Table of Contents

Introduction

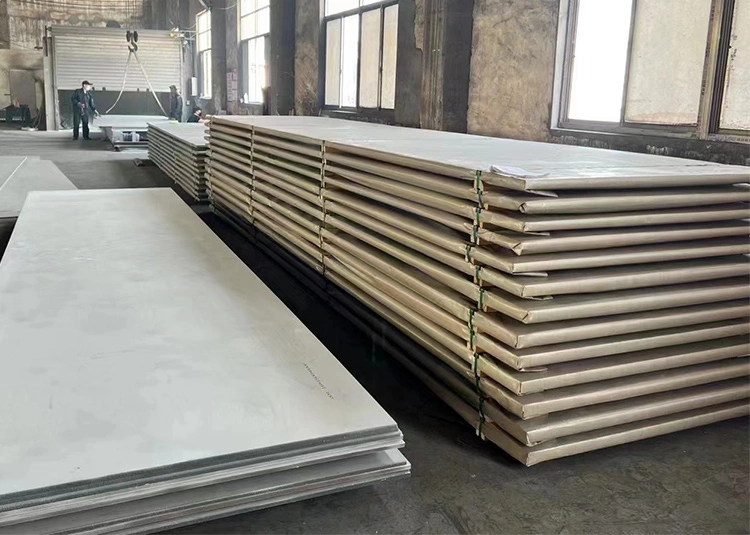

304 stainless steel is celebrated for its corrosion resistance and durability, making it a popular choice across various industries. This guide explores its bending properties—how its composition impacts its flexibility for manufacturing and the best practices for bending this versatile material effectively. We’ll explore key factors that influence its bendability and provide insights to help determine if 304 stainless steel fits your project’s requirements.

What Makes 304 Stainless Steel Unique?

304 stainless steel is one of the most commonly used stainless steel grades due to its excellent corrosion resistance, strength, and versatility. Composed mainly of chromium (18%) and nickel (8%), it is part of the austenitic family, which is known for being non-magnetic and highly formable. Often referred to as “18-8” steel, 304 is ideal for applications requiring both durability and the ability to be easily shaped, such as in food processing equipment, kitchenware, and structural components. Its ability to harden through cold working also makes it suitable for bending and forming processes.

How Do You Bend 304 Stainless Steel?

Bending 304 stainless steel requires careful handling due to its strength and springback tendency. Common techniques include:

V-Bending

The most common method, where a V-shaped die is used to press the metal into the desired angle. This is typically used for sharp bends.

Roll Bending

Ideal for creating large-radius bends, this method involves passing the sheet through rollers to gradually shape it without creating sharp angles.

Air Bending

This process involves partial contact between the sheet and the die, allowing for greater flexibility in achieving various bend angles. However, it requires precise control to avoid material damage due to its high springback tendency.

Factors like sheet thickness and bending radius must be managed to avoid cracking or deformation. Selecting the right method ensures clean, accurate bends while maintaining material integrity.

Where Is 304 Stainless Steel Commonly Used?

304 stainless steel is widely used across industries due to its bendability and versatility. Here are a few real-world examples where its bending capabilities play a crucial role:

Automotive Industry

In automotive manufacturing, 304 stainless steel is bent to create exhaust systems and structural components. Its corrosion resistance makes it ideal for parts exposed to harsh environments. Precision bending ensures that the components fit seamlessly into vehicle designs without compromising strength.

Construction Projects

Many modern architectural designs rely on bent 304 stainless steel for structural elements and cladding. Its ability to withstand weathering and resist corrosion is critical in outdoor applications. For example, stainless steel railings and façade panels are often custom-bent to fit specific designs while maintaining aesthetic and structural integrity.

Food and Beverage Equipment

304 stainless steel is frequently used in bending processes to manufacture kitchen equipment, such as sinks, countertops, and storage units. The material’s hygienic properties and resistance to chemicals make it perfect for bending into complex shapes required in commercial kitchens.

These case studies highlight how 304 stainless steel’s bending properties are applied in different sectors, making it a top choice for projects requiring both flexibility and durability.

What Tools Enhance Bending Efficiency of 304 Stainless Steel?

To achieve the best results when bending 304 stainless steel, using the right tools is essential. The high tensile strength of 304 stainless steel requires specialized equipment that can handle its resistance while maintaining precision. Here are some tools and methods that enhance bending efficiency:

Press Brakes: Press brakes are the most commonly used tools for bending stainless steel. They allow for accurate bends by applying consistent pressure along the metal surface. For 304 stainless steel, hydraulic press brakes are ideal because they offer better control over the bending force required for tougher materials.

Roll Bending Machines: For larger, smooth curves, roll bending machines are preferred. They use a series of rollers to gradually shape the stainless steel without creating sharp angles, ensuring smooth and consistent bends.

Mandrel Benders: For tubing, mandrel benders are highly effective. These machines use an internal support to prevent the tubing from collapsing or wrinkling during the bending process, allowing for high-quality bends, especially in complex shapes.

CNC Bending Machines: CNC (Computer Numerical Control) machines provide precise control over bending angles and force. For complex or repetitive bending tasks, CNC machines ensure accuracy and consistency, especially when dealing with materials like 304 stainless steel that require precision.

Selecting the right tool for the job not only improves bending accuracy but also minimizes material waste and machine wear. By optimizing equipment and techniques, manufacturers can achieve efficient and high-quality bends in 304 stainless steel.

Conclusion

304 stainless steel offers excellent bending properties, combining strength and flexibility. With the right techniques and tools, it can be shaped to meet diverse industrial needs while maintaining durability. Whether for automotive, construction, or kitchen applications, 304 stainless steel is a reliable choice. Ready to start your next project? Visit AlloyXpert to source high-quality 304 stainless steel today!

Frequently Asked Questions

Can 304 stainless steel be easily bent by hand?

Due to its high tensile strength, 304 stainless steel is difficult to bend by hand, especially in thicker gauges. For precise or complex bends, tools like press brakes or mandrel benders are typically needed.

Does bending 304 stainless steel affect its corrosion resistance?

Bending does not significantly affect the corrosion resistance of 304 stainless steel, provided the surface finish is maintained and there is no significant work hardening or surface damage during the process.

How much force is needed to bend 304 stainless steel?

The force required depends on the thickness and type of bend. Thicker sheets require more force, and sharper bends need more precise control to prevent cracking or distortion.

What is springback, and how does it affect the bending process?

Springback occurs when the material tries to return to its original shape after bending. 304 stainless steel, due to its elasticity, tends to spring back more than softer metals, so slight over-bending is necessary to achieve the desired angle.

What tools are best for bending 304 stainless steel?

Common tools include press brakes for precise bends, roll benders for smooth curves, and CNC machines for automated, complex bends. For tubing, mandrel benders are ideal to prevent collapse during bending.

Can 304 stainless steel crack during bending?

Yes, if the bend radius is too tight or if the material is improperly handled, 304 stainless steel can crack. It’s important to follow proper bending guidelines and use appropriate tools to avoid this.

Read More:

Understanding the Differences Between 304 and 316L Stainless Steel Plates