Table of Contents

Introduction

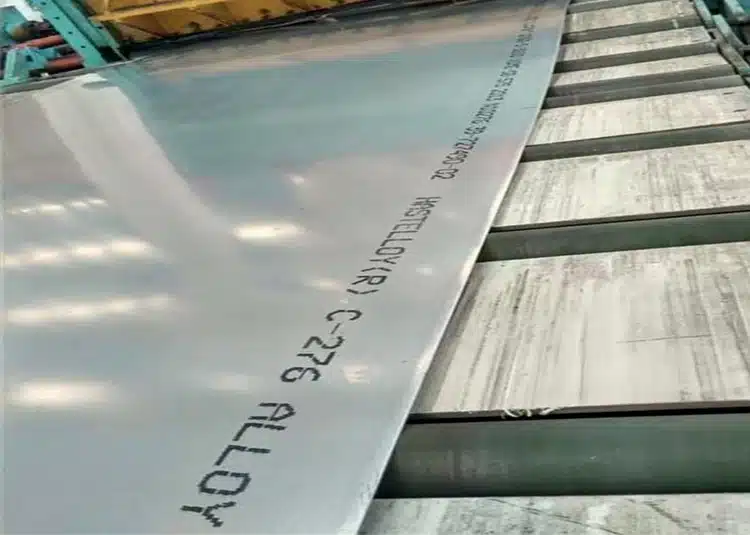

Hastelloy C276 (UNS N10276) is a versatile nickel-molybdenum-chromium alloy known for its exceptional corrosion resistance in harsh environments. With excellent durability in aggressive conditions, Hastelloy C276 is a top choice for environments exposed to strong acids and high temperatures. In this article, we will explore its key properties, industrial uses, and comparison with other alloys in detail.

What Is Hastelloy C276?

Hastelloy C276, also known as UNS N10276, is a nickel-molybdenum-chromium alloy known for its excellent corrosion resistance, especially in harsh chemical environments. It resists pitting, crevice corrosion, and stress corrosion cracking, making it ideal for use in industries like chemical processing, oil and gas, and marine environments where durability in aggressive conditions is essential.

What Are the Key Properties of Hastelloy C276?

Chemical Composition

| Element | Percentage (%) |

| Nickel (Ni) | 57.0 min |

| Molybdenum (Mo) | 15.0 – 17.0 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4.0 – 7.0 |

| Tungsten (W) | 3.0 – 4.5 |

| Cobalt (Co) | 2.5 max |

| Manganese (Mn) | 1.0 max |

| Vanadium (V) | 0.35 max |

| Carbon (C) | 0.01 max |

| Silicon (Si) | 0.08 max |

| Phosphorus (P) | 0.04 max |

ASTM Standard

| Plate, Sheet, Strip | Bar | Seamless Pipe | Welded Pipe | Seamless Tube | Welded Tube |

| ASTM B575 | ASTM B574 | ASTM B622 | ASTM B619 | ASTM B622 | ASTM B626 |

Mechanical Properties

| Property | Value |

| Tensile Strength | 690 MPa (min) |

| Yield Strength (0.2% Offset) | 283 MPa (min) |

| Elongation | 40% (min) |

| Hardness | 100-150 HB |

| Density | 8.89 g/cm³ |

| Melting Range | 1,370-1,390 °C |

Corrosion Resistance

Hastelloy C276 offers exceptional corrosion resistance in both reducing and oxidizing environments, including acids like hydrochloric, sulfuric, and phosphoric. It resists pitting, crevice corrosion, and stress corrosion cracking, making it highly effective in challenging environments such as chemical processing, oil and gas, and marine applications. Its broad resistance to a variety of corrosive agents, including chloride and oxidizing salts, makes it a versatile material for use in harsh industrial conditions.

High-Temperature Performance

Hastelloy C276 retains its strength and corrosion resistance at high temperatures up to 1040°C (1900°F). It is highly resistant to oxidation and carburization in hot environments, making it suitable for applications involving heat and aggressive chemicals. The alloy’s mechanical properties remain stable under thermal stress, ensuring long-term durability in industries like chemical processing, power generation, and waste treatment, where high-temperature performance is crucial.

What Are the Applications of Hastelloy C276?

Marine Industry

Due to its superior resistance to seawater corrosion, Hastelloy C276 is widely used in marine environments for components such as:

- Shafts and propellers

- Pumps and valves

- Heat exchangers and piping systems

Chemical Processing

Hastelloy C276 excels in handling various acids, making it a top choice for chemical plants. Common applications include:

- Reactors and pressure vessels

- Heat exchangers and evaporators

- Piping systems

Oil and Gas Industry

The oil and gas sector values Hastelloy C276 for its toughness and corrosion resistance. It’s frequently used in:

- Oil drilling equipment

- Pipelines exposed to harsh environments

- Heat exchangers in refineries

Other Key Applications

Hastelloy C276 is also widely used in:

- Pollution control systems (scrubbers, stack liners)

- Power generation (heat exchangers)

- Pharmaceutical equipment (reactors, piping)

Hastelloy C276 vs. Other Alloys

When comparing Hastelloy C276 to other alloys, its standout feature is superior corrosion resistance in harsh environments. It is often compared to widely used alloys like Inconel 625, Monel 400, and Incoloy 825, each offering specific strengths.

Hastelloy C276 vs Inconel 625

Hastelloy C276 offers better corrosion resistance in harsh chemical environments, while Inconel 625 is superior for high-temperature applications due to its excellent oxidation resistance. C276 is ideal for chemical processing, whereas 625 is commonly used in aerospace and power generation.

Hastelloy C276 vs Monel 400

Hastelloy C276 excels in resisting a wider range of corrosive chemicals, including strong acids, compared to Monel 400, which is more effective in seawater and alkaline environments.

Hastelloy C276 vs Incoloy 825

Hastelloy C276 provides superior resistance to aggressive chemicals, including chlorides, while Incoloy 825 is more suitable for sulfuric acid environments. C276 is preferred for more extreme conditions.

Conclusion

Hastelloy C276 stands out for its remarkable corrosion resistance, high-temperature stability, and mechanical strength, making it a go-to material in industries like chemical processing, oil and gas, marine, pollution control, and power generation. Its ability to resist a wide range of corrosive agents ensures its longevity and reliability in challenging environments. For reliable, high-quality Hastelloy C276 materials, trust AlloyXpert to meet your needs. Contact us today to get started on your next project!

Read More:

Hastelloy C276 vs Monel 400: The Key Differences You Should Know