Table of Contents

Introduction

When choosing materials for demanding industrial applications, understanding the differences between Monel and Hastelloy is crucial. Both are high-performance nickel-based alloys, yet each serves distinct purposes due to their unique compositions and properties. This guide compares Monel vs Hastelloy across key factors like composition, corrosion resistance, tensile strength, and melting point to help you choose the best alloy for your needs.

What Is Monel?

Monel is a group of high-performance nickel-copper alloys known for exceptional corrosion resistance and durability in harsh environments. Used extensively in marine, chemical, and oil and gas industries, Monel alloys like Monel 400 and Monel K-500 offer superior resistance to saltwater and acidic conditions, along with excellent mechanical strength and stability under stress.

Chemical Composition

| Monel Grade | Nickel (Ni) % | Copper (Cu) % | Iron (Fe) % | Manganese (Mn) % | Carbon (C) % | Silicon (Si) % | Sulfur (S) % | Aluminum (Al) % | Titanium (Ti) % |

| Monel 400 | 63-70 | 28-34 | 2.5 max | 2.0 max | 0.3 max | 0.5 max | 0.024 max | – | – |

| Monel K-500 | 63-70 | 27-33 | 2.0 max | 1.5 max | 0.25 max | 0.5 max | 0.01 max | 2.3-3.15 | 0.35-0.85 |

Equivalent Materials

| Monel Grade | UNS | Werkstoff | ASTM | AMS | BS | DIN |

| Monel 400 | UNS N04400 | 2.4360 | ASTM B127, B164 | AMS 4675 | BS NA1 | CuNi30Fe |

| Monel K-500 | UNS N05500 | 2.4375 | ASTM B865 | AMS 4676 | BS NA18 | NiCu30Al |

Key Properties

| Monel Grade | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness | Elongation | Thermal Conductivity (W/m·K) | Electrical Resistivity (µΩ·m) | Modulus of Elasticity (GPa) |

| Monel 400 | 8.80 | 1,350 – 1,400 | 550 | 240 | 65 HRB | 35% | 21.8 | 0.510 | 179 |

| Monel K-500 | 8.44 | 1,350 – 1,400 | 965 | 690 | 28 HRC | 20% | 17 | 0.425 | 179 |

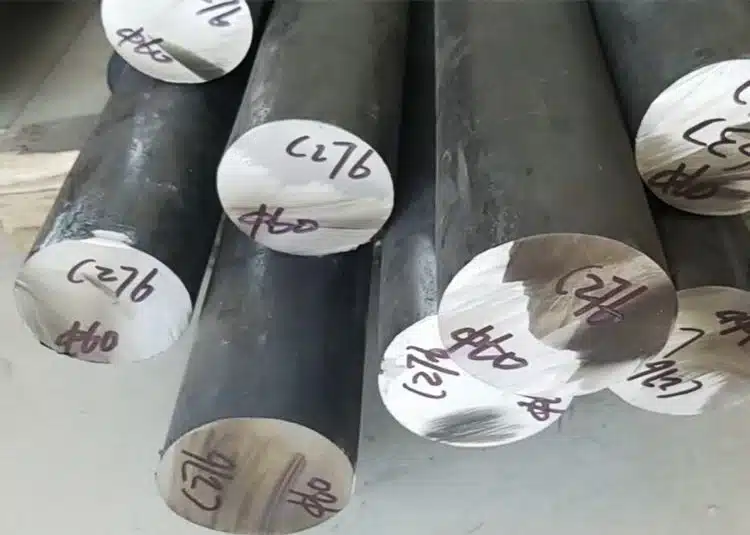

What Is Hastelloy?

Hastelloy is a family of high-performance nickel-based alloys, primarily featuring nickel, molybdenum, and chromium. Known for exceptional corrosion resistance, it excels in harsh environments with both oxidizing and reducing conditions. Commonly used in chemical processing, petrochemical, and aerospace industries, Hastelloy alloys like C276 and X resist pitting, crevice corrosion, and stress corrosion cracking, ensuring durability under extreme conditions.

Chemical Composition

| Hastelloy Grade | Nickel (Ni) % | Chromium (Cr) % | Molybdenum (Mo) % | Iron (Fe) % | Cobalt (Co) % | Tungsten (W) % | Manganese (Mn) % | Silicon (Si) % | Carbon (C) % |

| Hastelloy C-276 | 57 min | 14.5-16.5 | 15-17 | 4-7 | 2.5 max | 3-4.5 | 1 max | 0.08 max | 0.01 max |

| Hastelloy X | 47 min | 20.5-23 | 8-10 | 17-20 | 1.5 max | – | 1 max | 1 max | 0.1 max |

| Hastelloy B-3 | 65 min | 1 max | 28.5-30.5 | 1.5 max | – | – | 3 max | 0.1 max | 0.01 max |

| Hastelloy G-30 | 43 min | 28-31 | 5-6.5 | 15-18 | 5 max | – | 1.5 max | 1.5-2.5 | 0.03 max |

Equivalent Materials

| Hastelloy Grade | UNS | Werkstoff | ASTM | AMS | DIN |

| Hastelloy C-276 | UNS N10276 | 2.4819 | ASTM B575 | AMS 5763 | NiMo16Cr15W |

| Hastelloy X | UNS N06002 | 2.4665 | ASTM B435 | AMS 5536 | NiCr22FeMo |

| Hastelloy B-3 | UNS N10675 | 2.4600 | ASTM B333 | – | NiMo28 |

| Hastelloy G-30 | UNS N06030 | 2.4603 | ASTM B582 | – | NiCr30FeMo |

Key Properties

| Hastelloy Grade | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness | Elongation (%) | Thermal Conductivity (W/m·K) | Electrical Resistivity (µΩ·m) | Modulus of Elasticity (GPa) |

| Hastelloy C-276 | 8.89 | 1,370 – 1,400 | 690 | 283 | 85 HRB | 40 | 10.2 | 1.24 | 205 |

| Hastelloy X | 8.22 | 1,350 – 1,400 | 750 | 345 | 88 HRB | 30 | 11.2 | 1.29 | 220 |

| Hastelloy B-3 | 9.24 | 1,390 – 1,430 | 760 | 350 | 90 HRB | 40 | 9.1 | 1.31 | 210 |

| Hastelloy G-30 | 8.22 | 1,390 – 1,420 | 800 | 380 | 92 HRB | 35 | 7.2 | 1.15 | 215 |

Key Differences Between Monel and Hastelloy

Monel vs Hastelloy Composition

Although both Hastelloy and Monel contain nickel, the proportion and additional elements in each alloy vary. Monel primarily consists of nickel (63-70%) and copper (28-34%), providing excellent resistance in marine and alkaline environments, with smaller amounts of iron, manganese, carbon, and silicon for added strength. In contrast, Hastelloy includes a higher proportion of nickel (typically 47-65%) along with significant amounts of molybdenum and chromium, enhancing its resistance to both oxidizing and reducing conditions, making it suitable for more aggressive chemical environments.

Monel vs Hastelloy Corrosion Resistance

Monel and Hastelloy both excel in corrosion resistance but are suited for different environments. Monel resists corrosion well in marine and mildly alkaline environments, ideal for seawater applications. Hastelloy, with added chromium and molybdenum, excels in aggressive chemical settings, offering superior resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in chloride-rich and highly corrosive environments.

Monel vs Hastelloy Melting Point

Monel and Hastelloy exhibit similar melting points, typically up to 1,350°C (around 2,460°F for Monel and 2,550°F for Hastelloy), with slight variations by grade. While both alloys transition through a “slush” phase, Hastelloy generally offers greater heat resistance than Monel.

Monel vs Hastelloy Yield Strength

The yield strength of a material is the maximum stress it can withstand without permanent deformation, typically measured at a 0.2% offset. For Monel alloys, yield strength ranges from 240 MPa to 690 MPa. In contrast, Hastelloy grades exhibit yield strengths from 283 MPa to 380 MPa at a 0.2% offset.

Monel vs Hastelloy Ultimate Tensile Strength

Monel and Hastelloy alloys differ notably in tensile strength. Monel alloys typically range from 550 MPa to 1,100 MPa, while Hastelloy grades offer higher tensile strength, between 690 MPa and 826 MPa. Tensile strength measures the maximum stress an alloy can endure before failure, ideal for demanding applications across petrochemical, medical, marine, and aerospace industries.

Monel vs Hastelloy Applications

Monel, known for its corrosion resistance, is commonly used in marine, petrochemical, and aerospace applications, especially in seawater equipment and valves. Hastelloy, with superior corrosion and heat resistance, is suited for chemical processing, aerospace, and medical fields, where exposure to harsh chemicals and high temperatures is essential.

Monel vs Hastelloy Price

Monel generally costs less than Hastelloy due to its simpler composition. Hastelloy, with added elements like chromium and molybdenum for enhanced corrosion and heat resistance, commands a higher price, especially in applications demanding extreme durability in harsh environments.

Conclusion

In the comparison of Monel vs Hastelloy, each offering unique benefits across applications. Monel’s resistance to seawater and alkaline environments makes it ideal for marine and petrochemical uses, while Hastelloy’s enhanced corrosion and heat resistance excels in aggressive chemical and high-temperature settings. Selecting the right alloy depends on the specific requirements of your project, including environmental factors and cost considerations.

For expert guidance in choosing the perfect alloy for your needs, explore our range of Monel and Hastelloy products or contact our team for personalized support. Visit our website today!

FAQs

Can Monel and Hastelloy be welded?

Yes, both Monel and Hastelloy alloys are weldable. However, Hastelloy is more compatible with advanced welding techniques, especially in high-temperature or corrosive applications, as it is designed to resist carbide precipitation, which can affect weld integrity in harsh conditions.

What factors should I consider when choosing between Monel and Hastelloy?

When selecting between Monel and Hastelloy, consider the environmental exposure (marine vs. highly corrosive chemicals), temperature requirements, mechanical strength, and budget. Monel is cost-effective for marine environments, while Hastelloy offers superior corrosion and heat resistance for demanding chemical settings.

What maintenance is required for Monel and Hastelloy components?

Both Monel and Hastelloy require minimal maintenance due to their corrosion resistance. However, in highly corrosive environments, it is essential to monitor for pitting or cracking and ensure regular cleaning to preserve their lifespan, especially for components exposed to seawater or harsh chemicals.

Read More:

Inconel vs Monel: A Comprehensive Comparison Guide

Monel VS Stainless Steel: Choosing the Right Alloy for Your Project

Understanding the Differences Between Stainless Steel, Carbon Steel, and Alloy Steel