Table of Contents

Introduction

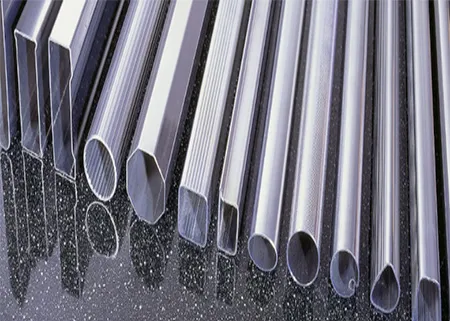

Blog will focus on the properties and standards of the tube stainless steel 316L. It is very tough and resistant to corrosion. This is an alloy of Cr, Ni, and Mo; the tensile strength is 485 MPa.

Here you’ll find the standards, finishes as well as the applications of 316L steel tubes. Read more for details.

What is Tube Stainless Steel 316L?

Tube stainless steel 316L is widely used in many things. It is very strong and does not corrode easily. This steel contains very low amount of carbon. The chromium content is 16 percent. Nickel is 10%.

That makes it last longer. They also add molybdenum, which is 2%. The tensile strength is 485 MPa. It has an elongation of 40%. It exhibits good resistance to corrosion in chloride conditions. 316L is utilized in marine parts.

Why Should You Choose Tube Stainless Steel 316L?

It is recommended that you select tube stainless steel 316L given that it is hard, strong, and does not corrode easily. Here are its features.

High Durability

Tube stainless steel 316L is highly durable. It resists corrosion well. This tube is capable of withstanding a pressure of up to 101.3 MPa. They do not break when they are under pressure.

Containing chromium (Cr), nickel (Ni), and molybdenum (Mo), it is hard. The design also involves welding that is perhaps the most detailed. Consumers use 316L steel in industrial machines for durability.

It is favored by engineers due to its long life. Higher durability indicates that it is effective for extended periods only.

Excellent Strength

Tube stainless steel 316L is very strong. The tensile strength is 580 MPa. This tube is ideal for rough use. Engineers trust its strength. It contains molybdenum (Mo) for enhanced strength.

They remain strong in hard jobs. The chromium (Cr) makes it even stronger. It is widely used in many industries for challenging operations. It is a favorite because of excellent strength. It is useful in many areas due to its construction.

Superior Weldability

Tube stainless steel 316L is weldable. It has 2-3% molybdenum (Mo). This makes it easy for welders to join the pieces together. It maintains its strength after the welding process.

The low C content prevents carbide issues. Sciences like its strong welds. Weldability indicates that work will be done faster. Welders say good things about it. This tube’s weldability ensures that structures remain rigid. It assists in many jobs due to its easy welding.

Non-Magnetic

Tube stainless steel 316L does not respond to magnetic field. It contains a lot of nickel (Ni) and chromium (Cr). This is good for electronics. They do not tamper with gadgets. It keeps machines safe.

The tube is steady at various temperatures. Non-magnetic properties make it useful. This tube does not compromise on essential gears. It works well in special jobs.

High-Temperature Resistance

Tube stainless steel 316L is resistant to heat. This tube operates up to 870°C. It is utilized by engineers in boilers and heaters. It is stabilized by chromium (Cr) and nickel (Ni). High-heat jobs need it.

It halts scaling and rusting. The tube remains strong at high temperatures. Some industries rely on it for hot locations. It also works well in high temperatures. Its ability to withstand high temperatures makes it very useful.

What Are The 316L Standards?

Standards for 316L guarantee its quality and safety. Understanding them enables you make a better decision as per your needs.

Industry Association Standards

ASTM

Tube stainless steel 316L complies with ASTM specifications. This means that the Cr content of it is 16%. Molybdenum makes up 2%. Carbon levels remain low, below 0.03%. Nickel is added and makes 10%.

ASTM prescribes tests for tensile strength, elongation, and yield. They make certain it has a tensile strength of 25% elongation. Tubing has to undergo tests for pressure for safety reasons. This guarantees durability.

ISO

Stainless steel 316L tube complies with ISO requirements. Chromium content is fixed at 17%. Nickel stands at 12%. Carbon is regulated below 0.02%. Molybdenum levels reach 3%. ISO insists on accurate measurements of dimension. Other tests that are equally important are the hardness tests.

Tubes should demonstrate high resistance to corrosion. These structures have to be able to withstand stress without failure. Quality control is strict.

EN

Tube stainless steel 316L is according to the standard of EN. This mandates 18% chromium. Nickel comprises 11%. Carbon limit is 0.01%. Molybdenum reaches 2.5%.

Some of the EN standards are mechanical tests. Tensile strength has to be determined. They measure for 20% elongation. Tubes undergo bending tests. Pitting resistance is confirmed. This ensures reliability.

ASME

Stainless steel 316L tube complies with ASME standards. Chromium content is 16.5%. Nickel stands at 11%. Carbon is set to 0.025%. Molybdenum is 2.7%. ASME requires hydrostatic tests.

Tensile properties are critical. Elongation should be 30%. Yield strength is evaluated. Tubes must resist pressure. This guarantees performance.

BPVC

Tube stainless steel 316L meets the requirements of BPVC. Chromium is 16.5%. Nickel is 12%. Carbon maxes at 0.03%. Molybdenum reaches 3%. BPVC emphasizes pressure testing.

Tubes require high tensile strength. Elongation should exceed 25%. Yield strength is checked. Tubes must withstand stress. This ensures safe operation.

GB

Tube stainless steel 316L complies with the GB standard. Chromium content is 16%. Nickel is 11%. The limit of Carbon is 0.02%. Molybdenum reaches 2%. GB involves very close control of dimensions.

Tensile tests are performed. Elongation must be 28%. Yield strength is measured. Tubes must resist corrosion. This ensures high quality.

Application Standards

GB 150-1998

This uses 316L tubes with 18% chromium and 10% nickel. They require tensile strength of 205 MPa. The material needs to be resistant to temperatures of 870°C. It ensures 30% elongation.

Thickness of the wall is 6mm Pressure rating is 300 bar. Weld joints should be free from defects. Specifications include corrosion resistance. Specific measurements are referred to in the code. That assists in establishing manufacturing standards.

GB/T 14976

According to GB/T 14976, 316L tubes contain a maximum of 0.03% carbon. They should possess yield strength of not less than 215 MPa. It uses cold drawing. Tubes should resist 890°C.

The wall thickness is in the range of 3-8 mm thickness. The outside diameter should be equivalent to 100mm It should also possess High tensile strength. Seamless welding is mandatory. This ensures no corrosion.

ASME SA240

This standard requires 316L tubes with 16% Mo as they provide 220 MPa tensile strength. Tubes must withstand 900°C. The elongation should be 25%.

Wall thickness is 7mm Tubes should be rated for 200 bar pressure. Welding has to be accurate. Corrosion resistance is crucial. Dimensions must be exact. It includes hardness requirements.

ASTM A240

ASTM A240 uses 316L tubes with 19% Cr and 11% Ni. They require 210 MPa tensile strength. Tubes should handle 850°C. Elongation is 28%. It has up to 5 mm wall thickness.

It has a pressure rating of up to 250 bar. Seamless welding is critical. This ensures no corrosion. Dimensions should be precise. Specifications include hardness values.

EN 10088-2

EN 10088-2 refers 316L tubes with 17% Cr. They require tensile strength of 200 MPa. Tubes should withstand 860°C. Elongation must be 27%.

They are 8 mm thick and have a pressure rating up to 280 bar. Welding should be seamless. This ensures no corrosion. Dimensions must be compatible with standards. It contains specific hardness values.

ISO 15510

The ISO 15510 specifies 316L tubes with 18% Cr. They have to achieve a tensile strength of 215 MPa. Tubes withstand 880°C. Elongation should be 26%.

Thickness of the wall is 4 mm and the pressure is 270 bar. Seamless welding is required. This prevents corrosion. Dimensions are crucial. Hardness levels are also covered in specifications.

JIS G4304

JIS G4304 calls for 316L tubes with 18% Cr and 10% Ni. They require tensile strength of 205 MPa. Tubes should resist 870°C. Elongation is 29%. Wall thickness is 5 mm; pressure rating is up to 310 bar. Welding should be seamless. Corrosion resistance is mandatory. Dimensions must be exact. This includes specific hardness levels”.

DIN 17441

According to DIN 17441, using 316L tubes containing 18% Cr is recommended. They require tensile strength of 200 MPa. Tubes must handle 860°C. Elongation is 28%.

Thickness of the walls is 6mm. The pressure range going up to 260 bar. Seamless welding is essential. Corrosion resistance is crucial. The dimensions must be precise. It includes hardness requirements.

How Does Stainless Steel 316L Differ from Other Grades?

Different SS grades have different advantages. Here’s why 316L stands out from the rest of the steels.

304 Composition

Tube stainless steel 316L contains 16-18% Cr, 10-14% Ni, and 2-3% Mo. The Mo makes it strong and shiny. This metal is suitable for use in areas that are exposed to moisture.

Its parts are strong. Cr helps stop rust. They use 316L in pipes and tanks. It is better than 304 because of Mo. This steel is special.

316 Variants

Tube stainless steel 316L has the following types. One type, 316Ti, contains Ti. This makes it to be strong in heat. Another type is 316N which contains N; this makes it stronger.

These types have different tasks. They assist in special areas. It is used in many things. These types are quite helpful.

Molybdenum Addition

Tube stainless steel 316L has Mo. Mo makes it resistant to salty water. The parts stay good. 2-3% Mo is added. This steel is suitable for sea water environment. It is used in ships. Mo prevents the formation of bad spots. This steel is better with Mo. It lasts a long time.

Chloride Resistance

Tube stainless steel 316L prefers salt water. It has 2-3% Mo. Mo assists aids it to remain shiny in salt. This metal is used in boats. It does not get rusty. They use it in water pipes. This makes it special. It does not harm salt. This steel remains strong and nice.

Cost Analysis

Tube stainless steel 316L is relatively expensive. Mo makes it pricey. It lasts longer. This means less fixing. They are cheaper in the long run. It is used in big projects. The cost can be justified. They select it for difficult tasks. This metal is a good deal. It helps save money.

Magnetic Properties

Stainless steel 316L used in tubes is not magnetic in nature. Its parts remain unaltered. Nothing adheres to it like a magnet. This is good for machines. It is used in computers. This steel is special. It does not pull magnets. This makes it safe. It is also used in thousand of things.

Temperature Limits

Tube stainless steel 316L has affinity with heat. It works up to 800°C. This metal just does not melt. It is used in ovens. The parts stay strong. They use it in hot places. This steel does not fracture. It is hard in heat. The metal is very strong. It is used in many ways.

| Feature | Stainless Steel 304 | Stainless Steel 316 | Stainless Steel 316L | Other Grades |

| Composition | 18% Cr, 8% Ni | 16% Cr, 10% Ni, 2% Mo | 16% Cr, 10% Ni, 2% Mo | Varies |

| Variants | None | 316Ti, 316N | Low Carbon (L) Version | 310, 321, 430 |

| Molybdenum Addition | Absent | Present | Present | Varies |

| Chloride Resistance | Moderate | High | High | Low to High |

| Magnetic Properties | Non-magnetic | Non-magnetic | Non-magnetic | Varies (Magnetic/Non) |

| Temperature Limits | 870°C | 925°C | 925°C | 600°C – 1,100°C |

Table on Stainless Steel 316L Differing from Other Grades!

What Are the Key Properties of Tube Stainless Steel 316L?

Understanding key properties makes you choose the right material that will suit your needs best. Let’s explore them.

Corrosion Resistance

This steel resists rust. It has 2-3% Mo that makes it resistant to corrosion. The Cl does not harm it. Cr at 16-18% forms a protective layer. Ni at 10-14% makes it strong.

It is good in the rough areas. P and C are extremely low, thus explaining the absence of cracks. Tube stainless steel 316L is good for use in saltwater. It is long-lasting.

Tensile Strength

It has a tensile strength of 485 Mega Pascal. It’s very strong. Cr and Ni make it difficult. Yield strength is 170 MPa. It stretches 40 % before it breaks. Cold-working makes it harder.

This metal can withstand high pressure. Tube stainless steel 316L is perfect for heavy work. Mo keeps it strong. It’s great for construction.

Yield Strength

Yield strength is 170 MPA. It does not buckle under pressure. C is low at 0.03%, no cracks. It bends before breaking. This is beneficial in many professions. Cr keeps it strong.

Tubes are good to go when they are loaded. That is why Mo at 2-3% keeps it tough. This steel is right for construction.

Thermal Conductivity

The thermal conductivity is 16 W/m-K. It spreads heat well. Mo and Ni improve thermal characteristics. Cr keeps it strong. Tubes function in hot and cold. Expansion is 16 µm/m-K.

Tube stainless steel 316L does not crack from heat. It is suitable for heat exchangers. This is kept steady by Low C. Heat spreads evenly.

Elongation

Elongation is 40%. It has good elastic properties and does not easily snap. Low C keeps it from snapping. Mo and Ni make it flexible. Cr helps it bend. This is good for forming and welding.

Yield strength is high for stress. Tube stainless steel 316L bends, not breaks. It is useful for sliding components. High stretch means it is tight or difficult.

How to Determine the Correct Dimensions for Stainless Steel 316L Tubes?

This means that choosing the correct dimensions is critical for your project. Here’s how you do it.

Outer Diameter

Use calipers to measure the outer diameter (OD) of tube stainless steel 316L. It can be 12, 20, or 25 OD. This size enables it to fit right. For different tasks, different sizes are useful.

OD makes sure that there is proper passage of fluids. A correct OD maintains everything running smoothly. This aids in the formation of good contacts. OD is important.

Wall Thickness

Tube stainless steel 316L requires the correct wall thickness. It is quantified with a micrometer. Thickness can be 1.0, 1.5 or 2.0. This decides tube strength.

A thicker wall is stronger and can withstand more pressure. The thickness determines how much the tube weighs. Choosing the correct thickness is safe. It is good for many uses.

Length Options

Tube stainless steel 316L is available in various lengths. Standard lengths are 1, 2, and 3. They are also able to do custom lengths. Lengths assist to fit various spaces.

Where possible, cutting to right size is desirable. It avoids waste. Appropriate length enables one to do work effortlessly. Length must be commensurate to the need. It is very helpful.

Standard Tolerances

Tube stainless steel 316L has standard tolerance. Typical tolerances include ±0.5 or ±1.0. This keeps fitting accurate. Good tolerances avoid mistakes.

They ensure that components fit well. This keeps work smooth. Tolerances help with safety. They assist in many tasks. Quality is improved by strict rules.

Custom Specifications

Tube stainless steel 316L for special purposes is an individual project. There are choices for OD, thickness, and length. Wearing spectacles with prescription lenses provides perfect fitting.

It assists in special projects. Different specifications lead to more choices. Some different tolerances can be selected as well. This flexibility helps design. Custom specs are very helpful.

What Types of Finishes are Available for Tube Stainless Steel 316L?

Coatings define the overall outlook and longevity of the tube. Here is the breakdown of the choices.

Polished Finish

A polished finish gives tube stainless steel 316L a shiny look. It employs abrasive belts with grit size 240. It makes the surface smooth and reflective.

It is used in automotive applications, in tools, and in furniture. All the corners are sanded to smoothen them. This finish is very easy to clean. It reduces joint wear. Polished tubes are more suitable for decoration.

Brushed Finish

Tube stainless steel 316L has a brushed matte finish. It uses fine grit belts approximately 120. There are fine lines on the surface. This finish is for concealing fingerprints and scratches.

It is applied in kitchen utensils and lifts. It makes tubes stylish. This finish is durable. Brushed tubes are ideal for heavily used areas.

Mill Finish

Mill finish is the raw or ‘as produced’ finish of tube stainless steel 316L. Made by cold rolling, it reveals the actual steel used. This finish is affordable for the industrial application.

It is used in construction, tanks, and machines. No further processing is required. Mill finish is strong. It is good for places where one does not want to give a classy appearance.

Satin Finish

Satin finish ensures that tube stainless steel 316L has a smooth and dull surface that does not reflect light. It uses a 180-grit belt. It has a smooth feel on the surface and is able to mask scratch lines.

This finish looks sophisticated and is used in medical devices, architectural elements, handrails and the like. It enhances usability. Satin tubes are elegant. They are ideal for nice designs.

Mirror Finish

A mirror finish makes tube stainless steel 316L shiny in appearance. It employs a buffing compound and cloth wheels. The surface becomes as smooth as glass.

They use it in jewelry, in mirrors and in fancy appliances. All the surfaces are cleaned and polished meticulously. This finish brings luxury and awareness. The mirror finished tubes are very smooth. They look amazing.

| Finish Type | Surface Roughness (Ra) | Reflectivity | Corrosion Resistance | Aesthetic Quality | Cost |

| Polished | 0.05-0.1 µm | High | Excellent | High Shine | Medium |

| Brushed | 0.2-0.5 µm | Medium | Good | Matte Look | Low-Medium |

| Mill | 1.0-3.0 µm | Low | Fair | Rough Surface | Low |

| Satin | 0.4-0.6 µm | Medium-Low | Good | Soft Sheen | Medium |

| Mirror | <0.05 µm | Very High | Excellent | Reflective Surface | High |

Table on the Types of Finishes are Available for Tube Stainless Steel 316L!

How to Assess the Quality of Tube Stainless Steel 316L?

Quality assessment helps in maintaining reliability and safety of a product. To check your tubes follow these steps.

Visual Inspection

The 316L tubes should appear shiny. Look for any small openings, chips, or scratches. Take the outside diameter and inside diameter of the tube. The thickness of the walls should be uniform.

Examine weld seams. Look at the color and the luster. They shall conform to ASTM A269 requirements. Inspect the surface closely. This aids in identifying any issues at an early stage.

Ultrasonic Testing

Employ a probe for emitting sound waves. Check for flaws inside. Select frequency to 5 MHZ. Look for echoes on the screen. This shows any issues. Adjust settings for accuracy.

Make sure the tube meets ASTM E213 specifications. This maintains the strength of the tubes. This makes it a good test to ensure quality.

Hydrostatic Testing

Put water into the tube. Seal both ends tight. Exert force on the set pressure level. Look for leaks. Use a pressure gauge. Make sure the tube complies with ASTM A450 specifications.

Check the readings carefully. This test ensures that the tube is capable of withstanding pressure. It tests the strength of the tube.

Certification Review

Check the MTR. Check the chemical composition and concentration. It should conform to ASTM A240 specifications. ISO 9001 certification should be sought. Confirm traceability.

Verify the heat number and batch information. This step confirms quality. Ensure all details match. It assists in identifying the source of the tube.

What Are the Welding Considerations for Tube Stainless Steel 316L?

Correct welding leads to good and strong joints. Here is what you should know.

TIG Welding

Welding uses argon gas. It is suitable for tube stainless steel 316L. Use 70 amps. Tungsten electrode should be sharp. It is made strong by a filler rod. Set polarity to DCEN. The 2% thoriated tungsten is fine.

Clean the weld area. Avoid gaps for precision. Regulate the amount of gas that is being supplied to the fire. Control heat input carefully. Ensure a uniform bead.

MIG Welding

This welding employs the use of a wire feed. Apply shielding gas mix. The wire of 0.035 inch thickness is quite suitable. Set voltage to 19. Keep current steady. Feed using a spool gun.

The contact tip must be compatible. Clean surfaces before starting. Ensure proper gas coverage. They control spatter efficiently. Check for proper penetration. Avoid excess heat input.

Pre-Weld Cleaning

Clean surfaces before welding. Eliminate any oil, dirt and rust from the surface. This ensures strong welds. Use acetone for cleaning. They use wire brushes. Do not bring contaminants to the weld area either. Sandpaper helps remove debris. Store it dry before use. Use clean cloths.

Ensure no residue remains. The surface must be smooth and shiny. Ultrasonic cleaning is effective. Prepare joints properly.

Post-Weld Heat Treatment

That is why heat treatment should make it strong. Anneal at 1900°F. Quench fast after heating. This reduces stress. Prevent cracking. Stabilize the microstructure. Avoid carbide precipitation.

Cooling rate matters. Ensure uniform temperature. Control atmosphere during heating. If required, it should be replaced with an inert gas. Measure the hardness after treatment. Adjust based on results.

Filler Materials

Select appropriate filler material. ER316L is good. Diameter has to be in harmony with the tube. Filler rods add strength. Keep them clean. Store dry. Avoid contamination.

Pair the composition with the tube. Check specs before use. Control feed rate. Ensure proper fusion. Maintain steady arc length. This ensures uniform deposition.

How to Handle and Store Tube Stainless Steel 316L?

The kind of handling and storage determines the condition of the tube. Follow these tips to keep them in top shape.

Proper Handling Techniques

Transport 316L tubes with nylon slings. Do not drag to avoid creating 5μm scratch. Wear gloves to prevent leaving 0.1mm fingerprints. To accommodate more tubes, make use of carts.

Verify the ASTM standard of each tube. Clean tools regularly. Verify MTRs for specifications. Check each batch for 1.4404 homogeneity.

Vertical Storage

Stack 316L tubes vertically on sturdy shelves or stands. They are separated by a 10mm diameter for stability. Make sure that labels display ASTM A312 specifications. Check racks for 200kg capacities. Support bases with wooden blocks. Verify vertical alignment.

Do not place tubes on the ground. Include on each the MTR details. Tops should be covered to avoid contamination by dust. Inspect at least once a month for secured storage.

Horizontal Storage

Lay 316L tubes horizontally on padded racks. Divide according to grade and size. Align PVC end caps. Verify ASTM A270 standards. The contact should be avoided and spacers should be used.

Label with MTRs. Ensure even weight distribution. Avoid stacking above 500kg. Cover with polyethylene sheeting. Inspect weekly for dents. Clean area regularly.

Protection from Contaminants

Encase the 316L tubes in polyethylene film. All of them should be labeled with the ASTM A554 standards. Store them in dry areas. Look for 2mm tears on the film.

Replace if damaged. Clean storage weekly. Examine for presence of 5μm oil. Verify MTRs. Keep away from chemicals. Use HEPA air filters. Maintain clean tools.

Avoiding Moisture

It is recommended that 316L tubes should be stored in dry areas. Package it with 500g of silica gel packets. Inspect for condensation regularly. Verify ASTM A249 standards.

Wrap with VCI paper. Label with MTRs. Ensure room humidity stays below 50%. Check weekly for moisture. Maintain air circulation. Replace desiccants monthly. Use dehumidifiers if necessary.

How to Choose the Right Supplier for Tube Stainless Steel 316L?

Selecting the right supplier is all that matters. This is how you find the best one.

Supplier Credentials

Wuxi Chengjiu Metal has top credentials. We possess ISO 9001 and ASTM certifications. We promise high quality. We appreciate 316L stainless steel tubes.

We guarantee small variability and large inaccuracy. Our ERW and EFW methods are employed. Our reputation shows quality. We meet industry standards.

Quality Certifications

Wuxi Chengjiu Metal has high quality. We are certified to ISO 9001. Our 316L stainless steel tubes conform to EN 10204. For checking, we have PMI. We are certified by TUV and SGS for quality. Our certifications are proof.

Technical Support

We provide great help. For 316L, Wuxi Chengjiu Metal suggests TIG, MIG welding. Our experts elaborate on heat treatment. Proper annealing improves ductility. We support feed rate and speed. CNC machining is precise. We solve problems.

Delivery Times

We are fast. Wuxi Chengjiu Metal provides Just-in-Time delivery option. Our logistics work well. Speedy processing is always a promise. We use tracking systems. On-time delivery is key. Timely delivery is a proof of our reliability. Let’s take a look at how we have been performing.

Cost-Effectiveness

Our prices are great. Products from Wuxi Chengjiu Metal can be purchased in large quantities at discounted prices. Effective production equals good prices. Our pricing is competitive.

We offer value and quality. One of the benefits of long-term contracts is that cost is usually more predictable. We always consider the cost and the performance of the facilities. Verify total cost benefits with us.

Which Applications are Best Suited for Tube Stainless Steel 316L?

There are various uses for 316L because the material possesses special characteristics. This is where it is most effective.

Industrial Piping

Tube stainless steel 316L is best suited for use in industrial piping. It has strength of 240 MPa. This resists rust. Pipes transport heat and pressure. Oil refineries use it.

The wall thickness of the tube is 2.5 mm. It is made with the help of the ASTM standards. Pipes include elbows and tees. It is very solid and could transport liquids effectively.

Marine Hardware

Saltwater likes tube stainless steel 316L. It resists rust. The 310 HB hardness is strong. Boat rails use it. Seamless design lasts long. ASTM marine grade fits underwater. Propeller shafts need this. Durable it helps in increasing the lifespan of the boats.

Medical Equipment

Tube stainless steel 316L is for medical tools. It is biocompatible. Surgical tools and implants employ it. ASTM F138 standards fit this. Non-reactive surface stops germs. High strength, 520 MPa, contributes to accuracy. Stents use this. Easy to clean, it is safe.

Food Processing

Tube stainless steel 316L is for food work. It resists bacteria. Smooth surfaces stay clean. Pipes and containers employ it. It is resistant to acids and salts. Heat systems use it. Tubes are 2.0 mm in thickness. It can be cleaned easily and helps in preservation of foods. FDA approves it.

Conclusion

Tube stainless steel 316L possess high durability, strength, and corrosion resistance. This is because it is appropriate for many industries. Cr, Ni, and Mo make it reliable. For further information and to buy, please visit ALLOYXPERT. It must be strong and versatile to meet many technical requirements. Select it for your next project.

Read More:

Understanding the Differences Between 304 and 316L Stainless Steel Plates