Table of Contents

Introduction

Heat treatment plays a crucial role in improving the strength and durability of steel. But when working with it, many people get confused by key differences that can affect the final product. Let’s break down these “5 Key Differences” to help you avoid common mistakes and get the best results.

Quenching Heating Temperature vs. Quenching Temperature

When you’re working with steel, there’s a difference between the quenching heating temperature and the quenching temperature, though people often mix them up.

- Quenching Heating Temperature: This is the temperature you heat the steel to before you quench it. You hold it at this temperature long enough for the steel to become uniformly austenitized.

- Quenching Temperature: This is the actual temperature the steel is at when you remove it from the furnace and immerse it in the quenching medium (like oil or water).

Why does this matter? The steel cools down between being taken out of the furnace and entering the quenching medium. So, the quenching heating temperature is usually higher than the quenching temperature. Keeping this straight can help ensure the right hardening effect.

Tip: When specifying temperatures, the industry often uses austenitization temperature (Ta) for heating and quenching temperature (Tq) for the quenching stage. There’s generally a 100°C difference between them.

Heating Time vs. Holding Time

Heating and holding time are different, but many don’t realise the impact they have on steel’s properties.

- Heating Time: This is how long it takes to heat the steel from room temperature to the desired temperature.

- Holding Time: This is the amount of time you keep the steel at that desired temperature.

Why is this important? Steel materials heat up differently, so one size doesn’t fit all. For example, alloy steels might need less holding time than tool steels, which require a longer time for carbon to fully dissolve. Also, larger pieces take longer to heat, so you’ll need to adjust both heating and holding times accordingly.

Cooling Methods vs. Cooling Effects

Different cooling methods can change how steel performs after heat treatment. The three most common methods are:

- Air Cooling: Slow cooling, best for steels with lower hardness requirements.

- Oil Cooling: Moderate cooling, suitable for most steels.

- Water Cooling: Fastest cooling, needed for higher hardness.

But here’s the catch: The size and shape of the steel also play a role. Smaller pieces may cool quickly enough with oil, while larger ones may not cool as fast and might need water to get the desired hardness.

Tip: Always test your cooling method for the specific material and size you’re working with to get the right result.

Cooling Capacity vs. Hardenability of Quenching Liquids

Quenching liquids are essential during heat treatment, but it’s important to understand two key properties:

- Cooling Capacity: This tells you how quickly the quenching liquid can cool down the steel.

- Hardenability: This shows how effective the quenching liquid is at hardening the steel.

Both properties aren’t always the same. You may find two quenching liquids with similar cooling capacities, but one may perform better at hardening due to its specific characteristics. The size, shape, and surface condition of the steel, as well as the liquid’s temperature, can all affect its performance.

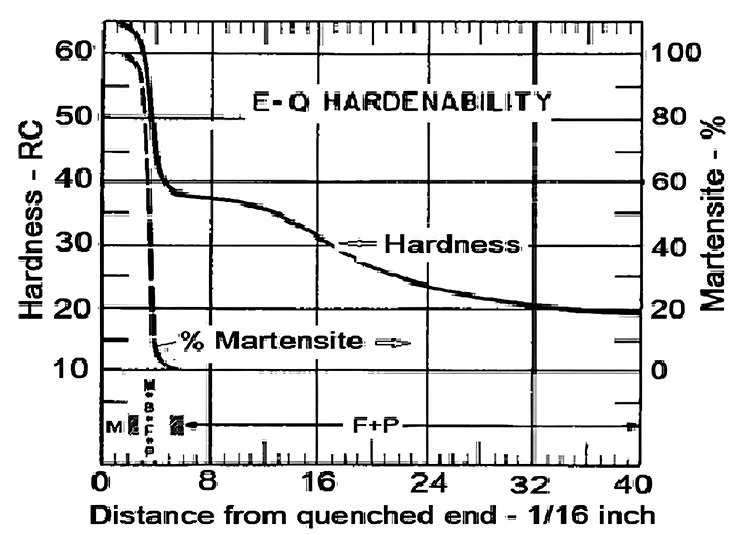

Surface Hardness vs. Hardened Depth

Both surface hardness and hardened depth are indicators of how well the quenching process has worked:

- Surface Hardness: The hardness you get on the surface of the steel after quenching.

- Hardened Depth: How deep inside the steel the hardness extends.

The goal is to get a high surface hardness while ensuring the right depth. Some materials, like high-carbon steels, achieve deeper hardened depths with higher quenching temperatures. Other materials, like low-carbon steels, need faster cooling to improve surface hardness.

Tip: If you’re after specific hardness results, tweak the temperature and cooling method to get the right combination of surface hardness and depth.

Conclusion

Understanding these “5 Key Differences” in heat treatment is essential for achieving the best steel performance. By adjusting the heating and cooling parameters, quenching liquids, and timing, you can fine-tune the process for the desired results. Keep these differences in mind, and you’ll be well on your way to better, more reliable heat-treated steel.

FAQs

Which cooling method is best for my steel?

It depends on your steel and the final properties you need. For high hardness, you might need water cooling, but for more general purposes, oil or air cooling could work.

Why do quenching liquids matter?

Quenching liquids cool the steel and help it harden. Some liquids cool faster, while others are better at achieving the right hardness. Choose the one that fits the steel’s needs.

How can I achieve the right hardness in my steel?

The key is balancing quenching temperature, cooling speed, and holding time to get the right surface hardness and depth. Each steel grade may need different adjustments.

Read More:

Why Heat Treatment of Steel is Important?