Introduction

It is not easy to locate the appropriate pipe. Schedule 40 Steel Pipe is strong. This blog assists you in choosing the best one. It also describes PSI, ASTM standards, and fittings. Learn more below.

What is Schedule 40 Steel Pipe?

Schedule 40 steel pipe has 0.154-inch wall thickness. The diameter is 1.5 inches. It can handle 220 PSI pressure. That’s good for water, air, and gas. Steel grade A53 is used.

It has a tensile strength of 60,000 PSI. NPT (National Pipe Thread) standard is followed. That ensures tight connections. They are often 21 feet long. This pipe is suitable for plumbing. The inside area is smooth.

How to Identify Schedule 40 Steel Pipe?

Finding Schedule 40 Steel Pipe is easy and exciting! Observe its dimensions, width, and other engravings on it. Now, let’s learn more!

· OD (Outer Diameter)

Schedule 40 PVC pipe thickness in mm is easy to measure. This measures across its widest point. It enables one to determine the size of the pipe. The nominal diameter of a 1 1/4 sch 40 pipe dimensions is helpful. That assists in joining different parts together. It guarantees that pipes connect properly. A ruler or caliper measures the OD.

· Wall Thickness

Sch 40 pipe thickness in mm is important. It indicates the width of the side of the pipe. This assists in determining the strength of the pipe. The thickness of the wall of a 1-inch Schedule 40 Steel Pipe is 0.133 inches. This makes certain that the pipe has the ability to withstand pressure. 2 inch sch 40 pipe dimensions are also relevant.

· Markings

Sch 40s pipe has useful marks. These show important details. These markings include size, wall thickness as well as the manufacturer. It aids in the identification of the pipe, which makes it easy when used correctly. The markings are stamped or printed on the surface of the pipe. This ensures no confusion.

· Pipe Length

3 inch sch 40 pipe dimensions are useful to know. Schedule 40 pipe thickness in inches varies. The lengths can be 10 feet, 20 feet or made to your desired measurements.

It assists in determining how much pipe is required. That is time and material saving. The length should be measured as described accurately.

· Weight

1 1 4 sch 40 pipe dimensions affect weight. It does so depending on its size and length. It assists in identifying how much weight the pipe can hold. A 1-inch pipe has a weight of 1.68 pounds per foot. This assists in transport and deployment.

· Steel Grade

Sch 40 PVC pipe pressure rating is important. This has an impact on its rigidity and functionality. Some of the most commonly used grades include ASTM A53 and A106.

It assists in the selection of the most appropriate pipe. That ensures that it meets the need of the project. Every grade possesses its own characteristics.

· Color Codes

Sch 40 galvanized steel pipe has color codes. These show the type of pipe. Moreover, it assists in quick identification. The codes below utilize different color schemes for different purposes. This ensures correct installation. It is good to have ideas on color codes.

· End Finish

3 4 sch 40 pipe dimensions matter. These influence the manner in which pipes join. Possible finishes include beveled, plain, and threaded. It is used in joining pipes together. That ensures secure connections. All of the finishes have their utility.

· Surface Treatment

Pvc pipe weights vary. These protect the pipe. They include galvanizing, painting, and coating. It helps prevent rust. This also prolongs the life of the pipe. Each treatment has its level of protection. But it is critical to make the correct choice.

· Mill Test

Mill tests are performed on schedule 40 galvanized pipe. These help check the quality of the pipe. Some of the tests are hydrostatic tests, nondestructive tests, and visual tests. It helps to guarantee that the pipe is strong. That meets safety standards. Different aspects are checked by each test.

· ASTM Standards

PVC sch 40 pressure rating is checked. These are to ensure quality and safety. Some of the standards of these pipes are ASTM A53 and A106. It helps in making reliable pipes. That meets industry requirements. Every standard has its own set of rules to be followed.

· ASME Codes

How thick is sch 80 pipe can be found in ASME codes. These provide safety in construction. Some of the codes are ASME B31.1 and B31.3. It contributes to the development of safe systems. That meets regulatory requirements. There are specific rules for each code.

| Parameter | SCH40 Spec | Details |

| OD (Outer Diameter) | 0.5″ – 24″ | Varied by size |

| Wall Thickness | 0.068″ – 0.688″ | Depends on OD |

| Markings | SCH 40, ASTM | Manufacturer, Grade |

| Pipe Length | 21′ – 40′ | Standard lengths |

| Weight | Varies | Per foot, dependent on OD, WT |

| Steel Grade | A53, A106 | Common grades |

| Color Codes | Blue, Green | Indicates specification, grade |

| End Finish | Plain, Beveled | Based on usage |

| Surface Treatment | Galvanized, Black | Corrosion resistance |

| Mill Test | Included | Quality assurance |

| ASTM Standards | A53, A106, A500 | Governing standards |

| ASME Codes | B31.1, B31.3 | Applicable codes |

Table on SCH40!

Why is Schedule 40 Steel Pipe Popular in Construction?

Schedule 40 Steel Pipe is used widely in construction projects for its strength, durability and flexibility. This pipe has a lot of cool stuff. Let’s explore them!

· Strength

The thickness of the wall of the pipe is 0.154 inches. 1.5 schedule 40 steel pipe dimensions help in measurements. Schedule 40 Steel Pipe is durable. It handles high pressures. They support big buildings.

Stainless steel piping pressure rating matters for safety. This pipe has a tensile strength of 60,000 psi. The materials chromium and molybdenum are what make it hard. Chengjiu Metal makes strong pipes.

It measures 21 feet in length. Pipe sch 40 wall thickness is ideal. ASTM A53 requirements are fulfilled.

· Durability

They work with 6 inch schedule 40 steel pipe because it is reliable. It handles impacts well. The yield strength of this pipe is 35,000 psi. This is due to the fact that the coating shields the metal from rust.

The carbon content of the material is 0.3%. Chengjiu Metal’s pipes stay strong. 2 inch schedule 40 pipe dimensions help construction. These pipes are 2 inches in diameter.

· Versatility

This pipe is very useful indeed. Schedule 40 Steel Pipe used for water lines. 1.5 sch 40 pipe dimensions suit many needs. It also works with gas. They range from 0.5 inch to 24 inches.

The inside is smooth. Easy targets are cutting and welding. Chengjiu Metal’s pipes fit well. 6in sch 40 pipe is common. The pipe suits any want. That helps in building. It’s adaptable.

· Availability

These pipes are relatively easy to locate. It holds schedule 40 steel pipe in its stores. They can be large and small. It meets codes worldwide. It is typically 21 feet long. This helps with compatibility. 1 inch schedule 40 pipe dimensions are in demand. They ship fast. That makes projects quick.

· Corrosion Resistance

Schedule 40 Steel Pipe is not prone to rust. CS pipe schedule 40 resists damage. It also has a zinc coating. This makes it last long. Some of them are meant for use outside only. The zinc layer is 1.8 oz/ft².

That protects well. It handles chemicals too. These pipes are robust in places that are not so good. Chengjiu Metal’s pipes resist rust. The thickness of pipe schedule 40 does matter. It meets ANSI standards.

· Pressure Rating

This pipe is strong under pressure. Schedule 40 Steel Pipe has a pressure rating of up to 2,100 psi. They utilize it in hydraulic systems. This is the thickness of the wall: 0.154 inches.

Sch 40 pipe pressure rating is high. This prevents it from leaking. The burst pressure is 8000 psi. Schedule 40 psi rating is tested. That makes it safe. It’s tested for quality. They trust this pipe.

· Weldability

Schedule 40 Steel Pipe is highly weldable. 3 inch schedule 40 pipe dimensions are useful. It integrates with conventional approaches. The carbon is 0.3%. They weld it on-site.

This makes connections strong. The pipes are designed to meet AWS D1.1 requirements. 2.5 schedule 40 pipe dimensions help measurements. That avoids weak spots. They employ several welding methods. Chengjiu Metal’s pipes are easy to weld. Builders are assisted by this pipe’s weldability.

· Cost-Effectiveness

This pipe saves money. Schedule 40 Steel Pipe is also affordable in terms of cost. It lasts long. 6 inch schedule 40 pipe dimensions help in planning. They need less fixing.

A lot of the pipes are made. That keeps prices low. It’s simple to install. This saves on work. They are recyclable. Chengjiu Metal’s pipes are affordable. This helps with costs. The pipes are quite reasonable indeed.

· Ease of Installation

This pipe is very easy to install. Schedule 40 Steel Pipe is lightweight. This makes handling easy. It is smooth. 3/4 schedule 40 pipe dimensions help fit. The ends are threaded.

This helps connect. They do saw it to size. It needs simple tools. That speeds up work. Chengjiu Metal’s pipes install fast. The pipes are marked. 2-1/2 schedule 40 pipe fits many uses. They install it fast.

· Fire Resistance

Schedule 40 Steel Pipe does not burn. It handles high heat. 2 inch sch 40 is useful in fire sprinklers. Melting point is 2,500°F. This keeps buildings safe. It has been established that the pipe complies with the NFPA requirements. It does not produce foul smells.

What are the Key Applications of Schedule 40 Steel Pipe?

Schedule 40 Steel Pipe is used in various applications including in pipelines for water, gas and other services. It is helpful to us in day-to-day activities. Let’s find out how!

· Plumbing

In homes, water passes through pipes. What gauge is schedule 40 pipe? 4 inch pipe schedule 40 works under 200 PSI pressure. These pipes are 1.5 inches big. They can be as long as 10 feet.

It connects to joints and connectors. This makes it strong. These pipes facilitate the movement of the water. That’s important for homes. They are resistant to rusting and that is what makes them durable. Plumbing needs reliable pipes.

· Gas Lines

Natural gas reaches the people’s homes through pipelines. These pipes carry pressure of 300 PSI. Schedule 40 2 inch pipe is 2 inches wide and measures 12 feet in length. It connects to valves.

This keeps gas flowing. They handle high heat. That makes them safe. The pipes are equally strong and rigid. Each one stops leaks. They fit tight.

· HVAC Systems

Air flows in ducts in the HVAC systems. Sch 40 aluminum pipe has pressure rating of up to 250 PSI. These pipes are 3 inches wide. 3 inch sch 40 pipe can reach 20 feet in length. It connects to fittings.

This means that fresh air can circulate through it. They do not undergo rust and can withstand heat. That helps heating systems.

· Fencing

Fences use strong pipes. Sch 40 pvc pressure rating of 100 PSI is good. Sch 40 carbon steel pipe comes 1 inch wide. They can be up to 8 feet in length. It connects to posts. This makes fences sturdy. They resist rust. That helps them last. The pipes handle weather. They keep fences strong.

· Scaffolding

These are pipes used in the construction of the scaffolding by workers. 4 inch sch 40 pipe pressure rating is 400 PSI. These are 4 inch pipes. 4in sch 40 pipe can be up to 15 feet long.

It connects to clamps. This supports weight. One more benefit is that the pipes are very resilient and cannot be easily bent. That keeps scaffolding stable.

· Fire Sprinklers

Sprinklers employ pipes in order to project water. These pipes are designed to withstand up to 350 PSI pressure. Schedule 40 stainless pipe is 2.5 inches wide. They can be up to 12 feet long. It connects to nozzles. This ensures water flow. They do not corrode easily and thus are strong. This makes them convenient especially during a disaster.

· Electrical Conduits

Wires pass through conduits to be safe. Sch40 pipe works at 150 PSI pressure. 1 sch 40 pipe dimensions is 1.5 inch wide. They can be ten feet long. It protects wires. This ensures safety. The pipes resist damage.

· Mechanical Systems

In machines, pipes are required for components that must move. Sch 40 pipe has pressure rating up to 250 PSI. 10 inch schedule 40 pipe are 3 inches in diameter.

Schedule 40 1 1/4 pipe can be as large as twenty feet in length. It connects to pumps. This ensures flow. The pipes have antirust properties and are heat resistant.

What Materials are Used in Schedule 40 Steel Pipe?

Schedule 40 Steel Pipe is made up of various materials such as the carbon steel and stainless steel. Every type has its characteristics. Great! Let’s discover what makes them stand out!

· Carbon Steel

This makes Schedule 40 Steel Pipe very strong. This pipe has a wall thickness of 0.154”. The outer diameter of the pipe is 2.067”. They use carbon for strength. It has a tensile strength of 60000 psi.

It contains 0.3 percent of carbon by weight. The length of this pipe can be 21 feet. What thickness is schedule 40 pipe? It’s the thickness of schedule 40 pipe in mm.

· Stainless Steel

This Schedule 40 Steel Pipe does not corrode. It has a chromium content of 18%. The tensile strength is as high as 75,000 psi. It is used where the environment is clean.

This pipe has an outside diameter of 1.315” and a wall thickness of 0.133”. Schedule 40 psi makes it strong. The 2.5 sch 40 pipe is used too. 1.5 pipe schedule 40 is common.

· Galvanized Steel

Schedule 40 Steel Pipe is galvanized. That prevents rust. 2 sch 40 pipe dimensions are common. Thickness of the coating is 0.4 mm. They use it outdoors. Its outer diameter is 2.375 inches.

This pipe has a wall thickness of 0.154 inches. Galvanized steel pipes have long durability. 3 4 schedule 40 pipe dimensions help too.

· Alloy Steel

It incorporates other metals into Schedule 40 Steel Pipe. This combination makes it powerful. Molybdenum and nickel improve its characteristics. They provide flexibility and rigidity.

Its tensile strength can be as high as 80,000 psi. The diameter of the pipe is 2.067 inches. 2 inch schedule 40 pipe is used a lot.

· Seamless Steel

Schedule 40 Steel Pipe does not contain any welded joints as it is seamless. It is smooth surfaced. The tensile strength is 70,000 psi. They employ it in indispensable operations. Its outer diameter is 3.5”. The wall thickness of this pipe is 0.216”. Sch 40 pipe is strong.

· Welded Steel

This Schedule 40 Steel Pipe comes with a welded seam. The welds are strong. It has a tensile strength of 60,000 psi. It is used in structural projects. The pipe has an outer diameter of 4” and a wall thickness of 0.237”. Sch 40 wall thickness is thick.

· Hot-Dipped Galvanized

Schedule 40 Steel Pipe is submerged in hot zinc. This gives a thick layer. The thickness of the zinc layer is 0.5 mm. It has good anti-corrosion performance. Its outer diameter is 3”. This pipe’s wall thickness is 0.216”. OD of 6 inch pipe is bigger.

· Black Steel

This Schedule 40 Steel Pipe is plain. It lacks a coating. The material is dark. It has a tensile strength of 55,000 psi. They use it for gas lines. This pipe’s outer diameter is 1.5”. The wall thickness of this pipe is 0.145”.

· A53 Grade

It conforms to ASTM A53 specifications on Schedule 40 Steel Pipe. The tensile strength is 58,000 psi. The diameter of the pipe is 2.375 inches. This has the wall thickness of the pipe 0.154 inches.

· A106 Grade

This Schedule 40 Steel Pipe complies with ASTM A106 specifications. It handles high temperatures. Tensile strength is 70,000 psi. It has an outer diameter of 2.5”. The thickness of the wall of this pipe is 0.203”. They use it for boiler tubes, for instance.

· API 5L Grade

It is an API 5L Grade B Schedule 40 Steel Pipe. This ensures quality. The tensile strength is 65,000 psi. Its diameter is 2.875”. The wall thickness of this pipe is 0.276”.

· ASTM Grades

Schedule 40 Steel Pipe meets ASTM requirements. It ensures safety. The tensile strength varies. It can be 1” to 4” in diameter. This wall thickness is 0.133” to 0.237”.

What Standards Govern Schedule 40 Steel Pipe?

Like all products, Schedule 40 Steel Pipe is made in accordance with quality and safety measures. These standards enable pipes to function properly in many places.

| Standard | Material | Diameter (in) | Thickness (in) | Pressure (psi) |

| ASTM A53 | Grade B | 1.0 | 0.133 | 300 |

| ASTM A106 | Carbon Steel | 1.0 | 0.140 | High Pressure |

| ASTM A500 | Cold-formed | 1.5 | Various | Various |

| ASTM A252 | Various Grades | 2.0 | 0.154 | Various |

| ASME B36.10M | Various Materials | Various | Various | Various |

| ASME B36.19M | Stainless Steel | 2.0 | 0.154 | Various |

| API 5L | High Strength | 3.0 | Various | High Pressure |

Table on Standards that Govern Schedule 40 Steel Pipe!

How to Determine the Correct Size of Schedule 40 Steel Pipe?

Selecting the correct size Schedule 40 Steel Pipe is crucial. After that, we can measure its diameter, thickness, as well as its weight in order to ensure that it fits as it should.

· Nominal Diameter

Schedule 40 Steel Pipe also has a specific nominal diameter. This measures the width. It is expressed in inches, such as 2” or 4”. NPS means Nominal Pipe Size. That size gives an idea of the diameter in question. The inside diameter is not the same with the nominal diameter.

They generally make use of pipes with a nominal diameter in construction. Fitting parts require the nominal diameter therefore it is very important. Each pipe’s nominal size defines its compatibility. Schedule 40 piping come with standard sizes.

· Inside Diameter

The inside diameter of schedule 40 steel pipe must be considered. This gauges its internal dimensions. It affects flow. They measure it in inches. It determines the rate of flow of water through it. Each size has its own inside diameter. Schedule 40 pipe ID affects performance.

· Outside Diameter

The outside diameter of the schedule 40 steel pipes does matter. It is the width outside. They use this measurement for fittings. It is different from inside diameter. The outside diameter is constant for each pipe size. As the name suggests, OD is an abbreviation for outside diameter.

This size is pivotal for connections. It uses inches. 2 3/8 outside diameter pipe is common. Pipes must fit together properly.

· Wall Thickness

Schedule 40 Steel Pipe has certain thickness of its walls. This determines the thickness of the pipe wall. It affects strength. Engineers call it “WT”. They employ such a fraction as for example 0.237 inches.

That ensures durability. Each size is a certain thickness. This affects weight. The thicker walls of the pipe bear more loads. Pipe schedule 40 weight varies with thickness.

· Pipe Length

Schedule 40 Steel Pipe is available in different sizes in terms of length. It specifies the length of the pipe. They use feet, such as 10 feet or 20 feet. This matters for installation. Every length of pipe corresponds to specific projects. Here, the abbreviation PL is an acronym for pipe length. It affects transportation.

It is also important to point out that longer pipes require more careful handling. Pipe 3 inch sch 40 is often long.

· Weight per Foot

It is vital to consider the weight per foot of Schedule 40 Steel Pipe. This refers to the weight of the pipe per foot. It uses pounds, like 2.2 lbs/ft. This affects handling. Engineers call it “WPF”.

They use this to calculate total weight. That assists in transport planning. Every size is known to have a specific weight for each foot. Weight of sch 40 steel pipe is crucial.

· Pressure Rating

Schedule 40 Steel Pipe has a certain pressure containing capacity. This measures the pressure it is capable of taking. It uses psi, such as 400 psi. They call it “PR”. This ensures safety.

The pipes are divided according to size and each of them has a specific rating. This impacts its use in various systems. Accurate ratings prevent accidents. 6 schedule 40 pipe weight affects rating.

· Flow Rate

There are many factors to consider with Schedule 40 Steel Pipe, and the flow rate is one of them. This describes the rate of flow of the fluids. It can use GPM, such as 50 GPM. Engineers call it “FR”.

This affects system performance. All the sizes have their restricted flow rates. That ensures efficient use.

In planning, flow rates can be planned or estimated to be accurate. They perform calculations in terms of pipe size. 1 inch sch 40 pipe has a specific flow rate. 3/4 pipe schedule 40 also affects flow.

· System Compatibility

Schedule 40 Steel Pipe must be compatible with the other systems in the building. This way it can fit in the other parts in the mechanism. They verify such things as sizes, such as 2” NPS Impact on compatibility influences installation Engineers refer to it as SC.

This means that each system requires matching components. This is important since appropriate measurements will be taken to ensure that the garments fit perfectly. That prevents leaks.

· Pipe Fittings

Schedule 40 Steel Pipe requires numerous pipe fittings. They connect pipes. Fittings can be of different types. Every fitting corresponds to certain sizes only.

They employ designs such as 3” OD They also utilize fittings such as elbows, tees as well as couplings Engineers refer to them as PF. Conducive fittings provide the right connection.

Schedule 40 metal pipe uses fittings. 1.5 sch 40 pipe needs correct fittings. 3/4 sch 40 pipe also needs fittings. 3in stainless steel pipe uses fittings. Sch 40 6 pipe weight is a factor.

| Parameter | Nominal Diameter | Inside Diameter | Outside Diameter | Wall Thickness | Weight per Foot | Pressure Rating |

| 1/2 inch | 0.50″ | 0.622″ | 0.840″ | 0.109″ | 0.85 lbs/ft | 400 psi |

| 3/4 inch | 0.75″ | 0.824″ | 1.050″ | 0.113″ | 1.13 lbs/ft | 400 psi |

| 1 inch | 1.00″ | 1.049″ | 1.315″ | 0.133″ | 1.68 lbs/ft | 400 psi |

| 1 1/4 inch | 1.25″ | 1.380″ | 1.660″ | 0.140″ | 2.27 lbs/ft | 370 psi |

| 1 1/2 inch | 1.50″ | 1.610″ | 1.900″ | 0.145″ | 2.72 lbs/ft | 330 psi |

| 2 inch | 2.00″ | 2.067″ | 2.375″ | 0.154″ | 3.65 lbs/ft | 280 psi |

| 3 inch | 3.00″ | 3.068″ | 3.500″ | 0.216″ | 7.58 lbs/ft | 260 psi |

Table on the Correct Size of Schedule 40 Steel Pipe!

What are the Installation Requirements for Schedule 40 Steel Pipe?

When it comes to placing Schedule 40 Steel Pipe, the materials have to be accurately cut, threaded, and fixed. This assists the pipe to work right. Let’s learn the steps!

· Cutting

Cutting requires the use of a chop saw. It contains a blade size of 14 inches. It can even slice through 2-inch pipes. That vice grips pipes firmly. Coolant is used to cool the blade. The invention of the sharp blade enables the students to make clean cuts. They use safety goggles. It must be a clean cut.

· Threading

Threading requires a pipe threader. The machine cuts threads. It uses dies for half inch pipe. Threading oil acts as a coolant for the dies. Threads make tight connections. They stop leaks. The process is quick. It takes minutes. It prepares 2 in steel pipe schedule 40 for the connection of fittings.

· Welding

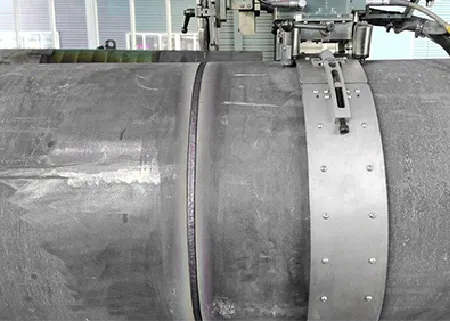

Welding employs a MIG welder. The machine joins industrial steam pipe. The wire of 0.035 inch helps in the welding process. It uses argon gas. This gas also protects the weld. The heat has to be managed. The welder is responsible for creating a solid seam. They prevent warping. Welding guarantees joint integrity of schedule 40 pipe.

· Fitting

Fitting uses various fittings. These are elbows, tees and couplings. A pipe wrench is used to tighten them. It uses Teflon tape. This tape seals joints. The fittings align black schedule 40 pipe.

· Jointing

Bolting requires couplers and gaskets. These join pipe sections. The gaskets seal joints. They stop leaks. It needs alignment tools. The tools contribute to maintaining straight 1 in schedule 40 steel pipe.

· Alignment

Alignment uses a tool called the laser level. The level makes for straight steel schedule 40 pipe. Clamps hold pipes. This requires a spirit level. The level checks position. Alignment keeps flow smooth.

· Securing

Securing uses pipe hangers. These support 5 8 od pipe. Hangers are fixed on walls by means of anchor bolts. The process employs the use of a drill. This drill provides holes for bolting.

· Inspection

Inspection uses an endoscope. The tool inspects the interior of the pipes. It requires a monitor. This monitor indicates the condition of the 3 4 sch 40 steel pipe. A beam of light from a torch shines through the pipe. They find defects.

· Testing

Testing employs a pressure gauge. The gauge measures pressure. Water fills the pipe. It requires a pump in the process. This pump increases pressure. They guarantee sch 80 pressure rating of steel pipe sch 40 to withstand stress. Testing prevents failures.

How to Maintain Schedule 40 Steel Pipe?

Schedule 40 Steel Pipe helps retain its strength and safety by maintaining it. In this way it lasts long and performs well if it is checked and cleaned often!

· Regular Inspections

Maintenance such as inspecting the pipes helps in enhancing their strength. Examine the Schedule 40 Steel Pipe. It should have no crack at all. This pipe has to be strong and resistant.

Verify that its OD is 1.5 inches. As for the thickness, you can measure at 0.145 inches. The gauge assists with this. They should be secure. Bolts must be tight. Pipe weight per foot is important to check.

· Cleaning

Schedule 40 Steel Pipe must be cleaned with equal care. Use only a brush and clean water. Dissolve 5% detergent in it. This solution cleans well. Wipe each pipe with a soft cloth. They must stay shiny. Black pipe dimensions are crucial. Sealing end caps to prevent dirt from getting in.

It does help pipes remain clean. It is therefore important to work in a well ventilated area at all times. This prevents moisture buildup.

· Lubrication

Make it a habit to lubricate the Schedule 40 Steel Pipe. Use a grease gun. The lubricant should be ISO VG 150. Apply it evenly. This helps reduce friction. Monthly checks are recommended.

Bearings should move smoothly. Avoid over-lubricating. It can cause problems. Lubrication helps pipes in their functioning. Steel pipe diameters matter too. Thus, they are more durable in their functioning or long-lasting in their actions.

· Corrosion Protection

Make sure the Schedule 40 Steel Pipe does not get rusty. Use a zinc coating. Apply a layer of the material that is 0.5 mils thick. It also plays a protective role. Inspect pipes for scratches.

These can cause rust. Pipes should be stored in areas devoid of moisture. They should be safe. For absorbing moisture, embrace the silica gel packs. That keeps pipes rust-free. Pipe chart size should be consulted.

· Leak Detection

Examine the Schedule 40 Steel Pipe for signs of leakage. Use a hydrostatic test. It uses water at 150 pounds per square inch. This finds cracks. Inspect joints carefully. They can leak. Look for water droplets. That shows a problem. Repair leaks quickly. Pipe weight chart helps understand specifications.

· Pressure Testing

Check the Schedule 40 Steel Pipe for pressure. Use a pressure test. It checks strength at 200 psi. Inspect valves and seals. These must be tight. Take drops if possible in the gauge. That shows leaks. Fix any issues quickly. Pipe dims should be monitored.

· Painting

Paint the schedule 40 steel pipe well. Use a primer first. It helps paint stick. Choose rust-proof paint. Apply a thin coat. This protects pipes. Often use a brush or a sprayer application technique.

They suggest two coats. Let each coat dry. Inspect for even coverage. That makes certain no part of the body is left out. Size of schedule 40 pipe is essential.

· Rust Removal

Clean the Schedule 40 Steel Pipe for any form of rust. Use a wire brush. It scrapes rust off. Use a rust remover that contains 10% phosphoric acid. This dissolves rust. Rinse with water. Dry the pipe well.

Inspect the surface. They recommend regular checks. It is preferable to wear gloves and goggles all the time. That protects you. Rust removal helps in maintaining the purity of the pipes. 6 inch schedule 40 pipe requires careful attention.

· Coating Maintenance

It will be of paramount importance to keep up with the Schedule 40 Steel Pipe coatings. Inspect regularly for chips. Use a touch-up kit. It consists of brush and paint. Apply to damaged areas. Let it dry. Check thickness. This should be 1-2 mils. 10 inch pipe needs regular maintenance.

· Repairing Damages

Repair the damages on Schedule 40 Steel Pipe. Check for cracks. Use a pipe cutter. Cut damaged sections out. Replace with new pipe. It should match size.

To connect the parts, a coupling is recommended. These keep connections tight. Test for leaks. That ensures repair. They maintain the strength of the pipe. 3 schedule 40 pipe and 1 schedule 40 pipe are often replaced.

What are the Common Problems with Schedule 40 Steel Pipe?

Schedule 40 Steel Pipe can be subjected to issues such as rusting and leakage. These are issues which require immediate solutions. So let’s try to learn how to find them and fix them!

· Corrosion

The 4 sch 40 pipe is prone to rusting. This 1 1/2 schedule 40 pipe becomes damaged as time passes. It occurs due to the oxidation process. The Fe of the pipe reacts with O₂. This causes rust, Fe₂O₃.

It precipitates on the surface. The rust flakes off. They expose the pipe. It then corrodes more. This makes it weak. The sch 40 steel pipe can break. That is why such checks are necessary.

· Leaks

Schedule 40 stainless steel pipe tends to leak. This can happen at 150 PSI. The joints of the pipe may rupture. They enable water to drain. It can take a lot of water to do and, therefore, is not efficient in its use of water resources. They also create damage. The leaks cause the pipe weight to rust. They need quick fixes. That stops more problems. This is how often they are discovered during the check.

· Cracks

The 3 sch 40 pipe can crack. This happens at 200°F. These cracks start small. They increase in size as time passes by. They show up at stress areas. This includes bends or joints. They also allowed water to drain out. This one makes the pipe fail.

· Blockages

Schedule 40 pipe pressure rating is not immune to blockages. This is the case with accumulation of debris. The steel pipe sizes and dimensions of 1/2” get clogged. It prevents the flow of water. This makes pressure rise. The pipe might burst. They need regular cleaning. This makes water flow well. That stops blockages.

· Erosion

The sch 10 pipe thickness undergoes erosion. This wears it down. It occurs at flow rates greater than 3 GPM. The pipe gets weak. That can cause leaks. Avulsion also alters flow patterns. In addition, erosion causes changes in flow paths. Regular checks spot erosion.

· Pressure Loss

The weight of pipe chart shows pressure loss. This is achieved at a flow rate of 10 feet per second. The pressure decreases along the pipe. It affects water delivery. This makes appliances work poorly. It also leads to noise production due to the pressure loss. This affects comfort. That needs fixing.

· Joint Failures

The stainless steel pipe sizes chart shows joint failures. This occurs at 100 PSI. The joints can break. It causes leaks. The pipe’s connections weaken. This lets water escape. The joints need checking. That helps avoid breaks. Small constant repairs maintain joints healthy.

· Bending

It is noteworthy to note that sch pipe chart can bend. This occurs when the weight is less than 500 lbs. of force. It changes shape. The bends make porous areas. This can cause leaks. The pipe’s alignment shifts. This affects water flow. Bending needs a fixing. Daily inspections identify curves at an early stage.

· Fatigue

The schedule 40 pipe undergoes fatigue. This makes it weak in the long run. It occurs when constant usage is made of it. The material of the pipe gets fatigued. This makes it crack.

That can cause leaks. Fatigue needs watching. Such checks help to identify early signs. This assists in fixing it as soon as possible.

· Wear and Tear

26.7 kg to lbs calculations show wear and tear. This occurs with daily usage. There is the destruction of the pipe surface. It loses strength. This can cause leaks. Regular checks spot damage. They assist in correcting it early. This helps to maintain the strength of the pipe.

· Scaling

The steel pipe weight causes scaling problems. This is well illustrated by case of mineral buildup. It blocks water flow. The diameter of the pipe decreases to 3/4”. This increases pressure. Scaling needs a proper cleaning.

· Mechanical Damage

The schedule 40 stainless steel pipe undergoes mechanical damage. This happens from impacts. It can dent or crack. The thickness of the pipe reduces to 1”. This causes leaks. Regular checks find damage.

How to Source Quality Schedule 40 Steel Pipe?

Schedule 40 Steel Pipe the right way means procuring it from a reliable steel pipe supplier. Thus, by checking for the certification and reading the reviews, we are in a position of making the best choice.

· Supplier Verification

Discuss if the Schedule 40 Steel Pipe supplier is good. Wall thickness of this pipe is 0.154 inch. The diameter of the pipe is 1.5 inch. ASTM A53 and A106 must be followed by it.

They check the yield strength which is 35000 psi. That makes it strong. Inspect each batch. Ensure that the supplier complies with the ISO 9001 standard. It’s important for quality. Schedule 40 pipes have different ratings depending on their pressure. Use ASME B36.10M.

· Certification Check

Obtain certifications for Schedule 40 Steel Pipe. This type of pipe requires the ASTM A106 standards. It should have tensile strength of 60,000 psi. They check this. Which helps to ensure it is strong.

Nonetheless, quality requires ISO 9001. For resistance to rust use NACE MR0175. Review these with third party inspectors.

· Material Testing

Perform tests on the 40 Steel Pipe materials. It’s important for strength. The yield strength of the pipe is 35 ksi. They sample it to be certain. This includes hardness tests such as Rockwell hardness.

This is in reference to the rule of ASTM E18. That keeps quality. Charpy tests check toughness. Test chemicals with ASTM E415. Use spectrometry. It finds exact metals. Tests spot problems. This keeps pipes reliable. Perform X-rays for non-destructive examinations. It checks inside.

· Price Comparison

Check out prices for Schedule 40 Steel Pipe. This pipe is $3.50 per foot. Prices change by supplier. They give bulk discounts. It lowers costs. Pipe size affects the price change. ASME B36.10M assists you in comparing sizes. Utilize it for equal charges. ASTM A53 pipes have higher prices as compared to A106.

· Stock Availability

Verify if Schedule 40 Steel Pipe is readily available. It matters for projects. Some of these types are available in standard dimensions such as 1.5 inches and 2 inches. Ask suppliers.

Some show real-time stock. It tells current levels. Large orders could take a while. Use FIFO for stock. It keeps pipes fresh.

· Delivery Time

Learn more about the Delivery Time for Schedule 40 Steel Pipe. It’s key for projects. This pipe ordinarily takes 5 days to ship. They use freight carriers. That’s quick.

Find out the supplier’s transportation methods. Some are quicker, the others are cheaper. Distance matters. Farther places take longer. Track shipments by using tracking. The mass of the pipe influences the speed.

· Customer Reviews

Check the feedback on Schedule 40 Steel Pipe. This assists in finding out whether it is good. They give different views. This comprises of quality and strength. Read about customer feedback on the website of the supplier. Use other sites for fear views. Only good reviews imply good service in the hotel.

Negative reviews are signs of issues. This helps decide. Reviews mention ASTM standards. That’s important. Read recent reviews. It helps choose right.

· Supplier Experience

Ensure that the supplier has information on Schedule 40 Steel Pipe. This shows their skill. They have to understand the work. This pipe calls for precise set of rules. They should follow ASTM A53. Established suppliers are capable of handling large orders. They keep quality steady.

Check samples of their work which they have completed in the past. It shows success. The one way supplier experience affects trust. See what skills they have and what tools they use.

· Warranty Terms

Consult the warranty pertaining to Schedule 40 Steel Pipe. It’s needed for safety. This pipe may come with a one-year warranty in most cases. They cover defects.

That includes material issues. Check what’s covered. It should say replacement terms. Warranties vary by supplier. It’s important to know. Some terms exclude things. Confirm all details. Warranty gives protection.

How to Ensure Longevity of Schedule 40 Steel Pipe?

For Schedule 40 Steel Pipe to have a long lasting life, it has to be installed and utilized in the correct manner. Preservation of it makes it remain strong. Let’s see how!

· Proper Installation

Use Schedule 40 Steel Pipe with secure fittings, valves and gaskets. Make sure the tubes have a diameter of 40mm and a wall thickness of 6mm. This calls for torque precision, commonly 40 N⋅m.

Apply Teflon tape on threads. They help stop leaks. Supports should be placed every 3 meters while brackets should be fastened at the bends. Make certain that all joints are properly secured. Avoid bending. Check for misalignment. It can cause problems.

· Regular Maintenance

Look for cracks and rust on Schedule 40 Steel Pipe. Bolts have to be tightened with a 10 mm wrench. Check the pressure gauge. It should say 50 to 70 psi. Sand the outside with 100-grit sandpaper.

Wash the interior with a solution of 5% vinegar. Replace gaskets. Check that support brackets are secure. Use anti-corrosion spray. Verify all connections. They must be secure.

· Corrosion Protection

Paint Schedule 40 Steel Pipe’s surface with zinc-rich primer. Make sure that the layer has a thickness of 100 micrometers. Apply an epoxy coating of 250 microns to increase thickness. Inspect every 6 months.

Check for rust spots. They have to be sanded off. It is recommended to use a brush in order to apply a new coat. It helps stop moisture.

· Pressure Management

Use a gauge to check the pressure of Schedule 40 Steel Pipe. It should not be more than 150 psi. Install a relief valve. Make it to be released at a pressure of 140 psi. Ensure the valve works. Check monthly. Maintain pressure with a diaphragm pump. Avoid sudden pressure changes. Inspect for bulges.

· Load Distribution

Spread load over Schedule 40 Steel Pipe. Install brackets every three meters. Do not put too many loads in one place. Mount equipment on different stands. Make sure that brackets can withstand up to 200 kg. Install load spreaders at anchors. Check for sagging. They show overloading. Balance the load. It stops stress points.

· Avoiding Chemical Exposure

Avoid exposing Schedule 40 Steel Pipe to chemicals such as hydrochloric acid. Use barriers if needed. Store the chemicals separately. Ensure good ventilation. Use chemical-resistant paint. Coating should be inspected every 6 months. Check for damage. It should be repaired as soon as possible.

· Protective Coating

Cover Schedule 40 Steel Pipe with a 300 μm thick polyurethane layer. Make use of a spray gun because it provides a uniform coat. Use a gauge to inspect the thickness. Reapply every 5 years. Inspect for chips. They have to be addressed as soon as possible. Keep the pipe clean. Avoid harsh chemicals. They damage the coating.

· Inspections

Inspect Schedule 40 Steel Pipe frequently. For cracks, use a flashlight. Inspect joints. They should be tight. Check support brackets. They must be firm. Use a moisture meter. It should be below 15%. Inspect the coating. Ensure no peeling. Check the pressure gauge. It must be normal. Always use a wrench for loose bolts.

· Timely Repairs

Fix Schedule 40 Steel Pipe as soon as possible. Replace broken fittings. A 15 mm wrench should be used. Tighten connections. Apply sealant on threads. They stop leaks. Replace gaskets. Inspect for rust. Sand off the spots. Apply zinc-rich primer. Ensure proper alignment.

· Use of Quality Materials

Select Schedule 40 Steel Pipe of the highest quality. Make sure it complies with ASTM requirements. Use grade A106-B steel. Inspect for defects. Check wall thickness. It should be 6 mm. Use stainless steel fittings. They resist corrosion. Ensure materials are certified. Teflon tape should be used on threads.

· Correct Sizing

It should be ensured that Schedule 40 Steel Pipe diameter corresponds with the system. For normal usage, use ⌀40 mm. Check wall thickness. It should be 6 mm. Length should be measured accurately. Saw using a pipe cutter. Avoid saws. They cause rough edges. Use correct fittings.

Conclusion

Selecting Schedule 40 Steel Pipe is not difficult anymore. Follow ASTM rules. For more information visit ALLOYXPERT. Buy the best pipes and fittings you can get there.