Table of Contents

Introduction

The Martensite Strengthening Mechanism is what makes martensite the go-to microstructure for high-strength steel. It’s a mix of processes that increase steel’s strength, toughness, and hardness, making it ideal for demanding applications. These include solid solution strengthening, phase transformation hardening, aging strengthening, substructural strengthening, and fine grain strengthening. Each of these plays a unique role, and understanding them can help you make better choices when working with steel.

How Solid Solution Strengthening Improves Martensite?

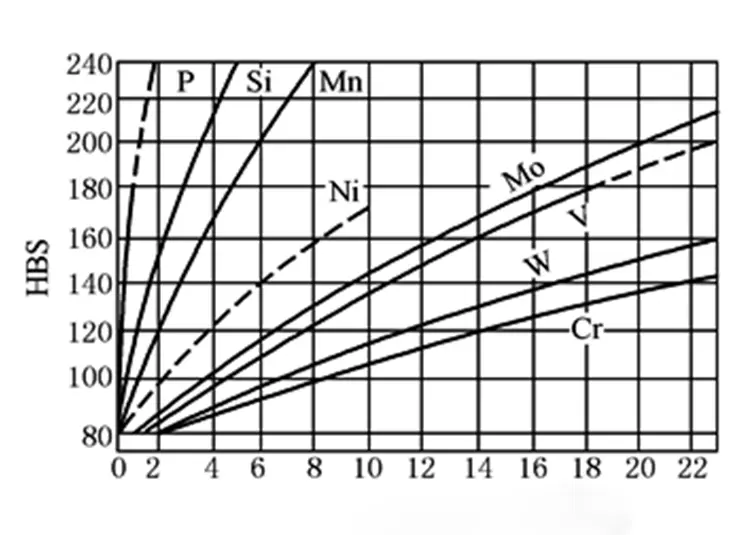

Solid solution strengthening happens when carbon and other alloying elements dissolve into the steel lattice during rapid cooling. This creates a supersaturated solid solution, causing lattice distortion. Think of it like stretching a rubber band too far—it creates stress that blocks dislocations from moving. Carbon is the star player here, as it introduces more distortion than most other elements. Alloying elements like chromium and tungsten contribute too, but their effects are smaller.

For optimal solid solution strengthening, controlling carbon content is crucial. More carbon increases strength, but too much can make the steel brittle. Precise quenching ensures that carbon stays in solution without forming carbides prematurely.

Mass fraction (%) of alloying elements dissolved in the iron matrix

Phase Transformation Hardening: The Core of Martensite’s Strength

When austenite transforms into martensite during rapid cooling, it’s not a smooth process. Instead, it creates a dense network of defects, including dislocations, twins, and stacking faults. These defects make it harder for dislocations to move, which directly increases the material’s strength.

Even carbon-free martensite can reach a yield strength of around 280 MPa, and adding carbon enhances this significantly. However, consistency in cooling is critical. Uneven cooling can lead to undesirable variations in microstructure, weakening the steel.

Why Aging Strengthening Is a Game-Changer?

After martensite forms, carbon atoms continue to move, albeit slowly. They cluster near defects like dislocations and form carbide precipitates. These precipitates pin down the dislocations, preventing them from moving and further increasing strength and hardness. Aging strengthening happens quickly—even at room temperature—and can dramatically improve the steel’s hardness without sacrificing too much ductility.

Controlled tempering is key to harnessing this mechanism effectively. By carefully adjusting temperature and time, you can fine-tune the balance between hardness and toughness, depending on your application.

The Role of Substructures in Martensite Strengthening Mechanism

Martensite’s performance is heavily influenced by its substructure. It primarily forms as lath martensite or plate martensite. Lath martensite contains a high density of dislocations, which allows it to deform slightly under stress, making it more ductile and tough. Plate martensite, on the other hand, is dominated by twins, which enhance hardness but reduce plasticity.

Choosing the right substructure depends on your application. For structural components that need to withstand impact or stress, lath martensite is the better choice. If extreme hardness is the goal, such as for cutting tools, plate martensite may be more appropriate.

Fine Grain Strengthening: Strengthening at the Microscopic Level

Smaller grains introduce more grain boundaries, which act as barriers to dislocation motion. This is the principle behind fine grain strengthening as a strengthening mechanism. Finer grains lead to higher strength, but there’s a limit to how much improvement you can achieve. In medium-carbon steels, fine grain strengthening contributes up to 250 MPa of additional strength before plateauing.

Fine grain strengthening works best when combined with other aspects of the Martensite Strengthening Mechanism, such as phase transformation and solid solution strengthening. It’s not a standalone solution but a complementary one that adds value when applied strategically.

For a deeper understanding of fine grain strengthening and its role in engineering, check out this comprehensive guide on fine grain strengthening principles.

Optimizing the Martensite Strengthening Mechanism

To get the most out of martensite, start with the right carbon content. Too little, and the steel will lack strength; too much, and it becomes brittle. Next, control the cooling process carefully to ensure consistent transformation. Uniform quenching helps avoid unwanted residual stresses. Tempering plays a crucial role too. It allows you to fine-tune the balance between hardness and toughness through controlled aging. Lastly, consider adding alloying elements like nickel or molybdenum to enhance specific properties such as corrosion resistance or toughness.

Conclusion

The Martensite Strengthening Mechanism isn’t just a theory—it’s the foundation for making steel that performs reliably under stress. Whether you’re designing wear-resistant tools, constructing buildings, or manufacturing machinery, understanding these mechanisms helps you make smarter choices. When applied correctly, martensite offers the perfect combination of strength, hardness, and durability, making it an indispensable material in modern engineering.

FAQs

What is the mechanism of martensite transformation?

Martensite transformation is a diffusionless phase transformation where austenite rapidly cools, causing a shear deformation in the lattice. This creates a supersaturated, distorted structure with defects like dislocations and twins, leading to high strength and hardness.

What is the major factor that influences the strength and hardness of martensite?

The carbon content is the main factor. It increases lattice distortion, which blocks dislocation movement, enhancing strength and hardness. Cooling rate and alloying elements also contribute.

What causes the martensite to be so brittle?

Martensite’s brittleness is due to high carbon content, which causes significant lattice distortion and internal stress. Limited dislocation movement and improper tempering can further reduce ductility.

Read More:

Analysis and Handling of Transverse Ridges on Steel Coils

Decoding and Naming Conventions of Steel Grades like Q345B and 304

Oxide Coating on Steel: Protection, Removal & Key Applications