In the vast domain of materials, steel has a unique balance. It has unmatched strength and versatility. These benefits have earned it the title of ultimate material. Nevertheless, there is an enthralling variety of variants within the realm of steel.

Not every steel possesses the same quality or characteristics. Steel comes in many varieties, like the tools in a toolbox. Each is good at different tasks. This guide will decrypt the encryption on three common types of steel.

The three types are alloy steel, carbon steel, and stainless steel. You will go from a novice to a steel expert by understanding these differences. You will be ready to pick the best material for your next project. This knowledge will let you make smart choices and ensure your project’s success!

Stainless Steel Overview

It is the most rust-resistant material. When exposed to air or a passive environment, the 10.5% chromium reacts with oxygen. It creates a thin, invisible layer of chromium oxide on the steel’s surface. This layer of chromium oxide is a tough barrier. It prevents further oxidation and corrosion of the steel below.

Nickel increases toughness and ductility. This makes the steel easier to shape and use. That makes it great for many uses. These include architectural panels and food equipment.

Molybdenum is useful in petrochemical and chemical applications. It resists some acids well.

Advantages of Stainless Steel

- The excellent chromium oxide layer makes it resistant to corrosion. It works in many places, making it a top choice in humid, chemical, or harsh weather.

- Stainless steel has an attractive finish. Architects, food processors, and high-end cutlery makers all favor this material. They like it for its smooth, polished surface.

- Stainless steel naturally resists corrosion. So, it needs less maintenance than other types of steel. It is a significant benefit when regular cleaning or painting is impractical.

- Specific stainless steel grades are exceptional because of their high flexibility and strength. They excel at demanding structural jobs, such as building and bridging.

Disadvantages of Stainless Steel

- Stainless steel is costly. Adding nickel and chromium makes this especially true.

- Machining stainless steel is challenging. This could result in increased costs and the need for specialized equipment.

Carbon Steel Overview

Carbon steel is an iron metal with different amounts of carbon. The amount of carbon in steel has a significant effect on its qualities. Because it has less carbon, it is more flexible and easy to shape and work with. Higher carbon makes it stronger, more complex, and less malleable.

Advantages of Carbon Steel

- Carbon steel is cheap. It needs fewer alloying elements. That makes it the top choice for budget applications.

- Steel’s many carbon content levels make it versatile. They enable customization to meet varied needs for strength. So, steel can serve many purposes.

- Welding and machining carbon steel are simpler than with other types of steel. It leads to lower costs and simpler processes.

Disadvantages of Carbon Steel

- Carbon steel lacks the chromium oxide coating found in stainless steel. Thus, its rust and corrosion are more prone to occur in moist or corrosive surroundings. Paints or protective coatings are, therefore, essential for outdoor applications.

- Carbon steel is less robust than alloy steel, particularly under high temperatures. Thus, it could be more suitable for demanding applications.

Alloy Steel Overview

It bridges the gap in properties and complexity. It sits between carbon and stainless steel. Besides, it has iron and carbon. Other elements include manganese, nickel, chromium, molybdenum, and vanadium. They are in precise amounts.

The mixture gives the metal the right qualities for specific applications. The type and quantity of added alloys significantly impact the steel. They determine the final strength and toughness. They also affect hardenability and corrosion resistance.

Advantages of Alloy Steel

- Adding alloying elements improves carbon steel. It greatly boosts its strength, toughness, and wear resistance. It also increases its ability to harden. That makes it suitable for high-pressure machinery, gears, and shafts. It’s also good for other challenging tasks that need excellent performance.

- You can tailor alloy steel to meet the requirements of an application. We achieve this by altering the alloying components. That makes it possible to choose materials optimally.

- Alloy steels may have specific alloying elements. However, they may not resist corrosion, and neither may stainless steel. They can tolerate some corrosive situations better. These alloy steels can serve as a decent alternative to stainless steel. This is true in cases where cost or other factors are essential.

Disadvantages of Alloy Steel

- Adding alloying elements raises steel’s price. It is higher than carbon steel but often cheaper than stainless steel. The exact cost will change depending on the type and amount of alloying materials used.

- Choosing the best alloy steel is hard. You must weigh the necessary properties against the steel’s environment. Consult with a qualified steel supplier or engineer.

Stainless Steel vs. Carbon Steel vs. Alloy Steel

These three types have different properties that make them suitable for other uses.

1) Composition and Alloying Elements

Stainless steel contains chromium(10.5%), nickel, molybdenum, and nitrogen. These elements improve its properties.

Carbon steel is mostly iron with varying carbon content (0.02% to 2.0%).

Alloy steel has iron and carbon. But it also has other parts, like manganese, nickel, chromium, molybdenum, and vanadium. The specific extra elements depend on the desired properties.

2) Mechanical Properties

Grades of stainless steel have different strengths. Though perhaps not as robust as other alloy steels.

As the carbon steel content rises, it loses flexibility and strength. It usually has less strength than alloy steel.

Alloy steel can be robust, tough, and more wear-resistant. It is also easier to strengthen than regular steel. The qualities of alloy steel depend on the alloying elements used.

3) Availability

Stainless steel is available in many grades and finishes.

Carbon steel is a prevalent steel type and easy to find.

Alloy steel may need longer lead times. Depending on the desired alloy, specific orders might be required.

4) Suitable applications and industries

Stainless Steel

- Food processing equipment

- Medical devices

- Architectural panels and railings

- Chemical and petrochemical plants

- Automotive trim

- High-end cutlery

Carbon Steel

- Structural components (beams, columns)

- Pipes and tubes

- Automotive components (frames, bodies)

- Nails, screws, and other fasteners

- Tools and machinery (excluding high-performance applications)

- Construction Equipment

Alloy Steel

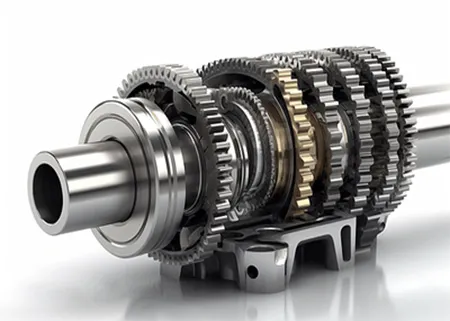

- Gears and shafts

- Bearings

- Crankshafts and other high-stress automotive components

- Pressure tanks and boilers

- Cutting tools and dies

- Bridges and other high-strength structures

5) Corrosion Resistance

Stainless steel has excellent corrosion resistance.

Carbon steel is susceptible to rust.

In alloy steel, it depends on the materials used. It might be better than carbon steel.

Quick Recap of the Key Differences

| Feature | Stainless Steel | Carbon Steel | Alloy Steel |

| Main Alloying Element | Chromium (min. 10.5%) | Carbon (up to 2.1%) | Varies (mostly Manganese, Nickel, Chromium) |

| Cost | High | Low | Moderate |

| Strength | Varies | Varies | High |

| Corrosion Resistance | Excellent | Low | Varies |

| Ductility | Varies | High | Varies |

How to Select Between Carbon, Alloy, and Stainless Steel?

To get the best project results, pick the right steel type. It depends on many important factors. You need to consider them carefully. These include:

1) Strength

Consider the required load capacity and the stress that the steel will face. Carbon steel may be enough for less demanding scenarios with lower stress. However, alloy steel is generally stronger for demanding applications.

2) Corrosion Resistance

Consider the environment the steel will face, including moisture and chemicals. In harsh environments, stainless steel resists corrosion well. Some alloy steels are even better at this than carbon steel. For outdoor use, carbon steel may require coatings.

3) Cost-Effectiveness

Depending on the project budget, choosing the suitable material is essential. Stainless steel costs more because it has chromium and other alloys added to it. Carbon steel is the least expensive choice. Alloy steel is in between. Costs vary depending on the alloying elements used.

4) Specific Requirements

You should also consider the weight and how easy it is to machine, weld, and form the material. These factors change depending on the use. Stainless steel may be harder to work with than carbon steel. We can make certain steels fit specific needs depending on how well they weld.

What Are the Common Applications of Stainless Steel, Carbon Steel, and Alloy Steel?

Knowing each type of steel is essential. However, real-life situations demonstrate actual knowledge. To help us understand material selection, let’s look at typical uses for each type of steel. We’ll also go into a few case studies.

1) Stainless Steel Applications

Food processing equipment

Stainless steel is the best material for making tools for handling food. The material is very resistant to rust and is very clean. These keep food acids from tainting it and making it taste acidic. Like, 304 stainless steel can be used in many different ways.

Many food plants use it to make tanks, lines, conveyor belts, and mixing bowls. 316 stainless steel is very good at keeping pits from forming. It keeps the food safe and the quality of the result high. It works great in places where salt needs to be exposed a lot, like pickling lines.

Medical Devices

It comes in many types of stainless steel. An example is 316L stainless steel. It has a low carbon percentage and is biocompatible. It is also used to make bone screws, surgery tools, and joint replacements. A longer life is also guaranteed, lowering the risk of allergic responses. Because it doesn’t rust, it can be used for many medical equipment.

Architectural panels and railings

Many architects use stainless steel. It is vital, needs little maintenance, and looks good. Grades such as 304L come in many shapes, making them ideal for architectural panels. In addition, railings and other components last a long time. Stainless steel is easy to maintain and work with. It lasts a long time and needs little light. It doesn’t rust.

2) Carbon Steel Applications

Structural Components

Steel made of carbon is cheap and strong for its weight. Therefore, beams, columns, and trusses commonly use carbon steel. A36 steel is a typical example. It is used in a variety of structures. This is due to its balanced strength and weldability. ASTM A992 steel is better for projects that need more strength. It includes high-rise skyscrapers.

Tubes and Pipes

Carbon steel pipes and tubes are cheap and practical. Therefore, the industrial, plumbing, and building industries often use them. The required pressure determines the use of different carbon steel grades. For instance, oil and gas use high-pressure applications. They can use robust grades, such as API 5L X. In contrast, low-pressure applications use ASTM A53 steel. These include things like water pipelines.

Automotive Components

People often use cold-rolled steel sheets for car body panels. They do so because the sheets are easy to shape. Car parts such as frames, axles, and engine blocks utilize specific grades of carbon steel. These parts require both strength and affordability. In the automotive sector, carbon steel is a vital component.

3) Alloy Steel Applications

Gears and shafts

It is easy to work with, strong, and tough. It works great in places with a lot of stress, like gears and shafts. AISI 4140 steel is an example. It’s a combination of chromium and molybdenum. It’s a good metal for making gears and wheels for power systems.

Bearings

Bearings should be able to handle heavy loads and wear down slowly. SAE 52100 mixed steels contain a lot of chromium. These steels last long and can handle wear, making them perfect for bearings. Numerous items, including cars and large machinery, utilize bearings.

Pressure Vessels and Boilers

People often use ASTM A516 Grade Essure containers 70 steel for pressure. This material is solid and simple to weld. There are also metal steels that boilers choose. High pressures and temperatures make the boilers work. These steels were selected because they don’t creep easily. It’s wise to use alloy steel. When the temperature is high, they work well. They are needed for pressure tanks and boilers because of this.

Crankshafts and Other High-Stress Automotive Components

4340 chromoly is a solid alloy steel. Crankshafts undergo immense forces during engine running. They also resist fatigue and are easy to machine. People often choose them for crankshafts and other high-stress car parts. These parts need to be reliable and high-performing.

What Are the Popular Case Studies of Stainless Steel, Carbon Steel, and Alloy Steel?

Case Study 1 – Constructing a Sustainable Bridge

Case Study 1 is about building a sustainable bridge. It’s about balancing strength, cost, and corrosion resistance.

What Are the Objectives?

A city is planning to construct a new bridge over a saltwater river. The bridge needs to be:

- Strong: capable of withstanding heavy traffic loads and harsh weather conditions.

- Durable: It lasts for decades with minimal maintenance requirements.

- Cost-effective: Fits within the project’s allocated budget.

- Corrosion Resistant: It withstands the corrosive effects of saltwater exposure.

What Are Initial Considerations?

Alloy steel offers a compromise. It falls between carbon steel and stainless steel. Both of those are cheap and rust-prone in saltwater. Stainless steel can be more costly than carbon steel.

What Is the Solution?

The project engineers decided to use a blend of steel types:

- HSLA steel is stronger and lighter than carbon steel. It also resists corrosion better. It provides a saltwater-environment-friendly balance between cost and long-term durability.

- The bridge has a deck and railings. Weathering steel, an alloy with a unique composition, forms the deck and railings. Over time, this steel develops a coat of protective rust. This rust reduces the need for maintenance and improves its appearance.

- Fasteners and connecting parts need corrosion resistance. Stainless steel has this, so it’s a great choice. It ensures long-lasting structural integrity.

What Are the Results?

The project achieved the required combination of strength, durability, and low cost. It also met the need for corrosion resistance. It did this by carefully picking different types of steel for their attributes. This method guarantees a long-lasting bridge. It would need little maintenance.

Case Study 2 – Upgrading a Food Processing Plant

The plant needs to upgrade its conveyor belts. The plant uses the belts to move fruits and vegetables.

What Are the Objectives?

Critical considerations for a food processing plant include:

- Hygiene: The material must not react with or contaminate food products.

- Moisture, cleaning chemicals, and acidic foods. They must resist corrosion.

- Cleanability is key. The surface must be smooth. It must be easy to clean to stay sanitary.

- The belts must withstand constant wear and tear during daily operations.

What Are Initial Considerations?

Even though carbon steel is cheaper, it can rust and contaminate food. Although it costs more, stainless steel lasts longer and is easy to clean.

What Is the Solution?

The food processing facility chose upgraded conveyor belts. 304 stainless steel composes them. This particular stainless steel grade offers the following:

- It resists corrosion and rust caused by acidic foods, cleaning products, and dampness. It reduces contamination hazards.

- The smooth surface makes cleaning easy. It is essential for maintaining hygiene in food facilities.

- Durability is key. We use 304 stainless steel for the belts’ construction. It is tough and wear-resistant. Therefore, they can withstand regular use and cleaning.

What Are the Results?

The studies show that understanding steel properties is essential. They also show the need to choose the best type based on a project’s requirements. Engineers can make informed decisions. They consider factors like strength, corrosion resistance, hygiene, and cost. These decisions ensure successful projects.

The plant prioritized hygiene and safety. It opted for 304 stainless steel. It reduced the risk of food contamination and made cleaning easier. Moreover, it led to better food safety and production efficiency.

FAQs

1) Which Type of Steel Is Best for Outdoor Applications?

Galvanized carbon steel has a zinc coating. It could be less expensive for less complicated outdoor pursuits. But stainless steel is usually best for outdoor use. It resists corrosion better.

2) Is It Possible to Use Carbon Steel in Corrosive Environments?

Stainless steel, or some alloy steels, works better in wet, salty, or harsh chemical places. In the long run, they work better. However, some areas can use carbon steel with the proper coatings. They are controlled and corrosive. The coatings provide a barrier against corrosion.

3) What Are the Typical Alloying Elements Found in Alloy Steel?

Manganese, nickel, chrome, molybdenum, and vanadium are common alloying elements in steel. The type of element and its amount significantly impact the steel’s final properties.

4) Is Alloy Steel More Expensive Than Stainless Steel?

No, generally speaking! Alloy steel has more components, so it costs more than carbon steel. However, alloys and stainless steel costs can vary depending on the alloy grade and mix.

5) How Do I Choose the Right Type of Steel for My Application?

It is best to ask a steel supplier like Alloyxpert. They know about the different types of steel and their properties. Moreover, they can help you pick the best steel. They do this by taking into account the application’s unique needs. These needs include strength, corrosion resistance, cost, and the environment.

6) What Factors Influence the Cost of Steel?

Several factors affect the price of steel, including:

- Additional metals and chromium fortify stainless steel. It is more expensive than carbon steel. The specific alloys used determine how much alloy steel costs.

- The pricing of steel products (sheets, bars, pipes, etc.) might vary depending on their size and shape.

- Buying more steel lowers the cost per unit. It happens because of bulk discounts.

- Steel can have a specific surface finish, like polished stainless steel. It may cost more than a standard mill finish.

7) Can Carbon Steel Be Galvanized?

Yes, galvanization is a standard procedure. We use it for pipes, fasteners, and roofing sheets. A zinc layer is applied to carbon steel to increase corrosion resistance.

8) How Does the Recycling Process Differ for Stainless Steel, Carbon Steel, and Alloy Steel?

The basic process for recycling steel is the same for all three types. Steel is magnetic. An electromagnet can easily separate it from other materials. Recycled steel scrap undergoes melting and refinement to produce new steel goods. But there are some differences:

- Alloy steel contains alloying elements. Recycling may require extra steps to maintain the final product’s proper chemistry.

- During recycling, we must sort stainless steel by grade. We must also keep the properties we want in the recycled steel.

9) What Are Some Emerging Trends in the Steel Industry Relating to These Types of Steel?

The steel business emphasizes cost-effectiveness, performance, and sustainability. It is constantly changing. The following significant trends are listed:

- Because they are solid and formable, AHSS steels are considered advanced. They let the automotive industry make lighter car bodies for better fuel efficiency.

- There is ongoing research on how to create new steel alloys. These alloys will push the limits of strength, corrosion resistance, and high-temperature performance. They will have qualities tailored for specific uses.

- Steel production might harm the environment, and reducing this is a growing concern. Technology is helping the steel industry. It does this by improving the use of recycled steel.

Final Thoughts!

It’s critical to distinguish between alloy, carbon, and stainless steel. It is helpful when choosing materials for numerous engineering projects. Carefully consider the project’s requirements. These include strength, corrosion resistance, cost, and specific functions. You can then pick the type of steel that offers the best performance.

As always, talking to steel suppliers would be helpful. Our engineers at Alloyxpert can offer invaluable advice. They specialize in material selection. Besides, they can help you choose the best steel type. They can also guarantee your project’s success.