oil and gas exploration for drilling equipment. And it’s even used in everyday appliances. Carbon steel is adaptable. It allows for a wide range of steel’s uses. That makes it a prevalent material in the modern world.

How to Pick the Best Carbon Steel for Your Needs?

Are you prepared to use carbon steel to its fullest capacity for your upcoming endeavor? Let’s look at how to pick the best kind to suit your needs. Here are three crucial pointers to consider while buying carbon steel:

1) Application

High-stress applications, like bridge beams, need a high-strength grade. However, a smaller project could need weaker and more flexible steel—for example, a decorative railing. Understanding your project’s specific demands ensures that you choose steel. It will work well over its lifetime.

2) Skill Level

Specific carbon steel grades necessitate specialized welding procedures or equipment. Consider your experience. Select a steel that matches your skills. It will ensure a successful project. Remember, online resources and tutorials can give helpful info. They cover welding processes for different grades of carbon steel.

3) Budget

Carbon steel comes in various grades and coatings, which influence the price. Decide on your budget. Look for a steel that has the needed qualities and fits your budget. The lowest option may seem appealing. But remember that quality and service are also crucial. A diligent consumer should also weigh the long-term value. Pricier steel with higher durability may be a better long-term value.

Top 7 Factors You Should Consider When Purchasing Carbon Steel

You’ve picked the best type of carbon steel. We’ll discuss buying it in today’s fast-changing market.

1) Grade and Quality

It refers to a type of carbon steel. It is defined by industry standards such as ASTM International. You need to understand the grade. It ensures you get suitable mechanical properties for your use. However, remaining current is essential. They keep making better steel grades. They have new features.

These include higher strength-to-weight ratios and better corrosion resistance. Consult with good vendors. They will keep you up to date on the latest breakthroughs in carbon steel grades. Also, feel free to use the internet. Many steel associations and industry journals provide thorough grade selection guides. These guides explain the qualities and uses of various carbon steel grades.

2) Finishing

Carbon steel comes in many treatments. Each treatment affects its appearance and function. Common choices include:

- Hot-rolled steel has a rough surface. It is commonly used for structures because it is solid.

- Cold-rolled steel has a smooth surface. It’s great for applications needing a fine finish, like decorative parts.

- This has a zinc coating for corrosion resistance. It’s great for projects exposed to the outside, like railings or pipes.

Consider newer finishing options. For example, pre-painted steel can look good and resist corrosion. Understanding the various finishes helps you pick one. It will maximize both the usefulness and the looks of your project.

3) Supplier Reputation and Reliability

Choose a reputable supplier. They ensure consistent quality and on-time deliveries. They also provide access to technical help if needed. Research the supplier’s track record. Check customer reviews and certifications (e.g., ISO 9001 for quality management). Look for steel suppliers who prioritize ethical sourcing.

They should show a commitment to sustainability in their operations. Later, we will discuss how a good relationship with a trusted supplier can benefit you in the long run.

4) Cost and Pricing

The cost of carbon steel varies. It depends on market conditions, grade, quantity, and global factors. Obtain estimates from several vendors to evaluate prices and negotiate the best deal. Remember, the cheapest steel may not be the best. It could have issues with quality, service, or hidden costs like longer lead times.

Consider minimum order quantities and possible shipping surcharges when calculating expenses. Also, some vendors have flexible payment periods. It can be important when managing your project budget.

5) Availability and Lead Times

Ensure the steel grade and quantity you want are easy to get from your supplier. To avoid project delays, factor in production and delivery lead times. Modern technologies can help in this situation. Many steel suppliers have added online inventory systems.

These systems track stock levels and expected lead times in real time. This transparency lets you plan your project schedule better. It helps you avoid disruptions from unexpected delays.

6) Sustainability and Environmental Considerations

The globe is increasingly focusing on environmentally friendly methods. Some suppliers provide carbon steel made from recycled components. They also offer steel with minimal environmental impact.

Consider using sustainability principles in your purchases. Look into options such as steel with high recycled content. Also, consider steel made using energy-efficient procedures. Some vendors also include carbon footprint calculators. They can help you assess the environmental impact of sourcing options.

7) Technical Support and Services

A good supplier can offer much technical support. They can advise on material selection and fabrication. They can even help on-site. Look for a supplier who values customer service and technical skills.

It is vital if you’re working on a hard project or need specific fabrication. Also, some suppliers provide extra services. These include steel cutting, bending, and basic prefabrication. They can streamline your project and lower costs.

How to Source Carbon Steel?

Now you know the key things to consider when buying carbon steel. Now, let’s look at the practical steps to get the material for your project:

1) Local Suppliers vs. Global Suppliers

| Factor | Local Suppliers | Global Suppliers |

| Price | Potentially higher due to smaller order quantities and lower negotiation power. | May be lower due to economies of scale and bulk purchasing. However, consider import duties and transportation costs. |

| Minimum Order Quantity (MOQ) | Lower MOQs | Higher MOQs |

| Selection | May have a limited selection of grades and sizes. | May offer a wider variety of grades, sizes, and potentially specialized options. |

Both local and international providers have advantages and disadvantages. Here’s a breakdown between both suppliers to help you choose:

Local Suppliers:

- There are several advantages. These benefits include shorter lead times. They may also bring lower shipping costs. And the chance to build relationships with a nearby source.

- The disadvantage is that selection may be limited. Also, pricing may be less competitive than with worldwide vendors.

Global Suppliers:

- Global suppliers offer more grades, finishes, and volumes. It may lead to lower prices.

- The disadvantages are longer lead times. That’s because of overseas shipping and communication difficulties. These come from time zone differences.

- The steel industry uses e-commerce platforms. They will simplify the steel purchasing process for buyers like you. These online platforms have various benefits:

- Easier Supplier Discovery: Gone are the days of thumbing through interminable phone books. Online directories allow you to search for suppliers by their location. You can also search by the products they have and the unique services they offer.

- Real-time Quote Requests: No more waiting for email responses or phone calls. Online systems let you send quote requests directly to many vendors. It speeds up the process and allows price comparisons.

- Secure Online Transactions: You no longer have to worry about mailing checks. Many platforms provide secure online payment solutions. They ensure a smooth shopping experience.

- Modern online platforms offer real-time order tracking. You can use it to track your order and estimate delivery times. This transparency reduces surprises and keeps you informed throughout the buying process.

2) Identify Your Requirements

Specify the type and quantity of carbon steel you require. It includes:

- Give an ASTM International grade. Or, give a complete description of the relevant mechanical qualities.

- List the thickness, width, and length of the steel you require.

- Specify the total amount of steel needed for your project.

- Select your preferred finish, such as hot-rolled, cold-rolled, or galvanized.

- Are there any other requirements? These could include things like pre-cutting, bending, or special certificates.

You know your project’s requirements well. With this knowledge, you can efficiently get accurate bids from possible vendors.

3) Research Suppliers

Use the resources at your disposal to find possible suppliers. Here are a few strategies:

- Web Directories and industry associations feature steel suppliers in your area or worldwide.

- Industry Publications often include stories about suitable steel suppliers. They are in industry magazines and online news outlets.

- Ask colleagues, contractors, or DIYers with experience. They may give helpful suggestions from their own experiences.

Look at each vendor’s website. Do this after you’ve narrowed your list of possible suppliers. Look for details on their products. Also, look for their certifications, customer service, and dedication to sustainability. Consider using internet review services. They let you learn from other buyers’ experiences with various suppliers.

4) Request for Quotations (RFQs)

To the vendors you have identified, formally request a quote (RFQ). This document should include your needs. It should also include the delivery time you want and other vital details. Here’s what you should include in your RFQ:

Project Description:

- Say what your project is. Also, explain how you will use carbon steel.

- Provide the grade, size, and quantity of steel. Also, the finish you want.

- Provide your preferred delivery timeframe and location.

- Specify your payment terms (for example, net 30 days).

- Include any unique requests or queries you’ve received from the supplier.

Getting quotes from many suppliers allows price comparison. It helps you choose the best offer. However, don’t just focus on price. Consider the whole package. It contains lead times, payment terms, and delivery options. It also includes tech support. The supplier is committed to quality and responsible sourcing.

5) Evaluate Quotes

Evaluate the quotes you have received carefully. Here are some critical RFQ considerations to consider.

- Base price per unit is the beginning point for your cost comparison.

- Consider shipping fees and extra charges for cutting or bending. Also, consider any taxes.

- Consider the payment terms. Also, consider any early payment incentives.

- Lead times must work with your schedule.

- Evaluate the technical support provided by the supplier.

If a supplier’s quote is vague or incomplete, ask for clarification. The goal is to select a provider with the best value for your requirements.

6) Negotiate Terms

Do not be frightened to negotiate! Once you’ve picked a suitable supplier, talk about the quote terms. Negotiation is common in the steel industry. Good negotiations can cut costs.

- Determine the base price per unit of steel.

- If applicable, ask about potential volume discounts on bigger orders.

- Discuss better payment terms. These could be longer repayment periods or early payment discounts.

- Discuss delivery choices and potential shipping cost savings.

Remember to stay calm and wise throughout the bargaining process. A strong and friendly connection with your supplier might benefit you in the long run. It will lead to better service and possibly special treatment.

7) Consider Logistics

Consider transportation costs and logistics when making your decision. Here’s what you should consider:

- Specify where the steel will be delivered, including any unloading needs.

- Consider the distance and quantity. Consider truck, rail, or ocean shipping for large international orders.

- Get shipping costs. Get quotes from trustworthy carriers. Or compare the supplier’s shipping options.

- Look for strategies to reduce the environmental impact of transportation. It could include using local suppliers. It could also mean optimizing shipping routes. Or, it could mean participating in carbon offset programs offered by some carriers.

8) Build Relationships

Getting close to your carbon steel supplier can help you in the long run. Here’s how:

- Stay in clear contact. Keep it open and consistent with your supplier. Do this throughout the purchasing process.

- Paying invoices on time helps you build a strong connection with your supplier.

- Give your supplier constructive comments about your positive or bad experience.

A great provider will appreciate your business. They will always seek to improve their service. Today’s world is interconnected.

Online supplier portals can help you communicate and manage orders better. They will improve your relationship with the supplier. Also, many suppliers offer loyalty programs. These encourage repeat business and lead to extra cost savings on future purchases.

9) Monitor Supplier’s Performance

Once you’ve chosen a supplier, keep track of their performance. Here is what to track:

- Delivery Times: Was the steel delivered on time as promised?

- Quality: Did the steel meet the stipulated grade and dimensions?

- Communication: Did the supplier communicate clearly throughout the process?

Tracking these lets you judge the supplier’s dependability. They also help find ways to improve. A good provider will listen to your issues. They will seek to keep improving their service. Again, modern technology can be helpful in this situation.

Many suppliers use online order monitoring systems. They give immediate updates on your order’s status. It lets you anticipate any potential delays.

Buying Carbon Steel – Key Takeaways for You!

Buying carbon steel may need to be clarified. But, with the proper study and resources, you can make good choices. Remember, the key is to understand your steel needs. Choose the right quality from a reliable source. Embrace tech progress and prioritize sustainable sourcing. Here is a quick recap:

- Understand your needs. Before diving into carbon steel, clearly describe your project’s goal and needs.

- Choose Wisely. Pick the correct grade of carbon steel based on its qualities and your specific use.

- Find a Reliable Partner. Develop partnerships with trustworthy suppliers. They offer top products, excellent service, and a commitment to ethical sourcing.

- Embrace Technology. Use Internet platforms to make shopping easier. They give access to valuable materials and keep you up to date on industry trends.

- Think Green. Consider the effect of your purchase on the environment. Look into choices such as recycled steel or vendors that use sustainable techniques.

Follow these steps. They will prepare you to buy carbon steel confidently. Remember, informed decisions help your project succeed. They also allow the material to last and be dependable.

Stay up to date! The steel business is constantly developing. Stay up to date on industry trends, new grades, and tech breakthroughs. Also, learn about sustainable sourcing. It will help you make informed decisions for future projects. Keep up with these changes. Act on them to keep getting carbon steel. You’ll get it sustainably and efficiently for many years to come.

A Look at the Future of Carbon Steel

The future of carbon steel is bright. Here’s a preview of what is ahead:

- Environmental awareness is a driving force. Expect recycling technology to improve. It can boost the use of recycled content in making carbon steel. Furthermore, studies into alternate production methods with a lower environmental impact are in progress.

- Steel manufacturers are continually creating new grades with improved qualities. These could include steels with higher strength-to-weight ratios. They could also have better corrosion resistance or self-healing properties. Staying informed about these breakthroughs will help you use the newest tech for your projects.

- Digitalization and Automation are gaining traction. They will bring more change to the steel industry as Industry 4.0 grows. Expect more automation in the industry. Also, real-time data analysis can be expected to optimize resource use. And expect AI to streamline supply chain management.

- The sourcing landscape is evolving. E-commerce platforms will play a bigger role. They offer simpler supplier discovery, streamlined communication, and more transparent pricing. Also, blockchain technology is advancing. It holds promise for clearer traceability and transparency in the supply chain.

FAQs:

1) What Are the Major Advantages of Using Carbon Steel?

Carbon steel has many advantages. It is a popular choice in many industries.

- Outstanding value is provided by carbon steel. It is a reasonably priced alternative that is yet quite powerful and effective.

- Consider carbon steel as a highly versatile member of your building team. It can also be made to meet the needs of almost any project. This is due to its variety of grades and coatings.

- Carbon steel is strong. It is also durable, so it is ideal for demanding uses.

- Workability varies by grade. Carbon steel is easily welded, cut, and shaped. It allows for greater production flexibility.

2) How Can You Choose the Right Carbon Steel Grade for Your Needs?

Understanding the project’s needs is necessary for selecting a suitable grade. Consider factors such as:

- Applied Load: The weight or force that the steel must withstand.

- Environment: Corrosion, severe temperatures, and other external variables can all cause damage.

- Desired Formability: How easily the steel may be bent or shaped.

Check industry standards, like ASTM International. Or, ask a good steel supplier for advice. They can help you find the best grade for your needs. Also, use online resources. Many steel suppliers and industry groups provide detailed guides on grade selection. They also offer tech support papers.

3) What Are the Common Challenges in Sourcing Carbon Steel?

Some obstacles include:

Market Fluctuations: Global steel prices go up and down due to supply and demand. They affect your purchase choices. Reading industry magazines or supplier updates can help you stay current. They keep you up to date on market developments. It can help you navigate these shifts.

Availability Issues: Obtaining suitable steel may require longer lead times. This is especially true when buying from foreign vendors. The lead times depend on the grade and amount. Working with a dependable supplier is critical. They have open communication channels. It will help you control lead times.

Finding Genuine Suppliers: Quality Control is critical. You must pick a reputed provider. They must keep up with consistent quality and follow industry standards. Ask your supplier for mill certificates. They show if the steel has the right chemicals and qualities. The certificates confirm that steel meets key industry standards, like ASTM International. They also confirm that it meets project specifications.

4) How to Ensure the Carbon Steel You Purchase Meets Regulatory Standards?

Trusted steel suppliers will provide mill certifications. These documents show the steel’s chemistry and strength. These certificates certify that steel meets industry standards. The standards include those of ASTM International.

They also meet project specifications. Also, some suppliers offer certification programs. These go beyond basic norms. They guarantee that steel meets specific performance requirements for critical applications.

For example, a construction project needs steel for a high-rise building. It may have stricter fire resistance or seismic criteria. Certification programs are from good vendors. They ensure steel meets these requirements.

5) Are There Any Special Considerations for Working With Carbon Steel?

Absolutely! If you’re a first-time buyer or working with a new grade of steel, keep these items in mind:

Always prioritize safety when working with carbon steel. Wear enough PPE. It includes gloves, safety glasses, and sturdy boots. Learn safe handling procedures. Study safety data sheets (SDS) for each grade.

Start small. If you’re unsure about a grade, begin with a small test. This lets you experiment with fabrication processes. You can get to know the material before starting a larger project.

Don’t be afraid to seek help! Reputable steel suppliers often employ skilled staff. They can answer your concerns and give helpful advice. This advice may be on picking the correct grade. It may be working with the material or fabrication procedures. Online resources and industry forums can also be excellent sources of info for newcomers.

6) Does Cutting or Welding Carbon Steel Need Specialized Equipment?

The answer depends on steel’s thickness. It also depends on the needed precision.

Thin Sheet Metal: Simple hand tools such as tin snips or hacksaws may suffice. However, thicker materials or delicate cuts need power tools. For these reasons, we use metal shears or bandsaws.

Welding: Welding carbon steel demands specialized tools and skills. If you’re a beginner, consider hiring a pro welder. Or take a welding course to learn safe and proper practices. Some steel suppliers may offer basic fabrication services. These may include cutting or bending. They might be a good choice for small tasks.

7) How to Store Carbon Steel to Prevent Rust?

It can rust if carbon steel comes into too much contact with moisture. Rust can be avoided. Your steel may keep its best look with good storage and care. Here are some suggestions for good storage:

- Whenever feasible, give your carbon steel a comfortable indoor home! A dry, well-ventilated room is excellent.

- A light oil layer on the carbon steel’s surface will act as a barrier against moisture. It will ward off the rust.

- Wrap the steel tightly for long-term storage. Use moisture-resistant materials like oiled paper or plastic wrap.

- Don’t store steel directly on the ground. It may get damp and corrode. Use pallets or wooden blocks to elevate steel and enable air to circulate.

8) Which Steel Is Better Between Hot-Rolled Steel and Cold-Rolled Steel?

Hot-rolled steel has a rough surface. It is due to the high-temperature rolling process. It is often stronger and less expensive but less visually appealing. Hot-rolled steel is suited for structural applications where strength is a top priority.

Cold-rolled steel has a smooth, polished surface. This surface is created by rolling the steel at room temperature. It provides greater dimensional precision and a more visually appealing appearance. Cold-rolled steel is suitable for applications needing a fine finish. These include decorative features or pieces that will be painted.

Your individual project needs will determine whether you choose hot-rolled or cold-rolled steel. Keep the desired finish, strength, and budget in mind when choosing.

Final Thoughts!

You must understand it today to be an informed buyer in the changing carbon steel world. You must also embrace new technology and focus on sustainability. Carbon steel remains a crucial material. With responsible sourcing and innovation, it will continue to play a vital role. It will help shape a stronger and more sustainable future.

Don’t let suboptimal carbon steel choices compromise your project’s success. Ensure you make an informed decision to meet your quality standards and budget. You can seek Alloyxpert’s expertise in this regard.