Table of Contents

What is Stainless Steel Coils Composition?

Stainless steel coils are versatile rolls made primarily from a combination of iron, carbon, chromium, and other elements like nickel and molybdenum. These components provide the coils with unique properties essential for various industrial applications:

Iron: Provides foundational strength and structure.

Carbon: Enhances hardness and strength.

Chromium: Forms a protective oxide layer, crucial for corrosion resistance.

Nickel: Increases ductility and further improves corrosion resistance.

Molybdenum: Enhances resistance to pitting and crevice corrosion.

→ Click here to check our Stainless Steel Coil Factory!

Where are Stainless Steel Coils Used?

Stainless steel coils find widespread use across various industries due to their corrosion resistance, durability, and aesthetic appeal. Common application areas include:

Construction

Used in structural components, roofing, cladding, and reinforcement. The corrosion resistance makes stainless steel coils ideal for long-lasting infrastructure.For example, stainless steel is used in building facades and bridges where durability and minimal maintenance are critical.

Automotive

Employed in various automotive components such as exhaust systems, trim, grilles, and other decorative and functional parts. Resistance to corrosion and high temperatures is crucial in this industry. Stainless steel is commonly found in the exhaust systems of high-performance cars, providing both durability and an attractive finish.

Applications

Preferred for appliances like refrigerators, stoves, dishwashers, and other kitchen appliances. They offer a modern and sleek appearance while resisting stains and corrosion from daily use. For instance, stainless steel refrigerators are popular in contemporary kitchens due to their stylish look and ease of cleaning.

Industrial Equipment

Utilized in tanks, pipelines, valves, and machinery parts. Their corrosion resistance, high strength, and ability to withstand harsh conditions make them suitable for diverse applications. Stainless steel tanks are commonly used in the food and beverage industry to store liquids safely without contamination.

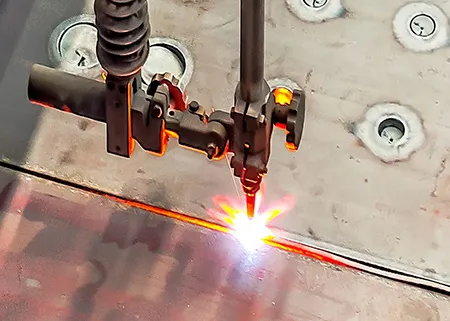

What are Stainless Steel Coils Welding Methods Available?

When considering on-site welding of stainless steel coils, several welding methods can be employed:

TIG (Tungsten Inert Gas) Welding

Known for its precision and control, TIG welding is suitable for thinner materials and provides high-quality, clean welds.

Suitable Thickness: TIG welding is ideal for thin to medium thickness stainless steel coils, typically ranging from 0.5 mm to 6 mm.

Precision and Cleanliness: TIG welding provides precise control over the welding arc and filler material, resulting in clean, aesthetically pleasing welds.

Technique: Use a non-consumable tungsten electrode and an inert shielding gas, typically argon, to protect the weld pool.

MIG (Metal Inert Gas) Welding

Ideal for thicker materials and higher deposition rates, MIG welding offers efficiency and speed.

Suitable Thickness: MIG welding is suitable for medium to thick stainless steel coils, generally ranging from 1 mm to 12 mm.

Efficiency and Speed: MIG welding is known for its efficiency and high deposition rates, making it suitable for larger projects.

Technique: Use a consumable wire electrode and an inert gas or gas mixture, such as argon with a small percentage of oxygen or CO2, to shield the weld area.

SMAW (Shielded Metal Arc Welding)

Also known as stick welding, SMAW is versatile and can be used in various environmental conditions. It is suitable for thicker materials and field repairs.

Suitable Thickness: SMAW is suitable for thicker materials, typically above 3 mm, and is often used for repair work and outdoor applications.

Versatility: SMAW is versatile and can be used in various environmental conditions, making it suitable for field repairs.

Technique: Use a consumable electrode coated in flux, which melts to form a protective gas and slag layer over the weld.

What are Welding Performance Indicators of Stainless Steel Coils?

Corrosion Resistance

One of the critical properties of stainless steel coils is their corrosion resistance. Welding should not compromise this property, and proper techniques must be employed to maintain it. Techniques such as using low-carbon filler materials and shielding gases like argon can help prevent oxidation and maintain corrosion resistance. Additionally, post-weld cleaning and passivation are essential to restore the protective chromium oxide layer on the surface.

Aesthetic Finish

Stainless steel is often chosen for its attractive appearance. Welding should not result in discoloration, pitting, or other defects that affect the aesthetics. Using TIG welding can help achieve clean and precise welds with minimal discoloration. Employing back-purging with inert gas during welding can also prevent oxidation and ensure a smooth, aesthetically pleasing finish. Post-weld polishing and buffing can further enhance the appearance of the welded joints.

Mechanical Properties

Welded joints should retain the strength and integrity of the base material. This ensures that the structure maintains its structural stability and durability. Techniques such as preheating and controlled cooling can reduce thermal stress and prevent cracking. Selecting appropriate welding parameters like current, voltage, and travel speed is crucial to achieving sound welds with optimal mechanical properties. Performing non-destructive testing (NDT) methods, such as ultrasonic testing or X-ray inspection, can verify the integrity and strength of the welds.

How do Environmental Conditions Impact on Welding?

Temperature

Cold temperatures can affect the flow of the molten metal, leading to potential defects in the weld. Preheating may be necessary in colder environments.

Critical Temperature Range for Welding: The ideal welding temperature for stainless steel coils is between 10°C to 32°C (50°F to 90°F).

Cold Temperature Effects: Welding below 10°C (50°F) can affect molten metal flow, potentially leading to defects.

Preheating Temperature: Preheating may be necessary in colder environments, with preheat temperatures ranging from 150°C to 200°C (300°F to 400°F).

Humidity

High humidity can introduce hydrogen into the weld, causing embrittlement and potential cracking. Proper shielding gas and control of humidity levels are essential.

Acceptable Humidity Levels: Optimal welding humidity is below 70%. Maintaining humidity levels within this range helps to minimize the risk of hydrogen-induced issues.

High Humidity Effects: Above 70% humidity can introduce hydrogen into the weld, causing embrittlement. To mitigate this, use high-quality shielding gases like argon with a low moisture content and implement humidity control measures in the welding environment.

Hydrogen Levels: Hydrogen concentration should be maintained below 5 mL/100 g of weld metal. This can be measured using techniques like thermal desorption analysis or gas chromatography, ensuring the weld metal remains free from detrimental hydrogen levels.

Contamination: Contaminants such as dirt, oil, or grease on the surface of stainless steel can lead to poor weld quality. Thorough cleaning before welding is crucial.

Surface Contamination: Contaminants such as dirt, oil, or grease should be below 25 mg/m². This can be measured using gravimetric analysis after solvent extraction to ensure cleanliness.

Cleaning Standard: Thorough cleaning with solvents or degreasers is crucial. Standards such as ISO 8501-1 Sa 2.5 or SSPC-SP 10 specify the cleanliness levels required for optimal welding conditions.

Surface Roughness: Surface should have a roughness average (Ra) of 0.5 to 1.5 µm for optimal welding quality. This can be measured using a profilometer to ensure the surface is adequately prepared for welding.

What are Requirements for Welding Equipment and Processes?

Cleanliness

Stainless steel surfaces must be meticulously cleaned before welding to ensure proper fusion and prevent contamination. This includes removing any oils, paints, or coatings.

Surface Cleanliness Standard: Stainless steel surfaces should be cleaned to a cleanliness level of ISO 8501-1 Sa 2.5 or SSPC-SP 10.

Contaminants Limit: Contaminants such as oils, paints, or coatings should be below 25 mg/m².

Surface Preparation: Mechanical methods like grinding should achieve a surface roughness of Ra 0.5 to 1.5 µm.

Gas Quality

TIG and MIG welding require high-quality shielding gas, typically argon or a mixture, to protect the weld from atmospheric contamination.

Shielding Gas Purity: Argon gas used for TIG and MIG welding should have a purity level of 99.995%.

Gas Flow Rate: Maintain a gas flow rate of 10 to 25 cubic feet per hour (CFH) for TIG welding and 20 to 40 CFH for MIG welding.

Gas Mixture: In some cases, a gas mixture such as argon with 2% oxygen or 5% hydrogen may be used for specific applications.

Power Supply

On-site welding requires a reliable power source to ensure consistent weld quality. Voltage fluctuations can affect the stability of the arc and the overall weld.

Voltage Stability: Voltage fluctuations should be within ±5% of the required welding voltage.

Power Source Rating: Use welding machines with an output rating suitable for the thickness of the stainless steel coil being welded.

Frequency: Power source should have a frequency range of 50-60 Hz for stable welding.

What are Steps and Procedures for On-Site Welding?

Surface Treatment and Preparation

Proper surface preparation is crucial for successful welding of stainless steel coils:

- Cleaning: Thoroughly clean the surface to remove dirt, oil, grease, and other contaminants. Solvents or degreasers may be necessary.

- Grinding: Smooth out any rough areas or imperfections on the coil’s edges. This ensures better welding performance and a clean, strong joint.

- Fit-up: Ensure the proper alignment of the coil edges before welding. Misalignment can lead to weak joints and defects.

Post-Welding Treatment

Post-welding treatment is essential to ensure the integrity and longevity of the weld:

- Inspection: Conduct thorough inspections of the welds to detect any defects or inconsistencies. Non-destructive testing (NDT) methods such as ultrasonic testing or radiography may be employed.

- Cleaning: Remove any slag, spatter, or discoloration resulting from the welding process. Pickling paste or other suitable cleaning agents can be used.

- Passivation: Apply passivation techniques to restore the corrosion resistance of the stainless steel. This may involve chemical treatments to form a protective oxide layer.

How to Handle and Store of Welded Coils?

Proper handling and storage are critical to maintaining the quality of welded stainless steel coils:

Handling

Use appropriate lifting equipment such as cranes or forklifts with non-abrasive slings to avoid damaging the coil surface. Ensure that no sharp objects or abrasive materials come into contact with the coil during handling.

Storage

Store the coils in a dry and clean environment to prevent corrosion. It is recommended to maintain a temperature between 15°C to 25°C and relative humidity between 40% to 60% to minimize corrosion risks.Use protective coverings to shield the coils from dust, moisture, and other contaminants that could compromise their integrity.

Transportation

Securely fasten the coils during transportation to prevent movement and potential damage. Use cushioning materials such as wooden supports or foam padding around the coils to provide additional protection during long-distance transportation.

Common Issues and Solutions in On-Site Welding

Defects in Welds

Several types of defects can occur during the welding of stainless steel coils, and understanding these defects is key to preventing them:

- Porosity: Caused by trapped gas bubbles within the weld metal, leading to reduced strength and integrity. Proper gas shielding and cleaning can help prevent porosity.

- Cracks: These can form due to thermal stresses, incorrect welding parameters, or contamination. Preheating and controlled cooling rates can minimize cracking risks.

- Distortion: Occurs due to uneven heating and cooling, leading to warping of the stainless steel coils. Using proper welding techniques and fixtures can reduce distortion.

Prevention and Correction Methods

Effective prevention and correction methods are essential for ensuring high-quality welds:

- Prevention: Implement thorough pre-welding preparation, including surface cleaning, proper fit-up, and selecting the right welding parameters.

- Correction: For minor defects, methods such as grinding, re-welding, or applying filler material can be used. Severe defects may require cutting out and replacing the affected section.

What Are the Safety Precautions for On-site Welding?

Personal Protective Equipment (PPE)

Welding operations involve various hazards, and proper PPE is essential to protect welders:

- Welding Helmet: Protects the eyes and face from intense light and sparks.

- Gloves: Heat-resistant gloves protect the hands from burns and sparks.

- Clothing: Wear flame-resistant clothing to prevent burns from sparks and molten metal.

- Respiratory Protection: Use appropriate masks or respirators to protect against fumes and gases generated during welding.

Safe Work Practices

Adopting safe work practices minimizes the risk of accidents and injuries:

- Proper Ventilation: Ensure adequate ventilation to disperse fumes and gases.

- Fire Safety: Keep fire extinguishers nearby and ensure the work area is free of flammable materials.

- Training: Conduct regular training sessions for welders on safety protocols and emergency procedures.

- Equipment Maintenance: Regularly inspect and maintain welding equipment to prevent malfunctions and accidents.

Conclusion

On-site welding of stainless steel coils is a viable option when proper equipment, techniques, and environmental controls are in place. By understanding the properties of stainless steel, selecting the appropriate welding method, and adhering to recommended practices, high-quality welds can be achieved. Regular inspection and maintenance of the welded joints ensure their long-term performance and reliability in various applications.

References

- American Welding Society (AWS). (2020). Welding Handbook. 9th Edition.

- Lippold, J.C., Kotecki, D.J. (2005). Welding Metallurgy and Weldability of Stainless Steels. John Wiley & Sons.

- Kou, S. (2003). Welding Metallurgy. 2nd Edition. John Wiley & Sons

Read More: