Table of Contents

Introduction

Overheating is a major problem in heat treatment. It weakens the material, damages the structure, and often makes the metal unusable. When the heating temperature goes beyond the material’s limits, grain boundaries start to melt, leading to serious defects. Overheated materials lose strength, become brittle, and in many cases, must be scrapped.

What Is Overheating in Heat Treatment?

Overheating happens when the heating temperature exceeds the material’s tolerance, causing low-melting phases to melt and remelt at the grain boundaries. This leads to structural weakness, poor mechanical properties, and darkened surfaces due to oxidation.

Signs of Overheated Metal:

- Grain boundary melting – weakening of the material structure.

- Spherical remelting spots – visible under a microscope.

- Blackened or darkened surfaces – due to oxidation at high heat.

Example: Heat Damage in W18Cr4V Steel

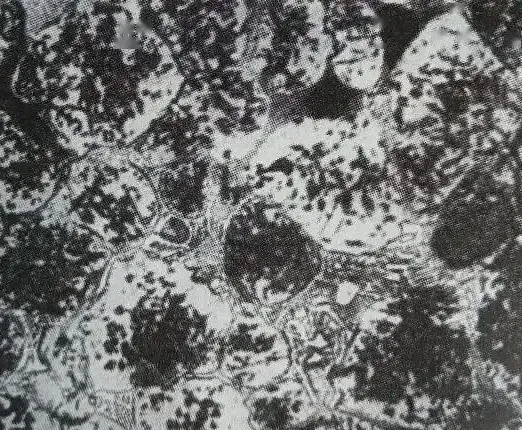

The picture shows:

- White zones: Fine needle-like quenched martensite + retained austenite.

- Black zones: Sorbite + troostite mixed structures.

- Grey fishbone areas: Eutectic ledeburite formed from excessive heating.

Excessive heat causes carbide dissolution and melting at grain boundaries. On cooling, lediburite forms in large quantities, affecting hardness and durability. In tools, this results in deformation, shrinkage, and surface wrinkling, making the tool unusable.

What Causes Overheating?

Excessive Heating Temperature

The most direct cause is an excessively high heating temperature. When the temperature exceeds the material’s safe limit, the low-melting-point phases liquefy, weakening the grain structure.

Extended Heating Time

Even at correct temperatures, prolonged heating time causes grain growth and weakens grain boundaries, increasing overheating risk.

Oxidizing Furnace Atmosphere

A furnace with too much oxygen accelerates oxidation, consuming key elements in the metal. Oxidation at grain boundaries can create low-melting-point oxides, leading to further deterioration.

What Are the Consequences of Overheating?

Loss of Strength

It disrupts the material’s microstructure, leading to a significant decline in mechanical properties. Key performance indicators such as tensile strength, yield strength, and impact toughness are substantially reduced.

Poor Surface Quality

Overheated materials often exhibit darkened or blackened surfaces, along with cracks and peeling defects, which compromise both the material’s aesthetics and functional integrity.

Scrap Material Risk

Once it occurs, the damage is usually irreversible through conventional heat treatment. As a result, overheated materials are often scrapped, leading to significant financial losses.

Fracture Inheritance

Even if a material undergoes reheating and quenching to refine the grain structure, its fracture characteristics may still reflect the original coarse austenite grain structure. This phenomenon, known as fracture inheritance, indicates that excessive heating has a long-term and permanent impact on material performance.

How to Prevent Overheating?

Control Heating Temperature

Temperature control is the key factor in preventing excessive heating. Heating parameters should be accurately set based on the material type, shape, and heat treatment requirements, with real-time monitoring and adjustments during the process.

Manage Heating Time

Overly long heating durations should be avoided to prevent grain growth and grain boundary weakening. The thickness of the material, heating method, and process requirements should determine the appropriate heating duration.

Optimize Furnace Atmosphere

The furnace atmosphere significantly influences oxidation and excessive heating tendencies. To minimize oxidation and overheating risks, it is advisable to use reducing atmospheres or inert gas atmospheres.

Conduct Regular Quality Checks

Throughout the heat treatment process, stringent quality inspections should be conducted. Microstructural analysis and mechanical testing can help detect excessive heating at an early stage, ensuring stable and reliable product quality.

Train Heat Treatment Operators

The skill level and responsibility of heat treatment operators play a crucial role in preventing overheating. Comprehensive training and management should be implemented to improve operational skills and ensure adherence to standardized processes.

Conclusion

Overheating is a critical issue in heat treatment. It damages the microstructure, weakens mechanical properties, and increases scrap rates. Preventing excessive heating requires strict temperature control, time management, and proper furnace conditions. With the right approach, manufacturers can maintain material quality and avoid costly waste. Need expert advice? Get in touch with Alloyxpert today!

FAQs

Can overheated metal be fixed?

No. Overheating causes irreversible structural damage. Once the grain boundaries melt, the material loses strength and cannot be restored.

What is the difference between overheating and burning?

Overheating melts grain boundaries, while burning oxidizes and depletes alloying elements, making the metal brittle. Burning is usually more severe than overheating.

Which metals are most prone to overheating?

Steels with high carbide content, such as high-speed steels (e.g., W18Cr4V), are at higher risk due to carbide dissolution at excessive temperatures.

Read More:

15 Common Heat Treatment Misconceptions Debunked

How to Identify Metal Cracks in Raw Material, Heat Treatment, and Forging?