Introduction

Low alloy steel is a versatile and essential material in many industries. Known for its high strength, weldability, and cost-effectiveness, it offers unique advantages that make it a preferred choice in various applications. This guide will delve into its composition, properties, grades, applications, and how it compares to carbon steel.

What is Low Alloy Steel?

Low alloy steel typically contains small amounts of alloying elements such as chromium, nickel, and molybdenum. These elements enhance its mechanical properties without significantly increasing costs. The alloying elements improve various attributes, including hardness, strength, and resistance to wear and corrosion. These enhancements make low alloy steel suitable for many demanding applications.

What Are the Common Grades of Low Alloy Steel?

Known for good weldability and strength, 4130 low alloy steel is commonly used in aerospace and motorsport applications. Its ability to be easily welded and machined makes it a favorite in these industries. This grade is also known for its excellent toughness and resistance to fatigue, making it ideal for high-stress applications.

-

4140 Low Alloy Steel

4140 low alloy steel offers high toughness and wear resistance, suitable for forging applications. It is often used in the manufacture of heavy-duty machinery parts, shafts, and gears. This grade is also heat-treatable, allowing it to achieve a wide range of mechanical properties.

-

4340 Low Alloy Steel

4340 low alloy steel provides excellent strength and toughness, widely used in heavy-duty industrial applications. This grade is ideal for high-stress parts such as axles, crankshafts, and other critical components in machinery. Its superior hardenability and ability to maintain strength at high temperatures make it suitable for aerospace applications as well.

What Are the Properties of Low Alloy Steel?

-

High Strength

Low alloy steel provides exceptional strength, making it suitable for demanding applications. This strength comes from the alloying elements that enhance its hardness and durability. High strength is particularly beneficial in structural applications where the material needs to support heavy loads without deforming.

-

Versatility

The mechanical properties of low alloy steel can be tailored to fit various needs, enhancing its adaptability. This versatility makes it an excellent choice for many different industries and applications. By adjusting the heat treatment and alloying elements, manufacturers can produce low alloy steel with specific properties suited for unique applications.

-

Heat Resistance

Low alloy steel can withstand moderate heat, making it suitable for high-temperature applications. This resistance is crucial in industries where materials are exposed to elevated temperatures regularly. For example, low alloy steel is often used in the construction of boilers and pressure vessels.

-

Moderate Corrosion Resistance

Low alloy steel offers good resistance to corrosion in non-aggressive environments. While not as resistant as stainless steel, it still provides adequate protection against rust and corrosion. This makes it suitable for applications where the material is exposed to weathering or moisture but not highly corrosive chemicals.

What Are the Advantages of Low Alloy Steel?

-

Cost-Effectiveness

Low alloy steel is more affordable than high-alloy steels, providing an economical solution for many industries. Its lower cost does not compromise its performance, making it a popular choice for cost-sensitive projects. The balance of cost and performance makes low alloy steel a practical choice for both large-scale industrial applications and smaller-scale manufacturing.

-

Weldability

The excellent weldability of low alloy steel makes it ideal for fabrication and construction projects. This property ensures that the steel can be easily joined without losing its strength or integrity. Weldability is particularly important in industries such as automotive and construction, where components need to be assembled efficiently.

-

High Strength-to-Weight Ratio

Low alloy steel’s strength-to-weight ratio makes it ideal for applications requiring strong yet lightweight materials. This characteristic is particularly important in the automotive and aerospace industries, where reducing weight without sacrificing strength is crucial. The high strength-to-weight ratio also contributes to fuel efficiency in vehicles and aircraft.

What Are the Applications of Alloy Steel?

-

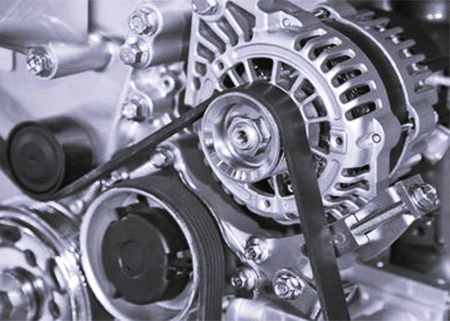

Automotive Industry

Low alloy steel is used in manufacturing various automotive parts for its strength and durability. Components such as gears, crankshafts, and connecting rods benefit from the material’s properties, enhancing vehicle performance and longevity. The automotive industry relies on low alloy steel for its ability to withstand the stresses and strains of everyday use while maintaining a lightweight profile.

-

Construction Industry

Low alloy steel is ideal for structural components in buildings and bridges. Its strength and versatility make it a preferred material for construction projects that require durable and reliable materials. In construction, low alloy steel is often used for beams, columns, and reinforcing bars, providing the necessary support for large structures.

-

Energy Sector

Low alloy steel is utilized in pipeline systems due to its weldability and strength. The material’s ability to withstand high pressures and temperatures makes it suitable for transporting oil and gas. In the energy sector, low alloy steel is also used in the construction of power plants, where its resistance to heat and corrosion is essential.

-

Defense Industry

Low alloy steel is employed in military equipment for its toughness and reliability. The material’s ability to withstand extreme conditions makes it suitable for manufacturing various defense components. In the defense industry, low alloy steel is used to produce armor, weapon systems, and military vehicles, providing the necessary protection and durability.

What Is The Difference Between Low Alloy Steel And Carbon Steel?

-

Composition Differences

Low alloy steel contains higher amounts of alloying elements compared to carbon steel. These additional elements enhance the material’s mechanical properties, making it more suitable for specific applications. The presence of alloying elements such as chromium and nickel in low alloy steel distinguishes it from carbon steel, which primarily contains iron and carbon.

-

Performance Differences

Low alloy steel offers superior strength and toughness over carbon steel, making it suitable for more demanding applications. The enhanced properties of low alloy steel allow it to perform better under high-stress conditions. In comparison, carbon steel may be more prone to deformation and failure in extreme environments.

Conclusion

Low alloy steel is a crucial material in various industries due to its balance of cost, strength, and versatility. Its various grades and properties make it adaptable for multiple applications, from automotive to construction and beyond. Understanding the composition, properties, and applications of low alloy steel helps in selecting the right material for specific needs, ensuring optimal performance and cost-effectiveness.

FAQs

-

What Are the Main Benefits of Low Alloy Steel?

Low alloy steel offers a balance of strength, weldability, and cost-effectiveness, making it suitable for various applications. Its ability to maintain high performance while remaining affordable makes it a preferred choice in many industries.

-

What is The Difference Between Low Alloy Steel And Stainless Steel?

While stainless steel offers superior corrosion resistance, low alloy steel is more cost-effective and provides adequate strength and versatility for many applications. The choice between low alloy steel and stainless steel depends on the specific requirements of the application, such as the need for corrosion resistance or budget constraints.

-

What Industries Commonly Use Low Alloy Steel?

Low alloy steel is widely used in automotive, construction, energy, and defense industries due to its excellent mechanical properties. Its versatility and reliability make it a go-to material for applications requiring durability and strength.