Table of Contents

Introduction

Ever wondered why high-carbon steel is strong yet prone to breaking? It’s tough, but when it snaps, it can be sudden and unpredictable. If you’re working with high-carbon steel in automotive parts, tools, or construction, you’ve probably seen how brittle it can get. The problem lies in its structure—more carbon means more hardness but also less flexibility.

Let’s break it down and figure out why carbon-rich steel is a “brittle star” and what can be done to improve its durability.

Does More Carbon Mean Stronger Steel?

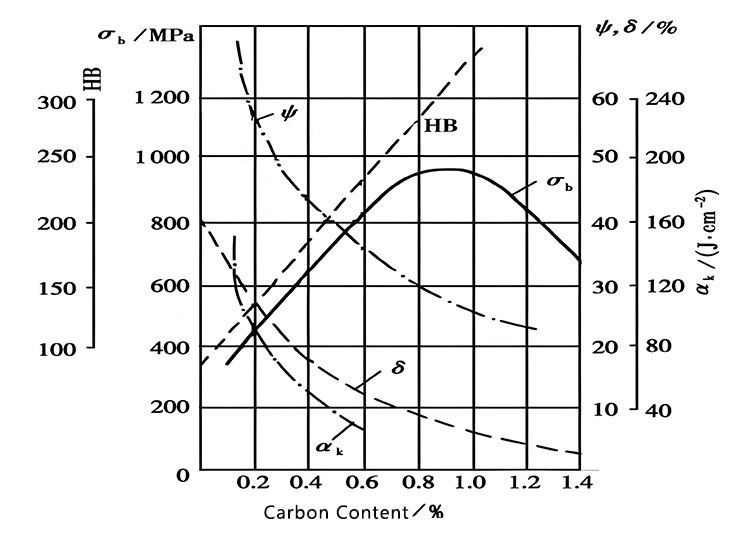

Yes and no. Carbon increases steel’s hardness and strength, but only up to a point. More carbon means more iron carbides (Fe₃C), which make the steel harder but also more likely to crack under stress.

Think of it like glass—it’s hard but shatters easily. High-carbon steel follows a similar pattern. While it resists wear and compression, it loses toughness (the ability to absorb impact) and ductility (the ability to stretch without breaking).

Why Does High-Carbon Steel Crack?

A big reason carbon-rich steel breaks is hydrogen embrittlement. Here’s how it works:

- Iron carbides act like traps for hydrogen. During electrochemical reactions (like corrosion), hydrogen atoms get absorbed into the steel.

- Trapped hydrogen weakens the steel. Instead of bending under stress, the steel cracks.

- Corrosive environments make it worse. If the steel is exposed to moisture or chemicals (especially chlorides), hydrogen embrittlement speeds up.

When steel absorbs hydrogen, it becomes brittle, prone to cracking under stress, and may gradually lose its toughness,making failure more likely over time.

This is why high-carbon steel parts in bridges, pipelines, or high-stress machinery need extra protection.

What Makes Hydrogen Embrittlement Worse?

Some factors make hydrogen embrittlement even more of a problem:

- High stress: The more stress on the steel, the faster cracks appear.

- Corrosion: Exposure to water, salt, or acids increases hydrogen absorption.

- Microstructure: The way iron carbides form in the steel affects how easily hydrogen gets trapped.

Where Does Hydrogen Embrittlement Show Up?

- Automobile parts (springs, gears, shafts)

- Bridges and infrastructure

- Industrial machinery

Without the right treatment, these parts can fail unexpectedly, leading to costly repairs or accidents.

Can Heat Treatment Reduce Brittleness?

Yes. Heat treatment changes the microstructure of high-carbon steel, reducing its brittleness. The goal is to modify the size and distribution of iron carbides, making the steel more resistant to cracking.

Best Heat Treatment Methods

- Tempering: Reduces hardness slightly to improve toughness.

- Annealing: Softens steel and improves flexibility.

- Controlled cooling: Helps prevent too many iron carbides from forming.

Manufacturers use these techniques to improve steel for tools, knives, and industrial parts.

How to Prevent High-Carbon Steel from Cracking?

Since high-carbon steel is brittle, certain steps can reduce the risk of failure:

- Use protective coatings: Plating or coatings (like zinc or nickel) protect against corrosion.

- Apply proper heat treatment: Controls microstructure and reduces brittleness.

- Limit exposure to hydrogen sources: Avoid environments with high moisture, acids, or stress.

- Choose the right steel for the job: If toughness is more important than hardness, lower-carbon steel might be a better choice.

These steps help extend the life of carbon-rich steel parts in demanding applications.

Conclusion

Carbon-rich steel is tough but brittle. It’s strong and wear-resistant but prone to cracking, especially due to hydrogen embrittlement. Proper heat treatment, protective coatings, and careful material selection help reduce failure risks, making it more reliable for demanding applications.

Looking for high-carbon steel solutions? Alloyxpert offers expert-grade materials and treatments to enhance durability. Get in touch today!

FAQs

Why does high-carbon steel break instead of bending?

High-carbon steel has more iron carbides, which make it harder but less flexible. When too much stress is applied, it cracks instead of bending.

Can high-carbon steel be made less brittle?

Yes, through heat treatment like tempering or annealing. This helps balance hardness with toughness.

Is high-carbon steel stronger than stainless steel?

It depends. Carbon-rich steel is harder and better at holding an edge, but stainless steel resists rust and is more flexible.

Read More:

What is Hydrogen Embrittlement and How to Prevent It?