Table of Contents

Introduction

Choosing between monel vs stainless steel depends on the specific requirements of your project. Monel, a nickel-copper alloy, is known for its superior corrosion resistance, especially in marine environments. Stainless steel, an iron-chromium alloy, offers versatility, affordability, and corrosion resistance across many industries. This article will compare their key differences, helping you make an informed decision.

What is Monel?

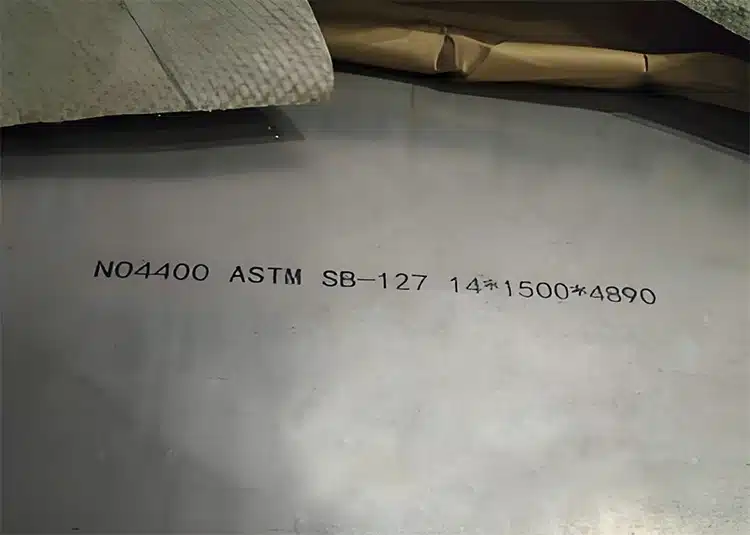

Monel is a high-performance nickel-copper alloy known for its excellent resistance to corrosion and extreme temperatures. Its composition includes a significant amount of nickel (typically around 65-70%) combined with copper and trace amounts of manganese, iron, and other elements. This unique composition makes monel ideal for use in harsh environments, particularly in marine and chemical industries.

What is Stainless Steel?

Stainless Steel is an iron-chromium alloy, known for its excellent corrosion resistance, durability, and versatility. The high chromium content (usually above 10.5%) forms a thin oxide layer on the surface, protecting the metal from rusting when exposed to moisture or chemicals. Additionally, nickel and other elements such as molybdenum are often added to enhance specific properties like strength and resistance to extreme conditions.

What Are the Differences between Monel Metal and Stainless Steel?

When comparing Monel and Stainless Steel, several key factors come into play, including chemical composition, corrosion resistance, strength, cost, and specific applications. Each material excels in different areas, making them suitable for distinct environments and uses.

Monel vs Stainless Steel Chemical Composition

| Element | Monel | Stainless Steel |

| Nickel (Ni) | 63-70% | 8-35% (depending on the grade) |

| Copper (Cu) | 20-29% | Trace |

| Iron (Fe) | 2-5% | Balance (~65-75%) |

| Chromium (Cr) | Trace | 10.5-30% |

| Manganese (Mn) | Up to 2% | 2% |

| Carbon (C) | 0.3% (max) | 0.03-1% (depending on grade) |

| Silicon (Si) | Trace | Up to 1% |

| Sulfur (S) | Trace | 0.03% (max) |

| Molybdenum (Mo) | Trace | Optional (up to 3%) |

| Phosphorus (P) | Trace | 0.045% (max) |

| Nitrogen (N) | – | Trace |

Monel is a nickel-copper alloy with high nickel content (63-70%) and trace amounts of iron, which grants it exceptional corrosion resistance in harsh environments. Stainless steel is an iron-chromium alloy that offers corrosion resistance and versatility across various grades, depending on its nickel, chromium, and other alloying elements like molybdenum and carbon.

Monel vs Stainless Steel Corrosion Resistance

| Environment | Monel | Stainless Steel |

| Marine (Saltwater) | Excellent corrosion resistance | Good resistance but less effective than Monel in seawater |

| Acidic Environments | Superior resistance to acids like sulfuric and hydrofluoric acids | Moderate resistance to mild acids, not suitable for strong acidic environments |

| Chloride-Containing Atmospheres | Highly resistant | Prone to pitting and crevice corrosion in chloride-rich conditions |

| General Industrial Use | Excellent in highly corrosive environments | Sufficient for general industrial applications, may suffer pitting in extreme conditions |

Monel exhibits superior corrosion resistance in marine and acidic environments, excelling in seawater and exposure to strong chemicals. While stainless steel offers good corrosion resistance, it is more prone to pitting in chloride-rich or highly acidic environments.

Monel vs Stainless Steel Strength and Durability

| Property | Monel | Stainless Steel |

| Tensile Strength | 550-620 MPa | 485-900 MPa (depending on grade) |

| Yield Strength | 240-345 MPa | 170-600 MPa (depending on grade) |

| Hardness (Brinell) | 135-200 HB | 123-290 HB (depending on grade) |

| Elongation at Break | 30-40% | 40-50% |

| Temperature Tolerance | Retains strength up to 540°C (1000°F) | Up to 800°C (depending on grade) |

| Durability | Extremely durable in harsh environments | Durable for a wide range of applications |

| Resistance to Wear | High resistance to wear and mechanical stress | Moderate to high (depending on grade) |

Monel offers greater strength and durability, maintaining its properties in high-temperature and high-stress environments like marine and aerospace. Stainless steel is versatile, with a wide range of strengths and wear resistance depending on the grade, but it generally does not match monel in extreme environments.

Monel vs Stainless Steel Price

| Factor | Monel | Stainless Steel |

| Raw Material Cost | Higher due to high nickel content (63-70%) | Lower due to abundant iron and moderate chromium content |

| Manufacturing and Processing | More expensive due to complex processing and limited availability | Less expensive due to mass production and widespread availability |

| Market Price | Generally higher | More affordable |

Monel is generally more expensive than stainless steel because of its high nickel content and more complex manufacturing processes. Stainless steel, being more cost-effective, benefits from easier availability of iron and chromium, and large-scale production, making it a more economical choice in most cases.

Monel vs Stainless Steel Uses

Monel Applications:

- Marine: Propellers, pumps, and other equipment exposed to seawater.

- Chemical Industry: Acid tanks and piping for corrosive chemicals.

- Aerospace: High-temperature components like turbine blades.

- Oil and Gas: Offshore drilling equipment and pipelines.

- Electronics: Corrosion-resistant springs and connectors.

Stainless Steel Applications:

- Food Processing: Equipment and containers for hygiene and corrosion resistance.

- Medical: Surgical tools and implants.

- Construction: Structural and decorative elements in buildings.

- Automotive/Aerospace: Exhaust systems and heat-resistant parts.

- Household: Cutlery, appliances, and furnishings.

Conclusion

Choosing between monel vs stainless steel depends on your specific needs. For marine or chemical environments, go with monel. For cost-effective durability across general applications, stainless steel is the better choice. For expert guidance, contact AlloyXpert for tailored material recommendations or a quote to suit your project.

FAQs

How to tell Monel from stainless steel?

You can distinguish Monel from stainless steel by:

- Appearance: Monel typically has a dull gray finish, while stainless steel has a more polished, shiny look.

- Magnetism: Monel is non-magnetic, while some grades of stainless steel are magnetic.

- Corrosion: Monel resistsseawater corrosion better than stainless steel, which may show rust over time.

Is Monel more expensive than stainless steel?

Yes, Monel is more expensive due to its high nickel content and more complex manufacturing process. Stainless steel is generally more cost-effective and widely used in common applications.

Is Monel 400 better than stainless steel?

Monel 400 is better in marine and chemical environments due to its superior corrosion resistance. However, stainless steel is more versatile and cost-effective for general industrial and consumer use.

Read More:

Inconel vs Monel: A Comprehensive Comparison Guide

Understanding the Differences Between Stainless Steel, Carbon Steel, and Alloy Steel