Table of Contents

Introduction

Hastelloy C276 vs Monel 400 are both popular in industries requiring high corrosion resistance and durability. Hastelloy C276 offers superior protection in aggressive chemical processing and high-temperature environments. On the other hand, Monel 400 excels in marine applications and moderate corrosion environments. This article compares these alloys in terms of chemical composition, corrosion resistance, and application to help you choose the right material for your industrial needs.

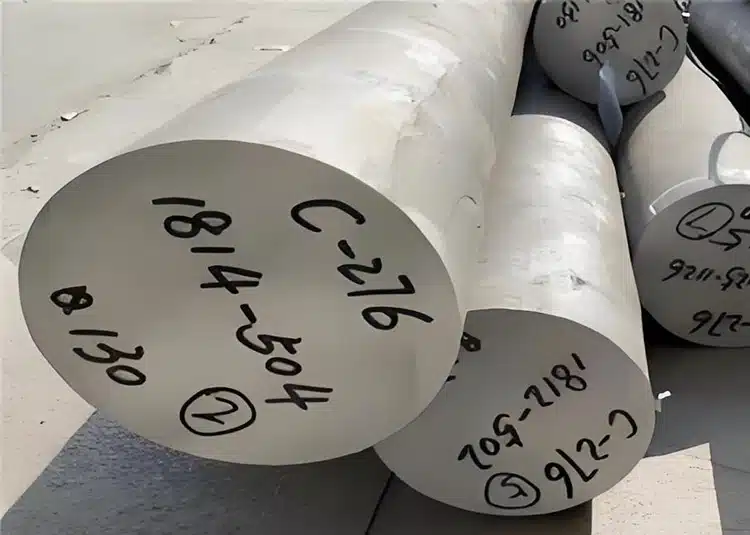

What is Hastelloy C276?

Hastelloy C276 (UNS N10276) is a nickel-chromium-molybdenum superalloy developed by Haynes International in 1960. It is highly resistant to a wide range of corrosive chemicals and extreme temperatures, making it ideal for industries such as chemical processing, marine engineering, and power generation. Its low carbon and silicon content helps prevent welding issues, offering reliable performance in welded applications. Despite its higher cost, Hastelloy C276’s durability and resistance to acids, heat, and stress make it a long-term cost-effective solution in demanding environments like aerospace and nuclear engineering.

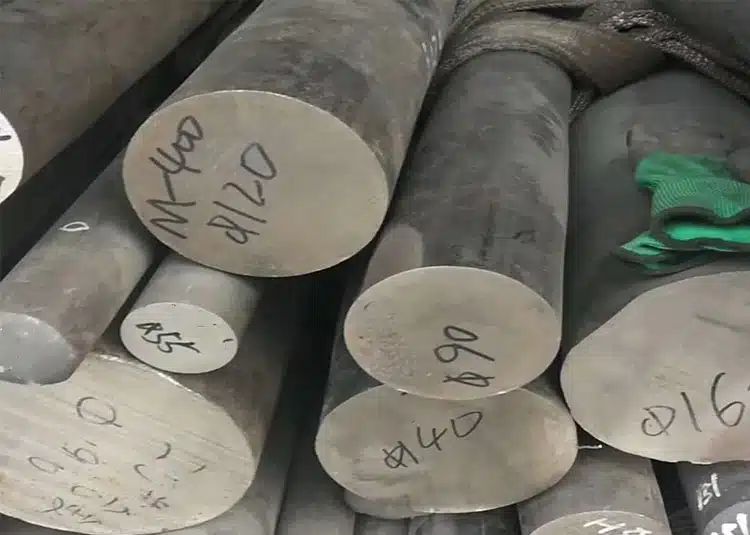

What is Monel 400?

Monel 400 (UNS N04400) is a nickel-copper alloy composed of about 67% nickel and 23% copper. It offers high strength, toughness, and excellent corrosion resistance, particularly in seawater and acidic environments. This solid-solution alloy can only be hardened by cold working and is widely used in chemical processing, marine engineering, and aerospace industries. Monel 400’s versatility and durability, combined with ease of fabrication, make it a cost-effective choice for demanding applications.

What are the Differences Between Hastelloy C276 and Alloy 400?

Hastelloy C276 vs Monel 400 ASTM Standards

| Property | Hastelloy C276 (Hastelloy C276) | Monel 400 |

| ASTM for Seamless Pipe & Tube | ASTM B622, ASTM B983 | ASTM B165, ASTM B829 |

| ASTM for Welded Pipe | ASTM B619 | ASTM B725, ASTM B775 |

| ASTM for Welded Tube | ASTM B626 | ASTM B730, ASTM B751 |

| ASTM for Rod, Bar, and Wire | ASTM B574 | ASTM B164 |

| ASTM for Plate, Sheet, and Strip | ASTM B575 | ASTM B127 |

Hastelloy C276 vs Monel 400 Chemical Composition

| Element | Hastelloy C276 | Monel 400 |

| Nickel (Ni) | 57.0% min | 63.0% min |

| Chromium (Cr) | 14.5-16.5% | – |

| Molybdenum (Mo) | 15.0-17.0% | – |

| Iron (Fe) | 4.0-7.0% | 2.5% max |

| Copper (Cu) | 0.5% max | 28-34% |

| Tungsten (W) | 3.0-4.5% | – |

| Cobalt (Co) | 2.5% max | – |

| Manganese (Mn) | 1.0% max | 2.0% max |

| Silicon (Si) | 0.08% max | 0.5% max |

| Carbon (C) | 0.01% max | 0.3% max |

| Sulfur (S) | 0.03% max | 0.024% max |

Hastelloy C276 vs Monel 400 Corrosion Resistance

| Environment | Hastelloy C276 | Monel 400 |

| Seawater | Excellent resistance to pitting and crevice corrosion (up to 40°C) | Excellent resistance but may corrode in high-velocity currents (up to 60°C) |

| Oxidizing Acids (e.g., Nitric Acid) | Resistant up to 60% nitric acid at ambient temperatures | Limited resistance; susceptible in concentrations above 10% |

| Reducing Acids (e.g., Hydrochloric Acid, Sulfuric Acid) | Outstanding resistance, particularly in diluted hydrochloric acid | Good in diluted sulfuric acid, but limited in hydrochloric acid |

| Chloride-Induced Corrosion (Pitting/Crevice Corrosion) | Resistant in chloride concentrations up to 1,000 ppm | Susceptible to pitting in high chloride environments (above 500 ppm) |

| Alkaline Solutions | Moderate resistance at room temperature | Excellent resistance up to 150°C |

| Hydrofluoric Acid | Limited resistance (less than 10% concentration) | Excellent resistance in all concentrations |

| High-Temperature Environments | Excellent resistance up to 425°C | Limited to temperatures below 315°C (oxidation occurs above this) |

Hastelloy C276 vs Monel 400 Physical Properties

| Property | Hastelloy C276 | Monel 400 |

| Density | 8.89 g/cm³ | 8.80 g/cm³ |

| Melting Point | 1,323-1,371°C (2,415-2,500°F) | 1,300-1,350°C (2,370-2,460°F) |

| Tensile Strength | 690 MPa (100 ksi) | 550 MPa (80 ksi) |

| Yield Strength | 283 MPa (41 ksi) | 172 MPa (25 ksi) |

| Elongation | 40-50% | 40% |

| Thermal Conductivity | 10.2 W/m·K (at 24°C) | 21.8 W/m·K (at 24°C) |

| Electrical Resistivity | 1.24 µΩ·m | 0.51 µΩ·m |

| Hardness (Rockwell B) | 95 | 65 |

Hastelloy C276 vs Monel 400 Mechanical Properties

| Property | Hastelloy C276 | Monel 400 |

| Tensile Strength | 690 MPa (100 ksi) | 550 MPa (80 ksi) |

| Yield Strength | 283 MPa (41 ksi) | 172 MPa (25 ksi) |

| Elongation | 40-50% | 40% |

| Hardness (Rockwell B) | 95 | 65 |

| Modulus of Elasticity | 205 GPa | 179 GPa |

| Fatigue Strength | 275 MPa (40 ksi) | 150 MPa (22 ksi) |

| Impact Toughness | High (resistant to cracking) | High (resistant to cracking) |

Hastelloy C276 vs Monel 400 Thermal Properties

| Property | Hastelloy C276 | Monel 400 |

| Thermal Conductivity | 10.2 W/m·K (at 24°C) | 21.8 W/m·K (at 24°C) |

| Coefficient of Thermal Expansion | 11.2 µm/m·°C (at 20-100°C) | 13.9 µm/m·°C (at 20-100°C) |

| Specific Heat Capacity | 427 J/kg·K (at 25°C) | 427 J/kg·K (at 25°C) |

| Melting Point | 1,323-1,371°C (2,415-2,500°F) | 1,300-1,350°C (2,370-2,460°F) |

| Electrical Resistivity | 1.24 µΩ·m | 0.51 µΩ·m |

Hastelloy C276 vs Monel 400 Temperature Performance

| Property | Hastelloy C276 | Monel 400 |

| Maximum Operating Temperature | Up to 425°C (797°F) | Up to 315°C (600°F) |

| Performance at High Temperatures | Excellent resistance to oxidation and scaling at high temperatures | Limited, tends to oxidize above 315°C |

| Low-Temperature Performance | Maintains strength and corrosion resistance at cryogenic temperatures | High toughness and strength at sub-zero temperatures |

| Thermal Stability | Stable in both high and low temperatures | Stable, but limited at higher temperatures compared to Hastelloy C276 |

Hastelloy C276 vs Monel 400 Weldability and Fabrication

| Property | Hastelloy C276 | Monel 400 |

| Weldability | Excellent; low carbon and silicon content reduce welding issues | Good, but can be more prone to cracking in certain conditions |

| Welding Methods | Suitable for TIG, MIG, and shielded metal arc welding | Suitable for MIG, TIG, and submerged arc welding |

| Pre-Heating Requirements | No pre-heating needed for most welding processes | Typically no pre-heating required, but thicker sections may benefit from it |

| Post-Weld Heat Treatment | Not typically required, but can be performed to relieve stress | Generally not required, but can be beneficial in some applications |

| Formability | Good formability, though harder to work than Monel 400 due to strength | Excellent, easily cold-formed and shaped into complex structures |

| Machinability | Difficult to machine, requires carbide tooling and low speeds | Easier to machine compared to Hastelloy C276, with better performance using standard methods |

Hastelloy C276 vs Monel 400 Applications

Hastelloy C276 Applications:

- Chemical Processing: Piping and vessels handling aggressive acids like sulfuric and hydrochloric acid.

- Pollution Control: Stack liners, ducting, and scrubbers in waste treatment plants.

- Oil and Gas: Equipment exposed to sour gas and offshore environments.

- Aerospace: Components exposed to high temperatures and corrosive atmospheres.

- Power Generation: Heat exchangers, turbines, and reactors for energy systems.

Monel 400 Applications:

- Marine: Propellers, pumps, and piping for seawater exposure.

- Chemical Industry: Acid tanks and handling equipment for mild acidic conditions.

- Aerospace: High-temperature applications such as turbine blades and exhaust systems.

- Oil and Gas: Offshore drilling equipment, valves, and pipelines.

- Electronics: Corrosion-resistant springs, connectors, and electrical components.

Hastelloy C276 vs Monel 400 Price

Hastelloy C276 is more expensive than Monel 400 due to its higher content of costly elements like molybdenum, chromium, and tungsten, which offer superior corrosion and high-temperature resistance. Monel 400, a nickel-copper alloy, is more cost-effective and suited for marine and moderately corrosive environments. While Hastelloy C276’s higher price is justified by its durability in extreme conditions, Monel 400 remains a more affordable option for less demanding applications.

Conclusion

Hastelloy C276 outperforms Monel 400 in highly corrosive and high-temperature environments due to its nickel-chromium-molybdenum composition. Meanwhile, Monel 400, with its nickel-copper makeup, is more cost-effective and excels in marine and moderately corrosive conditions. Selecting the right alloy depends on your specific needs for corrosion resistance, temperature tolerance, and budget. For tailored advice and quotes, reach out to AlloyXpert today!

Read More:

Inconel Alloy 625 VS Incoloy Alloy 825: The Key Differences You Should Know

Inconel Alloy 600 VS Inconel Alloy 601: the Key Differences You Should Know

Inconel 600 VS Incoloy 800: The Key Differences You Should Know

Inconel 718 VS Incoloy 825: The Key Differences You Should Know