Table of Contents

Introduction

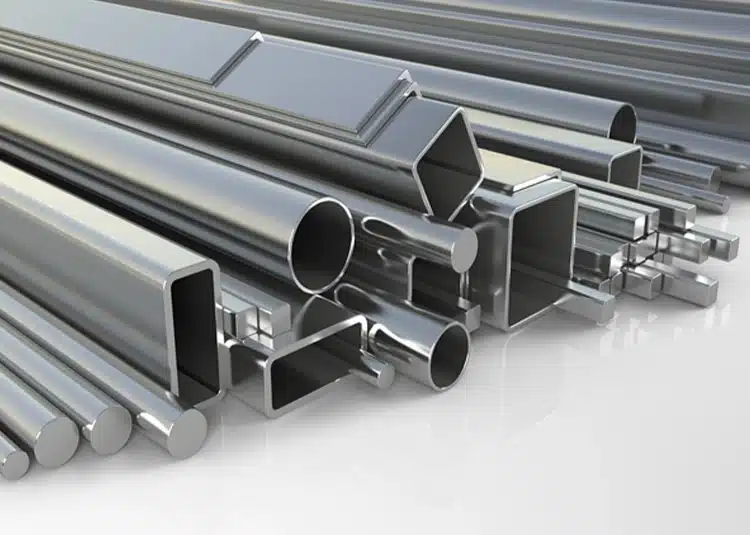

Stainless steel is a widely used material known for its corrosion resistance and strength. Made from iron, chromium, and other elements, it forms a protective layer that prevents rust. Its durability makes it essential in industries like construction, automotive, and food processing. In this guide, we’ll explore the main types of stainless steel, their properties, and how to choose the right one for your needs.

What Are the Major Types of Stainless Steel?

Stainless steel is classified into several types, each with unique characteristics. These types serve different purposes based on their properties, making them ideal for specific applications. Let’s look at the main categories:

Austenitic Stainless Steel

Austenitic stainless steel is the most commonly used type, known for its excellent corrosion resistance and non-magnetic properties. It’s versatile and highly formable, making it suitable for industries like food processing and construction. Popular grades include 304 and 316.

Ferritic Stainless Steel

Ferritic stainless steel offers moderate corrosion resistance and is magnetic. It’s commonly used in automotive exhaust systems and household appliances due to its thermal conductivity and affordability. Grade 430 is the most widely used ferritic steel.

Martensitic Stainless Steel

Martensitic stainless steel is valued for its high strength and hardness, achieved through heat treatment. It’s commonly found in applications like cutlery and surgical instruments where durability is key. Grades 410 and 420 are typical examples.

Duplex Stainless Steel

Duplex stainless steel combines the strengths of austenitic and ferritic types, offering excellent corrosion resistance and high strength. It’s ideal for demanding environments like chemical processing and oil and gas industries, with grade 2205 being a popular choice.

Precipitation-Hardening Stainless Steel

Precipitation-hardening stainless steel provides high strength and good corrosion resistance through heat treatment. It’s used in aerospace and defense applications, where durability under stress is crucial. Grade 17-4 PH is a commonly used variant.

What Are the Key Differences Between Stainless Steel Types?

Stainless steel comes in various types, each offering distinct advantages depending on the application. Below is a quick comparison of the key differences in corrosion resistance, strength, and magnetic properties.

| Type | Corrosion Resistance | Strength (Tensile Strength in MPa) | Magnetic Properties |

| Austenitic | Excellent | 500-700 | Non-magnetic |

| Ferritic | Moderate | 400-600 | Magnetic |

| Martensitic | Moderate | 600-800 | Magnetic |

| Duplex | Excellent | 600-900 | Partially magnetic |

| Precipitation-Hardening | Good | 900-1200 | Non-magnetic |

How Are Different Stainless Steel Types Used in Various Industries?

Stainless steel is used across various industries due to its diverse properties. Here’s how different types are applied:

Austenitic Stainless Steel

Austenitic steel is highly corrosion-resistant and non-magnetic, making it ideal for:

- Food Processing: Used in equipment like storage tanks and piping (Grade 304).

- Construction: Applied in building facades and structures in coastal areas (Grade 316).

Example: In healthcare, Grade 316 is used for surgical instruments and implants due to its non-reactive nature.

Ferritic Stainless Steel

Ferritic steel is magnetic and moderately resistant to corrosion:

- Automotive: Commonly used in exhaust systems and trims (Grade 430).

- Appliances: Found in dishwashers and ovens.

Example: In the automotive industry, Grade 430 is valued for its heat resistance and durability in exhaust systems.

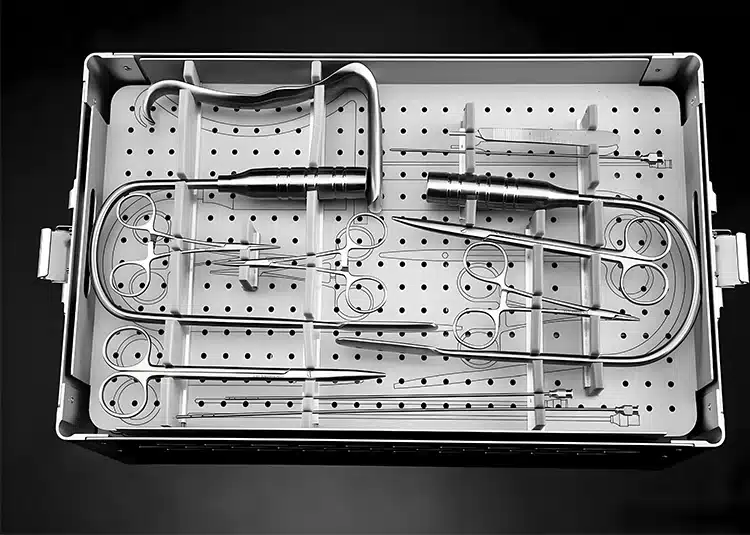

Martensitic Stainless Steel

Martensitic steel is known for its high strength and hardness:

- Cutlery and Tools: Used in knives and scissors (Grades 410, 420).

- Medical Instruments: Ideal for surgical tools due to its toughness.

Example: Surgical instruments like scalpels are made from martensitic steel for its edge retention.

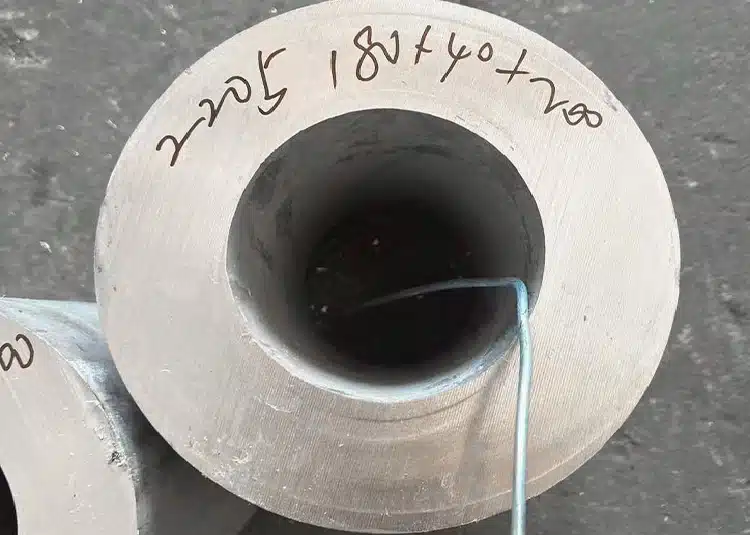

Duplex Stainless Steel

Duplex steel offers a combination of strength and corrosion resistance:

- Oil and Gas: Used in pipelines and offshore platforms (Grade 2205).

- Chemical Processing: Applied in storage tanks and equipment.

Example: Duplex steel is used in oil rigs for its ability to resist harsh, corrosive environments.

Precipitation-Hardening Stainless Steel

This steel type is high in strength and resistant to corrosion:

- Aerospace: Used in turbine blades and structural components (Grade 17-4 PH).

- Defense: Utilized in military equipment for its durability under stress.

Example: Aerospace components benefit from its strength-to-weight ratio in demanding environments.

How To Choose The Right Stainless Steel For Your Needs?

Choosing the right stainless steel depends on factors like corrosion resistance, strength, temperature tolerance, and cost. Here’s a streamlined guide to help you decide:

Corrosion Resistance

For high-corrosion environments such as marine or chemical applications, austenitic stainless steel (304, 316) is ideal due to its excellent resistance. Duplex stainless steel (2205) provides both corrosion resistance and strength, while ferritic stainless steel (430) works well in less demanding environments like appliances.

Strength

If high strength and hardness are necessary, as in tools and surgical instruments, martensitic stainless steel (410, 420) is a good choice. For aerospace or high-stress applications, precipitation-hardening stainless steel (17-4 PH) offers superior strength. For general construction, austenitic stainless steel provides adequate strength.

Temperature Tolerance

For high-temperature environments like exhaust systems, ferritic stainless steel (430) is a reliable option. Austenitic stainless steel (316) works well in both low and high temperatures, making it versatile. Duplex stainless steel offers excellent temperature resistance in harsh conditions.

Cost

Ferritic stainless steel is more affordable due to its lower nickel content, making it a cost-effective option for moderate applications. Austenitic stainless steel (304, 316) is more expensive but necessary for high-corrosion environments. Duplex stainless steel balances cost with performance, making it suitable for demanding but budget-conscious applications.

Conclusion

Stainless steel offers versatility, from austenitic for corrosion resistance to martensitic for strength and duplex for durability. Its wide application in industries like construction, automotive, and healthcare makes it indispensable.

For the best stainless steel solutions, trust AlloyXpert. Our range of high-quality materials ensures you get the right fit for your project. Contact us today to find the perfect stainless steel for your needs!

Read More:

What is the Difference Between 410 and 430 Stainless Steel