Are there different types of steel? Do you know that each kind of steel has its specific purpose? Carbon steel, for instance, is known to have a multitude of applications. Whether it’s in construction, manufacturing, or automotive, Carbon steel is the ultimate option. Carry on reading to discover why.

This post is an essential read if you’re a metal enthusiast, engineer, or someone curious about carbon steel. If you prioritize attributes like durability, carbon steel stands from other plain steel. Get to know in-depth 20 must-know facts about Carbon Steel.

What Is Carbon Steel?

Carbon steel is quite intriguing. It’s a blend of iron and carbon, as the name implies. As for its composition, carbon steel typically contains anywhere from 0.12 to 2.00 percent carbon. It has different options ranging from low to medium and high carbon steel.

Most importantly, Carbon Steel has countless advantages over traditional steel. Be it durability, strength, or cost-effectiveness!

20 Must-Know Facts About Carbon Steel

Let’s discover the facts about carbon steel you didn’t know about! So first, let’s start with an insight into the composition.

Composition Insight

Note that higher carbon content correlates with improved strength in carbon steel. As stated, Carbon steel is primarily composed of iron and carbon. Yet, let’s break down the components of Carbon Steel. The principal elements found in Carbon steel are mainly:

- Carbon

- Manganese

- Silicon

- Sulfur and Phosphorus

- Copper

We will dive deep into each of these components later in this post.

Historical significance

Carbon steel has a history that dates back to ancient times and extends well beyond that era.

We don’t know precisely when or how the discovery of steel was made. Some say that carbon steel originated in China around 1,800 B.C.E.

It was initially employed in the production of tools and weaponry. The Chinese achieved this by adding charcoal or carbon to molten iron ore. Thus, it creates a stronger and more resilient material than pure iron alone.

During the Middle Ages, carbon steel production increased in Europe. Adding to this is the growth of the ironworking industry. Skilled artisans learned to control carbon content, crafting superior weapons for battle.

The Industrial Revolution shaped the history of carbon steel.

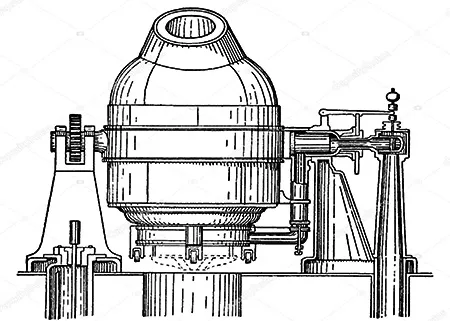

The introduction of the Bessemer process in the 1800s revolutionized steel production. Thus, it became faster, more cost-effective, and of higher quality. It expanded to drive forward global economic and technological growth.

Carbon steel continues to be an indispensable material in various industries. That goes back to its strength, durability, resilience, and versatility.

Cost-effectiveness

Carbon steel is widely recognized for its affordability. This is primarily due to its lower manufacturing costs compared to other types of steel.

Its cost-effectiveness is due to factors such as plenty of raw materials. Additionally, the widespread market availability contributes to its affordability.

Unlike plain steel, Carbon steel can be produced efficiently and on a large scale. Likewise, this keeps production costs down.

All in all, it combines the advantages of carbon steel to make it an affordable choice. Thus, it is suitable for industries like construction, infrastructure, automotive, and machinery manufacturing.

Appearance

Carbon steel, a foundation material in many industries, has an appealing visual appearance. It exhibits inherent strength and versatility.

Metallic shine: Carbon steel has a distinctive metallic appearance. It, therefore, gives a warm glow to its appearance.

Colors: The colors vary from dark gray to silver, depending on factors such as finish and texture.

Texture: The texture of carbon steel is diverse, either smooth and refined or smooth and matte. It depends on the process and treatment.

Common Alloys

Different alloys are added to carbon steel to change its properties for specific applications and uses.

Manganese: Manganese helps improve hardness, strength, and corrosion resistance. It facilitates the formation of refined grains during the cooling process.

Silicon: Silicon aids in the deoxidation phase, which results in more resistance.

Sulfur (S) and Phosphorus (P): They Reduce ductility. So, efforts are being made to minimize their occurrence.

Copper (Cu): Copper provides better corrosion resistance. It works well in areas where corrosion is a concern, such as marine applications.

Brittleness

In carbon steel, brittleness showcases its natural toughness. While we often praise carbon steel for its resilience, carbon can give it an extra edge, especially in specific temperature conditions.

This unique quality highlights the steel’s reliability. As a result, it ensures that it stays solid and sturdy no matter what conditions it faces. Carbon steel achieves strength and flexibility through diligent adjustment of carbon levels.

In addition, precise heat treatments and specialized alloying techniques are used. This meticulous process ensures that carbon steel meets the demands of various applications. All this while maintaining its durability.

Robust Strength and Durability

Strength stands out as a remarkable benefit of Carbon Steel. Hence, it is a top choice for all sorts of industries that demand durability. Its composition gives it that extra hardness and resilience.

And it’s not just strong – carbon steel is tough, too. That means it can take hits and handle sudden stresses without breaking due to its impressive ability to soak up energy.

No wonder carbon steel is a favorite in industries for its winning strength and toughness.

Heat Treatment

Heat treatment is the method that enhances the properties of carbon steel. Let’s discover several processes for heat-treating Carbon steel:

Annealing

During annealing, steel goes through a heat-treatment process to soften it. It implies a series of heating and cooling steps. So, Annealing adjusts the properties of the metal by efficiently modifying its crystalline structure, relieving internal stress.

Quenching

This process requires quickly cooling hot metal using oil or water. As a result, changes in its microstructure increase hardness. Following quenching, tempering is a crucial step to achieve the desired properties.

Tempering

This technique heats it to a specific temperature based on the desired flexibility. Eventually, a portion of the steel’s hardness is removed during tempering. So, toughness and flexibility improve while guaranteeing that the steel maintains its integrity.

Normalizing

Normalizing is a heat-treatment process aiming to unify the microstructure of tiny steel crystals. It builds up overall structural uniformity. This process enhances the excellent stability of the structure. It makes the metal ready for further procedures.

Welding Ease

The ease of welding carbon steel is influenced by its carbon composition. Carbon steel is preferred for its weldability. As a consequence, it is a favored choice in various industries.

Fundamentally, flexibility and malleability play an essential role in its weldability. It makes the joining of components smooth. Furthermore, carbon steel reveals outstanding thermal conductivity. Consequently, it ensures even heat distribution while welding.

All of this is done during welding for consistent and high-quality welds. Additionally, it serves standard welding methods, like arc welding, MIG welding, and TIG welding. That makes it accessible to a broad type of welding professionals.

Versatile Applications

Carbon steel is a flexible metal blend employed in a good many industries. Thus, it is preferred worldwide for diverse applications.

We will go through the most known industries that use Carbon steel:

Construction and Architecture

Owing to its versatility, Carbon steel is preferred in the construction industry. As a consequence of its ease of shaping and ability to resist heavy loads, it’s suitable for applications like skyscrapers, bridges, and large buildings.

Automotive Manufacturing

Carbon steel is applied in manufacturing and building various vehicle components. For instance, engine parts, bodies, and axles. Given that vehicles go through significant loads and vibrations, durable materials are essential. So, carbon steel is used to ensure it can withstand these conditions effectively.

Railways

Carbon steel is vital in the railway sector, used for rails, crossties, locomotives, and cars. Trains face challenges similar to those of vehicles, enduring pressure and vibrations. Carbon steel guarantees its durability and reliability in these conditions.

Machinery

Carbon steel plays a crucial role in machinery manufacturing. We employ it to craft gears, shafts, and machine frames. Its solidness and malleability ensure the efficiency of machinery across diverse industries.

Aerospace

Moreover, professionals use Carbon steel in the aerospace industry. It contributes to aircraft construction and manufacturing of rocket components. It also plays a role in producing satellites and exploration robots.

Plus, its remarkable corrosion resistance makes it the go-to choice. It can endure the challenging conditions encountered in aerospace applications.

Corrosion Resistance

Due to its impressive corrosion resistance, carbon steel stands out as every industry’s choice.

It can endure the corrosive impact of chemicals and moisture. Besides, it can resist environmental elements. That guarantees its durability and reliability across various applications.

In construction, infrastructure, and automotive manufacturing, carbon steel proves its durability as it maintains high quality. Carbon steel’s corrosion resistance extends the lifespan of structures and equipment. On top of that, it minimizes maintenance needs.

Available Types

When it comes to steel, each type has its own unique characteristics. This is particularly evident in Carbon steel.

If you’re curious about the uses and features of each type, we’ll guide you through it. Yet, here’s an insight into the composition of each type:

| Type of Carbon Steel | Carbon Composition |

| Low Carbon | Approximately 0.05 to 0.30% |

| Medium Carbon | Approximately 0.30 to 0.60% |

| High Carbon | Approximately 0.61 to 1.00% |

Let’s discover each type of carbon steel:

Low Carbon Steel

We commonly refer to this steel as mild steel. It exhibits lower strength compared to higher carbon variants. With a carbon content capped at 0.30%, it stands as one of the most prevalent grades.

Despite its relatively modest strength, low-carbon steel finds wide application in structural projects. Additionally, it serves in machinery components.

It offers cost-efficient machining solutions due to its ease of shaping. This property accelerates production schedules and lowers machining expenses compared to alternatives like aluminum.

Medium Carbon Steel

Now we move to the second type, which is Medium carbon steel. Medium carbon steels contain a bit more carbon, ranging from approximately 0.31% to 0.60%.

It strikes a balance between low-carbon steel’s ductility and high-carbon steel’s toughness.

When compared to carbon-free steels, medium-carbon steels are stronger. It comes as a result of their higher carbon composition.

High Carbon Steel

The third type is high-carbon steel. It surpasses plain mild carbon steel in both strength and toughness. Carbon content typically ranges from 0.60% to 1.5%. On the other hand, high-carbon steels have exceptional strength, toughness, and corrosion resistance.

That said, these properties are beneficial in many applications, especially where steel faces frequent wear without breakage. High-carbon steel is most effective in producing robust steel products – for example, cutting and chiseling tools, as well as in railway construction.

Machinability

Machinability usually refers to a material’s ease of shaping. Plus, it’s easy to cut during machining processes. It is a crucial element for ensuring efficient production and cost efficiency.

Low carbon grades typically offer superior machinability, facilitating smooth cutting and shaping operations. In contrast, high-carbon steel, valued for its robustness, presents challenges.

Medium carbon steel is a balance between machinability and strength. It provides an excellent level of machining ease while preserving robust mechanical properties. Choosing the correct grade of carbon steel is essential. As a result, it optimizes machining efficiency and guarantees high-quality end products.

Recyclability

Carbon steel, unlike stainless steel, is easy to recycle and reuse many times. As a consequence, Carbon steel minimizes waste and preserves resources.

Besides, this recyclability helps the economy by reducing reliance on raw materials. Plus, the energy-heavy production methods. This material contributes to environmental protection and fosters sustainability.

Standards

Carbon steel standards include specifications and requirements to guarantee quality, performance, and suitability for diverse applications. These standards cover aspects such as chemical composition, mechanical properties, dimensions, tolerances, testing methods, and quality control measures.

The ASTM is highly regarded for its carbon steel standards. It categorizes carbon steel into different grades based on chemical and mechanical properties.

These standards guide manufacturing, testing, and certifying carbon steel products. Also, it ensures the product’s consistency and reliability.

Likewise, International organizations such as ISO and ANSI also set standards for carbon steel. Their goal is to ensure consistency and compatibility across various industries and regions.

These standards are essential for making, selling, and using carbon steel products. They give clear guidelines that manufacturers, suppliers, and users follow. By meeting these rules, carbon steel products can meet quality standards. It also follows regulations and works well in many areas. Let’s state examples like building, manufacturing, and transportation.

Global Production

Global carbon steel production caters to the diverse needs of industries worldwide. For example, China, India, and Japan are the producers. They are equipped with advanced manufacturing capabilities and technologies.

Carbon steel’s versatility and durability make it essential globally in many sectors. Its widespread use highlights its importance in stimulating economic expansion across different areas.

Melodic Influence

Beyond its mechanical uses, it contributes to music with its unique tonal characteristics. It is used in instruments like steel drums, xylophones, guitars, and pianos. That helps the musical instrument produce captivating tones with clarity and depth.

Its density and rigidity enable seamless transmission of sound waves. Thus, it enriches musical compositions across genres. From rhythmic percussion to harmonious strings, carbon steel’s melodic influence is lasting.

Economic Impact

Carbon steel is a cornerstone of the global economy due to its dominant worldwide use across various sectors and industries. Carbon steel has made an economic revolution. We will state some examples of the financial prosperity caused by carbon steel.

Economic Growth

Carbon steel’s versatile use powers growth across automotive, infrastructure, and construction industries.

Additionally, it sparks innovation and fosters competitiveness. It’s an essential element for driving overall economic expansion and prosperity.

Employment Opportunities

A key factor of economic prosperity is creating job opportunities across various sectors. It includes mining, construction, and transportation.

Global Supply Chain Impact

Carbon steel is a vital part of global supply chains due to its versatility, strength, and affordability. It progresses through the supply chain, from raw material extraction to production.

Infrastructure Development

Carbon steel plays a vital role in building trade infrastructure. Such as transportation networks and industrial facilities, which are crucial for commerce.

Its strength makes it perfect for constructing bridges, highways, ports, and railways. Thus, it helps goods move between regions. Its affordability allows for cost-effective infrastructure projects. Hence, it drives economic growth and connects regions globally.

Renewable Energy Infrastructure

Interestingly, carbon steel is a part of the growth of renewable energy infrastructure. It is stimulating the shift to a more sustainable future. Let’s discover how this is being made.

Wind Turbines

It contributes to the expansion of the wind energy sector within renewable energy. Specifically, it serves as a foundational material in the production of turbine blades. It guarantees their resilience in challenging environmental conditions.

Solar Panels

Carbon steel serves as a crucial element in the production of solar panels.

The support structures of solar panels frequently utilize carbon steel to ensure longevity. Additionally, experts use carbon steel in solar racking systems. It facilitates the efficient installation and alignment of solar arrays.

Infrastructure Support

Adding to renewable energy components, carbon steel supports infrastructure in clean energy distribution. Carbon steel pipelines transport gases and liquids to power facilities and networks. It is also used in substation and tower construction. It ensures efficient electricity transmission from renewables to users.

Durability and Sustainability

As mentioned before, carbon steel has eco-friendly benefits attributed to its sustainability. It’s reliable and cost-effective for renewable energy projects. Moreover, its recyclability allows for reduced environmental impact through reuse and recycling efforts.

Oil and Gas

Contrary to common knowledge, carbon steel has a relevant role in the oil and gas industry. Its strength ensures durability in challenging environments. Be it in extraction, processing, or transportation phases.

Moreover, its corrosion resistance ensures the durability of vital infrastructure, such as pipelines, storage tanks, and equipment. Furthermore, its cost-effectiveness makes it the ultimate choice for constructing essential infrastructure.

Partner with Alloyxpert for Carbon Steel

Alloyxpert is unrivaled in high-quality carbon steel solutions. Our services are superior, and here is why:

Solid Experience

Alloyxpert has been making carbon steel for a long time. Thus, we have unmatched expertise in producing and refining this material. Our staff members are highly trained to handle your queries about carbon steel.

Individualized Approach

We are aware that each project has different specifications. That’s why Alloyxpert provides individualized services to address your unique requirements. We can fulfill your specific needs in terms of grade, size, and surface treatment.

Smooth Supply Chain

Count on a dependable and good supply chain when you work with Alloyxpert. To keep your projects on track, reduce downtime, and maximize production, we prioritize prompt delivery.

Superior Customer Care

Here at Alloyxpert, we value our customers’ satisfaction more than anything else. From timely responses to individualized support, our staff is devoted to satisfying you. We collaborate with you to address any queries or issues regarding carbon steel.

You can rely on us to be your go-to supplier for premium carbon steel.

Final Thoughts

So, the benefits of carbon steel are countless and boundless. Its cost-effectiveness and distinction from plain steel are also important. Adding on top of it is its versatility. Carbon steel offers advantages unmatched by other types of steel.

Moreover, carbon steel is not only known for its strength but also for being recyclable. Besides, Carbon Steel fosters the growth and development of the economy. It contributes to providing job opportunities and fosters innovation.

All in all, now we know why companies invest in Carbon Steel and why they keep coming back for more. Get in touch with Alloyxpert right away for any questions or to place an order for carbon steel.