A vast network of gas and oil pipelines silently crisscrosses each area. They supply the hydrocarbons that power our industrial, heating, and transportation systems. However, several risks can threaten the integrity and operation of these vital lifelines. It could have disastrous results.

This post will include the top five problems encountered by oil and gas pipelines. It also shows the crucial role of steel in building solid and dependable pipelines. The pipes must withstand the energy industry’s ever-changing needs. Understanding these problems is vital.

For years, we have also needed to grasp the solutions offered by advanced steel pipes. They ensure the safe and effective movement of gas and oil. It directly impacts our energy’s safety and reliability.

Key Highlights!

- Safe oil and gas transportation relies on strong pipelines.

- Common issues include corrosion, material defects, mechanical damage, operational issues, and cracking.

- Advanced steel pipes by Alloyxpert offer superior solutions to these challenges.

- They provide exceptional corrosion resistance, mechanical strength, and operational efficiency.

- Our pipes are built for a sustainable future, minimizing environmental impact.

The Top Five Typical Problems with Gas and Oil Pipelines

Pipelines are generally a safe way to move energy resources. However, they do face some recurring issues and challenges. The top five typical problems that can affect pipeline operations include the following.

1) Corrosion

Corrosion is the relentless decay of a material due to its environment. It poses a significant threat to oil and gas pipelines. It appears mainly in two ways, each of which calls for a focused defense plan:

-

A) Interior Corrosion

Internal corrosion arises from a relentless chemical attack on the pipeline’s interior wall. This attack results from the transported oil or gas interaction and the steel itself. Several factors can exacerbate this threat:

Water Presence

Water trapped in the pipeline makes acids. Dissolved carbon dioxide (CO2) or hydrogen sulfide (H2S) can cause this corrosion. These acids can eat away at the steel wall, causing pipe wall weakness and leaks.

High H2S Content

Pipelines carry crude oil or natural gas. They contain hydrogen sulfide (H2S), which poses a particular threat to pipelines. The steel in these pipelines can react with H2S to form iron sulfide. Iron sulfide is a brittle compound. This iron sulfide weakens the pipeline wall, making it much more likely to crack.

Content of CO2

Another stream component, carbon dioxide (CO2), adds to the corrosion problem. CO2 can dissolve in water present within the pipeline, forming carbonic acid. This acid adds to internal corrosion and is a significant threat to pipelines. The steel in these pipelines can react with H2S to form iron sulfide, a brittle compound. This iron sulfide is in the pipeline wall.

-

B) External Corrosion

This hazard results from the contact of the exposed or buried pipeline with the nearby water or soil. Typical reasons for exterior corrosion include:

Stray Electrical Currents

Pipes can corrode locally. It can happen from underground electric currents. The currents often come from poorly grounded power lines. Or they come from nearby cathodic protection systems for pipes.

Microbial-induced Corrosion (MIC)

Some bacteria in the water or soil can quicken the corrosion process. The bacteria can create micro-environments that encourage corrosion of the steel.

What Are the Consequences of Corrosion?

Ignoring pipeline challenges leads to a series of bad results. Unchecked internal and external corrosion can cause significant pipe wall thinning. This thinning increases the risk of leaks. They allow the product to escape into the environment. Leaks disrupt operations. They can contaminate soil and water.

They cause considerable financial losses from product spillage. In rare cases, rust inside the pipe can weaken it. That can make it burst. Ruptures in pipelines pose a severe risk. They can cause fires and explosions, endangering public safety and worsening environmental harm. External corrosion can also cause leaks and ruptures.

However, it presents additional concerns about harming the environment through contaminated soil.

2) Material Defects

The materials used to build a pipeline determine its integrity and strength. Sadly, errors in manufacturing or welding can weaken the steel. These weak spots are prone to failure.

Manufacturing Defects

During steel production, inclusions are foreign particles trapped inside the steel. Steel can also have voids, which are gas bubbles or a non-uniform grain structure. These flaws concentrate on tension. They make the pipeline likely to break or fail under pressure.

The key to reducing such rigorous quality control flaws is to use them in steel production. It shows the key role each of us plays. We must ensure the integrity of our pipelines.

Welding Defects

Weak areas in the pipeline might come from lousy welding methods. The welds might not go in deep enough. These places serve as crack initiation sites. They may compromise the pipeline’s integrity.

High-quality welds need highly qualified welders who follow exacting welding processes. These flaws can be found before the pipeline is used. It is done with advanced non-destructive testing (NDT) methods. These include ultrasonic testing and X-ray radiography.

What Are the Consequences of Material Defects?

Material flaws add up. They might reduce pressure and loads in a pipeline. Cracks may form at these fault lines. They could cause leaks or ruptures with severe consequences. Such damage can also be difficult and costly to restore.

3) Mechanical Damage

Pipelines carrying oil and gas are not impervious to the elements or human activity. Significant harm from these outside factors can jeopardize the pipeline’s structural integrity.

Third-Party Interference

This danger looms in heavily inhabited areas or places where construction is ongoing. Excavation or construction equipment can accidentally puncture or crush pipelines. It causes leaks and harms the environment.

Clear excavating permits and thorough pipeline mapping are essential. Pipelines can also be underground. Damage can be avoided with pipeline tracking systems like Global Positioning Systems (GPS). We can run campaigns for public awareness in places where pipelines are buried. These campaigns focus on the value of safe excavation techniques.

Ground Movements

Natural events, like earthquakes and landslides, can cause large ground movements. Subsidence, or the steady lowering of the earth, can also cause these movements. These motions may severely stress pipelines, possibly bending or even bursting.

Mitigation strategies are essential in places vulnerable to ground changes. They require robust pipeline design and construction techniques. For example, the shifting of the ground can be avoided. You can do this by using thicker pipes. You can also use flexible coatings or bury pipelines deeper.

Research done before building a pipeline can find regions that might move. It can also guide the choice of suitable mitigation measures.

What Are the Consequences of Mechanical Damage?

Mechanical damage can sometimes result in catastrophic results. Leaks or ruptures from outside can disrupt operations. They spill dangerous oil or gas and harm the environment. They also seriously endanger residents’ safety. Repairing such harm can be complicated and costly.

4) Operational Issues

Pipelines carrying gas and oil must be carefully balanced inside the system. Unexpected problems can arise when operating settings are far from optimal.

Pressure Variations

Sudden pressure changes are a danger. They can severely stress the pipeline’s walls and welds. Inappropriate management of this tension might result in leaks or even catastrophic ruptures.

Stable pressure inside the pipeline depends critically on pressure monitoring and control devices. Sometimes, it takes pressure relief valves to release extra pressure. They save pipelines from harm automatically.

Temperature Variations

Extreme temperature swings might cause the pipeline to expand or constrict considerably. Heat expansions and contractions cause pipeline stress concentrations. They may lead to leaks or damage.

Temperature fluctuations can be reduced in pipeline materials. They do this by having a low coefficient of thermal expansion. Adding loops or bends can also help with size changes. They prevent stress on pipes that face big temperature swings.

Flow Assurance Issues

Wax oil/gas pipelines have temperature and pressure fluctuations. These can lead to hydrate (ice crystal) formation. They can also cause wax deposits to build up inside the pipeline. These obstructions can block flow and interfere with operations. Removing them requires extra steps.

Maintaining a specific temperature range within the pipeline mitigates wax or hydrate formation. This can involve using additives to change how the product flows. It can also affect heating pipeline systems. Pigging also removes built-up wax, keeping the flow efficient.

What Are the Consequences of Operational Issues?

Operational problems can harm pipeline efficiency and safety, and leaks are caused by temperature or pressure changes. They may have financial and environmental consequences. Flow assurance problems can cause production losses.

They need extra cleaning or pigging to keep the flow going. If we don’t fix operational issues soon, they will worsen other pipeline problems. They also raise the risk of catastrophic failures.

5) Cracking

Cracks seriously threaten pipeline integrity since they breach the pipeline’s defense mechanism. Two main types of cracks can form. Each needs a different prevention strategy.

Stress corrosion Cracking

Tensile tension and a corrosive environment can cause stress corrosion, cracking, or SCC. Over time, the pipeline wall can break down. Tension and soil chemicals, like H2S or chlorides, can cause cracks.

Choosing the appropriate steel grade for the particular working environment is essential. High-toughness steels provide superior resistance against the beginning and spread of cracks. Other ways to cut residual stresses in the pipeline include advanced welding techniques.

You can also use stress-relieving techniques after welding. Last, coatings resist corrosion. They shield the pipeline from outside substances that cause SCC.

Fatigue Cracking

This kind of crack forms when a pipeline is repeatedly loaded and unloaded. These cycles can be caused by pressure swings or vibrations from nearby machines. This is especially true in areas with existing faults or stress points.

The repeated loads may cause cracks from fatigue and make them spread. In contrast to SCC, fatigue cracks form where stress varies. This is unlike where stress is constant. These might be sections with sharp variations in pipe diameter, bends, or welds. Even minor flaws in these spots can significantly speed up fatigue cracking.

What Are the Consequences of Cracking?

Cracking can have disastrous results. With time, even little fissures can enlarge and cause leaks or ruptures. These malfunctions might endanger the public. They could disrupt activities and release toxic substances. The location and degree of the damage determine how complex and costly crack repairs might be. Sometimes, replacing the pipeline entirely is required.

How Can You Avoid These Pipeline Issues?

Pipeline operators cannot completely eliminate such problems. However, there are steps you can take to prevent these typical issues.

1) Material Selection

You must choose the steel grade with the best resistance. It must resist the start and spread of fatigue cracks. We must carefully consider the steel’s strength, toughness, and fatigue resistance. This is due to the expected pressures and cyclic loading.

2) Stress Management

Lowering stress concentrations in the pipeline can significantly decrease fatigue cracking. Optimizing pipeline design helps. It does this by avoiding abrupt bends and using stress-relieving methods after welding. Sophisticated computer modeling software makes it possible to examine stress inside the pipeline. It helps us make well-informed design decisions to reduce stress points.

3) Regular Inspections

We can use cutting-edge NDT methods, like ultrasonic testing. They can help us find cracks early before they become serious. Early identification makes prompt repair and a reduced chance of catastrophic failures possible. Age, state, and risk will decide how often and which NDT methods are used.

4) Pipeline Monitoring Systems

ILI equipment can travel inside the pipeline. It finds areas where the wall is thinned or might start to fracture. Long-distance pipelines might be too long for regular inspections. These smart technologies help a lot. They provide vital data for checking pipeline integrity.

How Can Our Steel Pipes Help Solve Oil and Gas Pipeline Issues?

Let’s examine how our advanced steel pipes can fix the top five problems facing oil and gas pipelines.

1) Superior Corrosion Resistance

Standard pipeline steel provides a base degree of corrosion resistance. But our steel pipes are special. They include elements like nickel, molybdenum, and chromium. These elements provide a significant barrier against internal and external rust.

High-Nickel Alloys

We provide steel grades with more nickel. They are for pipelines that move materials with a lot of H2S. These alloys have a vital barrier function. They reduce the chance of SCC and stop H2S from getting into the steel.

Duplex Stainless Steels

Our novel duplex stainless steel products are solid. They also resist many corrosive elements, like H2S and chlorides. This makes them perfect for pipelines. They move high-chloride fluids or work in demanding offshore conditions.

Clad Steels

We supply layered construction-clad steel pipes. The outer layer resists corrosion. It is often made of stainless steel or a high-nickel alloy. The outer layer is joined to a more robust but less corrosion-resistant inner layer. This combination keeps the inner layer solid and cheap. It also adds excellent corrosion resistance.

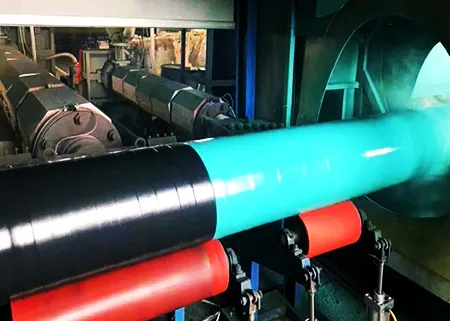

Coated Steel Pipes

Our method uses several layers in addition to sophisticated alloys. We coat our steel pipes inside and out. We use polymeric coatings, like epoxy or polyethylene. They form a strong barrier against corrosion, extending pipeline life. The coating we choose depends on the corrosion threats. It also depends on the expected operating conditions. Our professionals can help you choose the best steel grade and coating for your project.

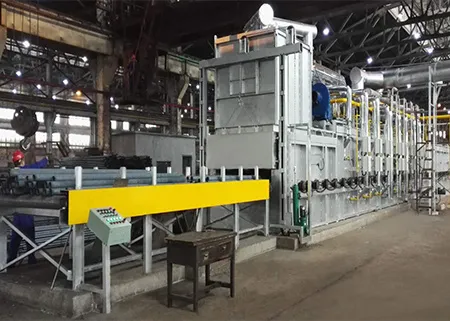

2) Superior Materials and Production

We begin our dedication to quality with the steel itself. Thus, we use premium raw materials and strict quality controls. We use them throughout the steel-making process to cut the chance of flaws like inclusions or voids.

To ensure the integrity of every weld, we also follow strict welding rules. We use cutting-edge NDT methods. They make steel pipes very strong. This is due to their unwavering focus on quality.

3) Exceptional Mechanical Strength

External stresses and high pressures are no match for modern pipeline design. These several developments allow our steel pipes to have this remarkable mechanical strength:

Micro-alloying

We refine the steel’s grain structure by adding trace elements. These include niobium, vanadium, and titanium. They are added throughout the steel-making process. This change makes the steel more rigid and robust.

It also gives it better resistance to bending and cracking. Micro-alloyed steels can save much weight compared to conventional pipeline steels. They keep the needed strength. Savings and easier pipeline installation follow this, especially for long-distance pipelines.

High-strength, Low-Alloy (HSLA) Steels

Our HSLA steels have excellent strength-to-weight ratios. They let us build pipelines with thinner walls. The pipelines can still handle the necessary pressure. It may result in savings and, likely, easier pipeline installation. HSLA steels make sense for pipelines. They run under moderate pressure, such as onshore pipes moving refined products.

Quenched and Tempered (Q&T) Steels

These steels undergo a particular heat treatment that includes quick quenching and tempering. This process boosts the steel’s strength.

It is excellent for pipes in high-pressure settings where the ability to support large loads is vital. Pipelines move natural gas or heavy crude oil over great distances. They are often made of Q&T steel.

4) Operational Reliability

Our steel pipes are made to perform reliably over their whole working life. The pipeline benefits from strength, corrosion resistance, and high-quality materials. Good manufacturing also helps. It can handle the demands of continuous operation. The smooth finish on our steel pipes reduces flow resistance. It lowers pumping energy needs and improves efficiency.

5) Crack Prevention Technologies

As mentioned before, pipeline integrity is seriously threatened by cracks. Multiple characteristics are included in our steel pipes to reduce this risk:

Various Grades Available

We offer a selection of steel grades. They are designed to resist the start and spread of cracks better. Our specialists can help you pick the best steel grade for your project. They will consider the operating conditions and any cracking hazards.

Modern Manufacturing Methods

We constantly improve our steel manufacturing to cut the number of flaws. These flaws could be places where cracks start.

Excellent Stress Management

We work with pipeline experts. They ensure the best pipeline design. It reduces stress all along the pipeline. Optimization of pipeline geometry, avoiding abrupt. It can include sharp bends, changes in diameter, and expansion loops. These allow for thermal expansion.

Quality Inspection and Control

Regarding quality, we don’t stop at the production line. We provide thorough inspection services. We use cutting-edge NDT methods to find flaws or cracks before servicing the pipeline. Moreover, we can also offer continuous pipeline integrity assessment services. They track the pipeline’s health over its working life.

These solutions prevent cracks. They provide a significant barrier against this threat in our steel pipes.

| Property | Ordinary Steel Pipes | Alloyxpert Steel Pipes |

| Corrosion Resistance | Moderate | Superior |

| Internal Corrosion | Susceptible to internal corrosion from H2S, CO2, and water

|

High Nickel Alloys, Duplex Stainless Steels, Clad Steels, and coated pipes for exceptional internal corrosion resistance |

| External Corrosion | Vulnerable to external corrosion from stray electrical currents and MIC | Enhanced corrosion resistance due to special alloys and coatings |

| Mechanical Strength | Good | Exceptional |

| Wall Thickness | Requires thicker walls to handle pressure | Micro-alloyed HSLA Steels, and Q&T Steels allow for thinner, lighter weight pipes while maintaining strength |

| Resistance to Pressure & Stress | Moderate | High-strength steels can withstand high pressure and external stresses |

| Operational Efficiency | Standard | Improved |

| Flow Resistance | Higher flow resistance | Smooth surface finish reduces flow resistance, lowering pumping energy needs |

| Durability | Moderate | Extended lifespan due to superior corrosion resistance and high-quality materials |

Why Do Companies Prefer Alloyxpert‘s Oil and Gas Pipelines?

Oil and gas companies are using our steel pipes more for their pipeline projects. This is because of several key advantages:

1) Economical

We offer many steel grades and pipe layouts. They meet varied project specs and budgets. We emphasize better materials and manufacture. So, pipes last longer and need fewer replacements. It cuts related costs. Also, our steel pipes are so strong that thinner pipes can sometimes be used. This can save on material costs.

2) Customization

We understand that all pipeline projects are unique. We offer extensive customization to satisfy your particular requirements. It involves choosing a coating, wall thickness, pipe diameter, and steel grade. They must fit your project’s operating and environmental needs. Our team of steel experts can work with you. We can create a pipeline system that maximizes performance, safety, and economy.

3) Easy Installation

Our steel pipes are made to be installed safely and effectively. Constant measurements and a flawless finish make welding easier. They also reduce the chance of installation problems. We may also offer professional help during the installation. It will guarantee the correct handling and setup of our pipes.

4) Sustainability

We pledge to use sustainable methods throughout the pipe and steel manufacturing processes. When possible, we use recycled steel. It reduces our need for new materials. Also, our steel pipes last a long time. This lessens the need for regular replacements and their resulting environmental effects. Our pipes are very efficient. They also save the energy needed to move products.

Final Thoughts!

Oil and gas are still essential to the world’s energy mix. Pipelines are the cheapest way to move these resources. They are the best medium to travel long distances. Still, it is critical to guarantee the pipelines’ environmental responsibility and safety.

We can use cutting-edge steel technology. It can help us build a new generation of gas and oil pipelines that are:

- Excellently corrosion-resistant on the inside as well as the outside

- Solid and resilient to extremes of pressure and outside stresses

- Advanced methods of welding provide robust and dependable pipeline connections.

- Adaptable to satisfy the particular needs of every assignment.

- Sustainable, emphasizing the reduction of environmental effects during the whole lifecycle.

We are dedicated to invention, even outside of steel. Thus, we work with research organizations, pipeline engineering companies, and inspection service providers. We work with them to improve pipeline design, construction, and maintenance. This cooperative strategy creates a strong and sustainable oil and gas transportation network.

Oil and gas pipelines must balance environmental responsibility, operational effectiveness, and economic feasibility. The pipelines use high-tech steel and creative designs. They focus on sustainability. It will protect our environment for future generations. They will also stay essential for addressing global energy needs.