Table of Contents

Introduction

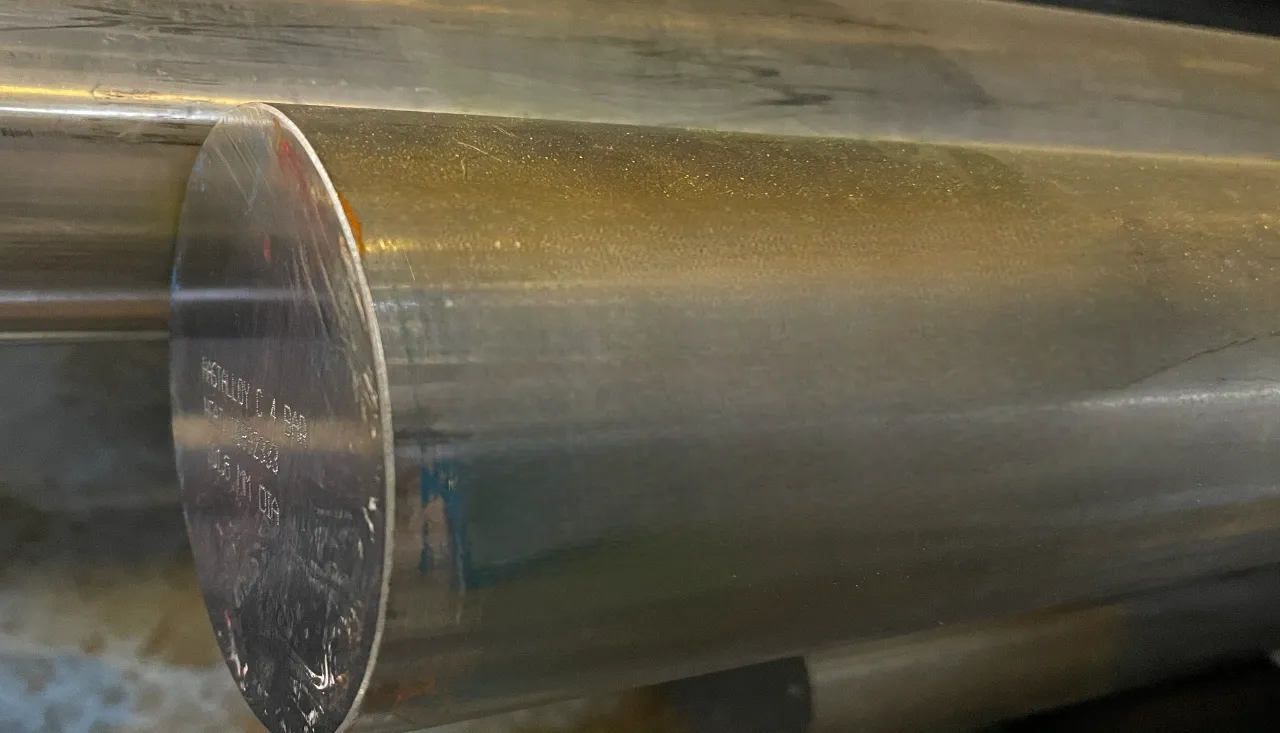

Hastelloy C4 is a nickel-chromium-molybdenum alloy designed for high-temperature corrosion resistance and thermal stability. It is widely used in chemical processing, aerospace, and power generation due to its ability to withstand extreme environments.

In this article, we’ll discuss Hastelloy C-4, its key properties, industrial applications, and how it compares to other corrosion-resistant alloys.

What is Hastelloy C-4?

Hastelloy C-4 (UNS N06455) is a nickel-based superalloy designed for high-temperature and chemically aggressive environments. It offers exceptional resistance to oxidation, pitting, and stress corrosion cracking, making it ideal for industries requiring durable materials. With a low carbon content, it minimizes carbide precipitation, ensuring better weldability and thermal stability. This alloy performs well in both oxidizing and reducing conditions, making it a preferred choice for chemical processing, power plants, and aerospace applications.

Hastelloy C-4 Datasheet

Hastelloy C4 Chemical Composition

| Element | Percentage |

| Nickel (Ni) | 65% min |

| Chromium (Cr) | 14-18% |

| Molybdenum (Mo) | 14-17% |

| Iron (Fe) | 3% max |

| Cobalt (Co) | 2% max |

| Carbon (C) | 0.01% max |

| Silicon (Si) | 0.08% max |

| Manganese (Mn) | 1% max |

| Phosphorus (P) | 0.025% max |

| Sulfur (S) | 0.01% max |

Hastelloy C-4 ASTM Specification

| Standard | Description |

| ASTM B575 | Sheet and Plate |

| ASTM B619/B622 | Seamless Pipe and Tube |

| ASTM B626 | Welded Pipe and Tube |

Hastelloy C4 Mechanical Properties

| Property | Value |

| Tensile Strength | 690 MPa |

| Yield Strength | 283 MPa |

| Elongation | 50% |

| Hardness | 87 HRB |

Hastelloy C-4 Physical Properties

| Property | Value |

| Melting point | 1370–1410°C |

| Density | 8.64 g/cm³ |

| Thermal Conductivity | 10.1 W/m·K |

| Electrical Resistivity | 1.28 μΩ·m |

| Coefficient of Expansion | 12.4 μm/m·°C |

Hastelloy C4 Corrosion Resistance

| Environment | Corrosion Rate (mm/year) | Notes |

| Sulfuric Acid (10%) at 80°C | 0.002 | Excellent resistance |

| Hydrochloric Acid (5%) at 60°C | 0.004 | Minimal attack |

| Phosphoric Acid (20%) at 100°C | 0.001 | Highly stable |

| Seawater at 25°C | 0.0005 | Outstanding marine corrosion resistance |

| Oxidizing Conditions (Nitric Acid 10% at 90°C) | 0.003 | Good oxidation resistance |

| Reducing Conditions (Hydrogen Sulfide 5% at 70°C) | 0.002 | Strong resistance to sulfide attack |

Hastelloy C-4 Fabrication and Heat Treatment

| Process | Temperature/Specification | Notes |

| Solution Annealing | 1065–1140°C | Followed by rapid quenching to avoid carbide precipitation. |

| Hot Working | 900–1200°C | Recommended for forming; cooling should be rapid. |

| Cold Working | Room Temperature | Improves strength but may require intermediate annealing. |

| Machining | Low cutting speeds, carbide tools | High work hardening rate; lubrication essential. |

| Welding | GTAW (TIG), GMAW (MIG) | Use nickel-based fillers (ERNiCrMo-4) and maintain low interpass temperatures (<100°C). |

What Are the Advantages of Hastelloy C-4?

- Excellent Thermal Stability: Maintains mechanical properties up to 1038°C, making it ideal for high-temperature applications.

- Superior Corrosion Resistance: Resists pitting, crevice corrosion, and stress corrosion cracking in aggressive chemical environments.

- High Weldability: Can be welded using standard processes such as TIG and MIG with minimal risk of carbide precipitation.

- Stress Corrosion Cracking Resistance: Performs well under high mechanical stress, ensuring long service life in extreme conditions.

What is Hastelloy C-4 Used For?

- Chemical Processing: Reactors, Heat Exchangers, Distillation Columns, Scrubbers, Piping Systems, Storage Tanks.

- Aerospace & Marine: Gas Turbines, Exhaust Ducts, Afterburner Components, Combustion Liners, Heat Shields, Seawater Piping.

- Power Generation & Nuclear: Nuclear Fuel Reprocessing, Boiler Tubes, Flue Gas Desulfurization, Superheater Tubes, Cooling Systems.

How Does Hastelloy C-4 Compare to Other Alloys?

Hastelloy C4 vs C276

Hastelloy C4 and Hastelloy C276 are both nickel-chromium-molybdenum alloys with excellent corrosion resistance, but they have distinct applications. C4 excels in thermal stability and weldability for high-temperature processes, while C276 offers superior resistance to aggressive chemicals like ferric and cupric chlorides. C4 suits high-heat conditions, whereas C276 is ideal for extreme chemical exposure.

Hastelloy C-4 vs Inconel 625

Hastelloy C-4 and Inconel 625 are both nickel-based alloys, but they serve different purposes. C-4 excels in acidic environments for chemical processing, while Inconel 625 offers superior strength and oxidation resistance for aerospace and marine use. Choose C-4 for chemical corrosion resistance and 625 for high-stress, high-temperature applications.

Conclusion

Hastelloy C4 is a high-performance alloy offering thermal stability, corrosion resistance, and excellent weldability. With its superior ability to withstand oxidizing and reducing environments, C-4 remains a top choice for demanding industries requiring long-term durability.

Need a reliable Hastelloy C4 supplier? Contact Alloyxpert today for more details!

FAQs

What is the main advantage of Hastelloy C-4?

Hastelloy C-4 provides excellent resistance to oxidation and chemical corrosion, making it ideal for high-temperature environments.

Can Hastelloy C-4 be welded easily?

Yes, Hastelloy C-4 is highly weldable with proper filler metals and controlled interpass temperatures.

What industries benefit most from Hastelloy C-4?

Industries such as chemical processing, power generation, and aerospace rely on Hastelloy C-4 for its durability and corrosion resistance.

Read More:

What is C276 Hastelloy (UNS N10276)?