Table of Contents

Introduction

Strength vs Stiffness vs Hardness are three fundamental mechanical properties that define how materials respond to external forces. Each has distinct characteristics, testing methods, and applications, but they are also interrelated. Understanding these differences helps engineers and manufacturers choose the right materials for specific applications.

What Is Strength?

Strength is a material’s ability to resist plastic deformation and failure under an applied force. It determines how much stress a material can endure before permanent deformation or fracture occurs.

There are several types of strength:

- Yield Strength – The maximum stress a material can withstand before plastic deformation begins.

- Tensile Strength – The highest stress a material can endure before breaking under tension.

- Compressive Strength – The ability of a material to resist forces that push it together.

- Bending Strength – The capacity of a material to resist bending forces.

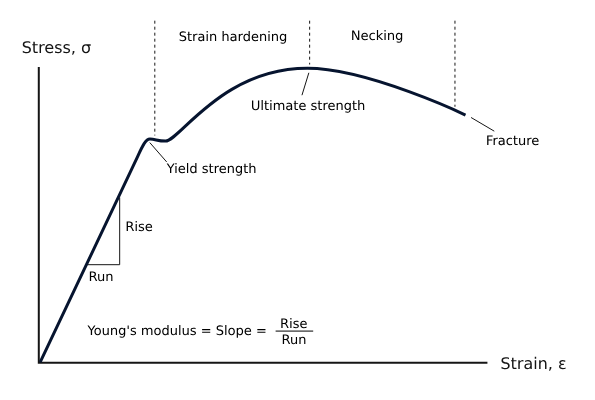

Strength is commonly tested using a tensile test, where a sample is stretched until it fractures. The results are measured in Pascals (Pa), indicating how much stress the material can handle before failure.

Strength is critical in load-bearing structures, mechanical components, and industrial applications that require materials to withstand high stresses without breaking.

What Is Stiffness?

Stiffness is a material’s ability to resist elastic deformation when subjected to a force. It determines how much a material bends or stretches under load before returning to its original shape when the force is removed.

Stiffness is assessed by applying force and measuring deformation. It depends on the material’s elastic modulus, which quantifies its resistance to elastic deformation.

Stiffness is crucial in mechanical and structural engineering. Components like machine spindles, support beams, and high-precision equipment need high stiffness to minimize deformation and ensure stability.

What Is Hardness?

Hardness is a material’s ability to resist indentation, scratching, or penetration by a harder object. It reflects a material’s wear resistance and durability.

There are several hardness testing methods:

- Brinell Hardness (HB) – Uses a steel or tungsten carbide ball to indent the material.

- Rockwell Hardness (HR) – Measures penetration depth using different indenters.

- Vickers Hardness (HV) – Uses a diamond pyramid indenter for precise testing.

Hardness determines a material’s resistance to wear, abrasion, and surface deformation. It is essential in applications like cutting tools, bearings, and wear-resistant components.

Strength vs Stiffness vs Hardness: Key Differences Explained

Definitional Differences

- Strength measures a material’s resistance to plastic deformation and fracture.

- Stiffness focuses on how much a material deforms elastically under force.

- Hardness evaluates how well a material resists surface indentation and wear.

Testing Method Differences

- Strength is measured using a tensile test, which evaluates how a material deforms and fractures under tension.

- Stiffness is assessed by applying a force and measuring deformation, often using Hooke’s Law and elastic modulus calculations.

- Hardness is tested by pressing an indenter into the material’s surface and measuring the depth or size of the indentation.

Application Differences

- Strength is critical in structural materials and load-bearing components.

- Stiffness is important in precision applications where maintaining shape under load is essential.

- Hardness is crucial for wear resistance in cutting tools, coatings, and high-contact surfaces.

Summary Table of Strength vs Stiffness vs Hardness

| Property | Definition | Testing Method | Application |

| Strength | Resistance to plastic deformation and failure | Tensile test | Load-bearing structures, mechanical components |

| Stiffness | Resistance to elastic deformation | Elastic modulus test | Precision parts, structural components |

| Hardness | Resistance to indentation and wear | Brinell, Rockwell, Vickers tests | Cutting tools, wear-resistant surfaces |

How Strength vs Stiffness vs Hardness Relate to Each Other

Hardness and Strength

Harder materials generally have higher strength, as both properties relate to resistance against external forces. However, a material can be hard but brittle, meaning it may not necessarily have high overall strength.

Stiffness and Strength

Stiffness and strength often go hand in hand, but they do not always correlate. Some stiff materials can be weak under high force, while some strong materials may be flexible.

Comprehensive Material Selection

Engineers consider all three properties when selecting materials for different applications. For example, machine tools require high hardness for durability, while structural beams require both strength and stiffness for stability.

Conclusion

Strength vs Stiffness vs Hardness is a crucial topic in material science and engineering. Strength focuses on resistance to plastic deformation and failure, stiffness measures resistance to elastic deformation, and hardness evaluates wear resistance. Understanding these differences helps engineers select the right materials for different applications, ensuring optimal performance, durability, and reliability.

Want to make the right material choice for your next project? Explore our expert recommendations and get insights tailored to your needs. Contact Alloyxpert today!

Read More:

Overheating in Metal Heat Treatment: Causes & Prevention

15 Common Heat Treatment Misconceptions Debunked

Steel Naming Convention Explained for Easy Material Selection