Table of Contents

Introduction

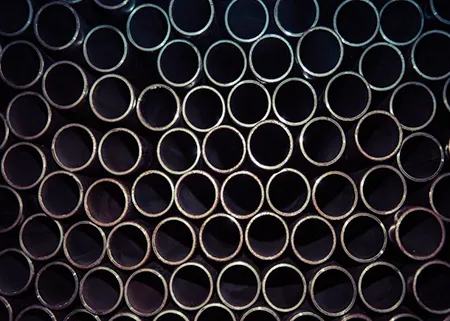

These two terms are not new. It is especially true if you often interact with plumbing or irrigation pipes. These are essential parts, especially when dealing with modern structures.

It is through plumbing that we access fresh water in our homes. Conversely, these pipes also help eliminate wastewater through drainage systems. For any such project, the most important tools needed are the pipes. They come in various shapes and materials suitable for different applications.

Schedule 20 and Schedule 40 are the most used pipes in water management projects. It’s evident that the numbers they carry are different. So, their features and applications are also very different.

In today’s blog, we will tackle these two standard pipes. Additionally, we explore their differences and ideal applications. Also, we will look at what you should check in each pipe when selecting one that suits your needs.

Image Source: Pixabay

Key Takeaways

- Schedule 20 and Schedule 40 are common pipe types. They vary in wall thickness, with Schedule 40 pipes having thick walls.

- Schedule 20 pipes are ideal for residential plumbing, irrigation systems, and low-pressure applications.

- Schedule 40 pipes are suitable for high-pressure environments and underground installations.

- You must consider different factors when choosing between these two pipes.

- At Alloyxpert, we can help you choose the most suitable pipe type.

What Is a Pipe Schedule?

When discussing pipe schedules, this is not the typical schedule you are used to. It’s deeper and very different from what you know! Well, a pipe schedule refers to the wall thickness of a pipe. Pretty simple, right?

This system ensures the pipe’s strength and longevity requirements are achieved. In short, you expect a thick wall to have a stronger pipe. Conversely, a thin wall will have a weaker but functional pipe.

The pipe schedule is usually non-dimensional. It depends on the internal pipe working pressure. The nominal pipe size and material used to determine the pipe schedule number are also used.

You check the pipe schedule number to determine how robust a pipe is. The higher the schedule number, the stronger the pipe is. It will ultimately direct you to use the pipe for your upcoming project.

Now, schedule 40 pipes will feature thicker walls than a schedule 20 pipe. Therefore, the schedule 40 pipe is stronger. This pipe is best suited for high-pressure applications. Also, it is ideal for situations that need extra durability.

On the other hand, the schedule20 pipe is lighter. It is more economical and ideal for residential low-pressure uses.

What Are the Common Types Of Pipe Schedules?

| Types | nps (inch) | OD (mm) | ID (mm) | Weight per meter (kg/m) |

| SCH5 | 1 | 25.4 | 24.1 | About 0.4007 |

| 2 | 50.8 | 49.5 | About 1.6028 | |

| 3 | 76.2 | 74.8 | About 3.6061 | |

| 4 | 101.6 | 100.1 | About 6.4096 | |

| 6 | 152.4 | 150.8 | About 14.4164 | |

| 8 | 203.2 | 201.6 | About 25.6384 | |

| SCH10 | 1 | 33.4 | 30.6 | About 1.375 |

| 2 | 60.3 | 56.5 | About 3.805 | |

| 3 | 88.9 | 84.9 | About 7.925 | |

| 4 | 114.3 | 110.5 | About 13.75 | |

| 6 | 168.3 | 162.1 | About 30.61 | |

| 8 | 219.1 | 212.7 | About 53.65 | |

| SCH20 | 1 | 33.4 | 29.8 | About 1.375 |

| 2 | 60.3 | 53.8 | About 3.805 | |

| 3 | 88.9 | 82.5 | About 7.925 | |

| 4 | 114.3 | 107.2 | About 13.75 | |

| 6 | 168.3 | 158.1 | About 30.61 | |

| 8 | 219.1 | 206.7 | About 53.65 | |

| SCH40 | 1 | 33.4 | 27.2 | About 1.375 |

| 2 | 60.3 | 50.8 | About 3.805 | |

| 3 | 88.9 | 75.5 | About 7.925 | |

| 4 | 114.3 | 102.9 | About 13.75 | |

| 6 | 168.3 | 156.7 | About 30.61 | |

| 8 | 219.1 | 202.9 | About 53.65 |

Note:

- The units of outside diameter (OD) and inside diameter (ID) are in millimeters.

- The weight per meter (kg/m) is calculated based on the outer diameter, inner diameter, wall thickness and density of carbon steel(7850 kg/m3) for each size, and the result is rounded to the appropriate accuracy.

What Are the Differences Between Schedule 20 and Schedule 40 Steel Pipes?

Image Source: Pexels

These two are the most common pipes available. While they might seem similar, they vastly differ. These differences make them best suited to their specific applications.

Pipe Diameter

One factor that sets Schedule 20 and Schedule 40 apart is their diameters. The two share the exact outer dimensions. The inner ones are, however, very different.

Schedule 20 pipe is typically broad and has a large diameter. It allows more liquid to flow through it seamlessly. On the other hand, schedule 40 has thicker inner walls that are narrower. It restricts the flow of substances due to its small inner diameter.

Typically, the schedule 20 pipes can accommodate a higher volume of fluid flow. Therefore, they are an attractive choice for applications requiring higher flow rates. It includes areas such as water distribution systems. This is unlike the Schedule 40 pipe, even with the same outer diameter.

The thinner walls of the Schedule 20 pipes may not withstand extreme stress or pressure. Assume you are blowing through a wide straw. You can move more air. However, it might not hold up well against intense pressure.

So, what should you go for? It all boils down to the application with which you are working. If your application requires a high flow rate, pressure is not much of a concern. Then, schedule 20 pipes should be the go-to choice.

If you need a pipe that can bear high pressures and stresses, then Schedule 40 might be the ideal choice.

Wall Thickness

The wall thickness between schedule 20 pipes and schedule 40 pipes is different. One is built for lighter use. The other one can withstand complex applications without wearing and tearing.

Schedule 20 pipes have pretty thin walls. That makes them suitable for extreme-pressure applications. They are lighter and more economical to produce and transport. Thus, they are ideal for extreme-pressure applications.

Schedule 40, on the other hand, has thick walls. They can effectively handle higher pressure. They are also suitable for more demanding environments without spoiling.

Weight

First, you can use this handy metal weight calculator.

The weight of Schedule 20 and Schedule 40 steel pipes differs due to their wall thickness. Schedule 20 pipes have thinner walls, making them lighter than Schedule 40.

Schedule 20 pipes have thinner walls, making them lighter than Schedule 40. This lightweight nature makes it easier to work in certain situations. Likewise, Schedule 40 pipes have thicker walls, contributing to their increased weight. This added weight is a result of their toughness.

Large-scale Industrial Installations

Durability and pressure resistance are crucial in industrial applications. Thus, the added weight of Schedule 40 pipes may not be a significant concern. The benefits of their increased strength outweigh the challenges.

Outdoor Installations

The weight of Schedule 40 pipes can be helpful when installing pipes outdoors. Its weight helps keep the pipes stable and less likely to shift or move over time.

Pressure Rating

Pressure rating is another significant difference between schedule 20 and schedule 40 pipes. The pressure rating indicates the maximum pressure a pipe can safely withstand. It is essential in many applications.

Schedule 20 pipes have a lower pressure rating compared to schedule 40 pipes. These pipes can handle little internal pressure. It is the reason why such pipes are used in minimal-stress applications. They are used in residential plumbing systems or irrigation systems.

Converse to the schedule 20 pipes, the schedule 40 pipes’ pressure is high. They are designed to handle high stress levels. These pipes are ideal for use in commercial spaces. Understanding the applications of these two stainless steel pipes is vital.

It will direct you to select the ideal pipe for the right industry. These pipes find application in diverse sectors. It spans from areas with water lines to gas pipelines and the oil and gas industries.

We have already covered a post for you – Everything You Should Know About Pipeline Pressure Rating and Ways to Calculate It!

What Are the Applications of Schedule 20 and Schedule 40 Steel Pipes?

The selection between these pipes depends on the application. You must perform proper engineering calculations to ensure the effective use of these pipes.

Applications of Schedule 20

Water is used for various critical applications. Therefore, its efficient management is crucial. Schedule 20 is helpful in water resources management in many ways.

Moreover, these pipes transport air, gasses, and other fluids in low-pressure airlines. These items are required for various aircraft systems and ground support equipment.

The following are the Applications of Schedule 20 pipes:

| Category | Application Area | Specific Use | Key Points |

| Water Resource Management | Drainage Systems | · Prevent flooding & ensure proper water flow | · Lightweight & affordable · Suitable for moderate pressure & flow · Popular in urban drainage & residential/commercial plumbing |

| Irrigation Systems | · Convey water for sprinklers & drip systems · Distribute water in nurseries & greenhouses | · Ideal for municipalities & property developers | |

| Air Transportation | Aircraft air supply systems | · Low-pressure airlines (air, gas, fluids) · Aircraft air supply systems (cabin pressurization, environmental control) | · Lightweight & durable · Ideal for moderate pressure applications |

| Industrial Applications | Chemical Piping | · Transport low-pressure chemicals, liquids, & gasses | · Suitable for water or chemicals |

| Ship Sewage Piping | · Handle wastewater & sewage on ships | · Easy to install in confined spaces | |

| Industrial Ventilation Ducting | · Remove dust & airborne contaminants | · Maintain air circulation & cleanliness |

Applications of Schedule 40

Image Source: Pixabay

Schedule 40 pipes are excellent at transmission lines thanks to their robust nature and high-pressure resilience.

Besides, these pipes can help perform underground piping work. Underground drainage systems are characterized by high pressure. Fortunately, these pipes can endure it and last long.

Schedule 40 pipes are also utilized in the oil and gas industry for various uses. One of the most common ways is as a casing. The fact that they are thick provides a lining to the wellbore. It ensures structural integrity, preventing it from collapsing.

The following are the Applications of Schedule 40 pipes:

| Application Area | Specific Use | Key Points |

| Conveying Pipelines | · Transmission lines for high-pressure applications | · Thick walls for strength · Suitable for long-distance transportation of refinery products |

| Underground Engineering | · Underground drainage systems · Rainwater and general drainage | · Withstand high pressure and weight of soil · Long-lasting due to durability |

| Oil and Gas Industry | · Wellbore casing · Piping for oil and gas transport | · Thick walls provide structural integrity · Suitable for high-pressure applications |

Cost Comparison Between Schedule 20 and Schedule 40 Steel Pipe

Now, cost is to be considered when purchasing a piping system. So, what is the cost breakdown? Take a look here!

Schedule 20 is more cost-effective than schedule 40 steel pipes. This is mainly due to their thinner wall thickness. It typically means that they require less raw materials to manufacture. So, their production costs are lower, which is a more economical option for buyers.

Other costs include pipe installation and transportation costs. These two can play a significant role in determining the overall price of the pipe.

Luckily, schedule 20 is lightweight, requiring less labor to transport and install it. So, buyers can save on costs when using this pipe rather than schedule 40 pipes.

Schedule-20 pipes may necessitate earlier replacement than schedule-40 pipes. This is because of their low-pressure rating and the fact that they do not last long. They may wear out early, requiring immediate replacement, unlike schedule-40 pipes.

What Factors Should You Consider When Choosing Between Schedule 20 and Schedule 40?

Image Source: Pexels

First, you can learn more about specific terms by studying this extensive metal library. You must know the below key factors to evaluate when choosing between these steel pipes.

Gas Pressure

Gas pressure is crucial when choosing between Schedule 20 and Schedule 40 pipes.

Schedule 20 pipes are suitable for transporting gases at lower pressures. They are used in applications like low-pressure gas distribution lines and ventilation systems. However, their thinner walls limit their ability to handle high-pressure gas applications.

Likewise, Schedule 40 pipes are designed to handle medium to high gas pressures. They are typically used in industrial settings where more robust pipes are needed. Their thicker walls provide increased pressure resistance. These pipes are used in oil and gas processing plants, refineries, or gas transmission lines.

Also Read: How to Calculate the Pressure Rating of Stainless Steel Pipes?

System Requirements

Extreme temperatures and frequent pressure variations can impact the pipe’s performance. Additionally, it determines how long pipes last.

The thick walls in schedule 40 pipes enable them to handle these demanding conditions. The dense materials provide better resistance to thermal expansion and contraction. They are also able to tolerate pressure surges to a large extent.

Schedule 20 pipes may not withstand the extreme temperatures and pressure fluctuations. They have thin walls. It makes them susceptible to deformation or failure when put in extreme conditions.

Does your system experience significant temperature swings or pressure spikes? Investing in Schedule 40 pipe might be the best decision. It is due to their added strength and ability to stand the test of time.

Also Read: High-Temperature Pipeline Solutions: The Role of Stainless Steel

Design Drawings and Industry Standards

Design drawings and industry standards are crucial factors when installing a piping system.

These drawings provide a detailed blueprint of the piping system. It often specifies the layout, dimensions, and materials to be used.

Industry standards provide guidelines and best practices for piping system design and installation. Organizations like ASME and API often establish these standards. They outline minimum requirements for wall thickness, pressure ratings, and material specifications.

FAQs

What Does Schedule 40 Pipe Thickness Mean?

Schedule 40 pipe thickness means the standardized wall thickness of a pipe. The higher the schedule number, the thicker the pipe wall.

How Thick Is a 6-inch Schedule 40 Pipe?

A 6-inch schedule 40 pipe has a wall thickness of 0.280 inches, approximately 7.11 mm. The pipe wall thickness is measured from the inside of the pipe to the outside. The wall thickness and diameter dimensions are often standardized to ensure compatibility.

How Heavy Is a 6-inch Schedule 40 Pipe?

A 6-inch schedule 40 pipe weighs approximately 18.97 pounds per foot, i.e., 28.26 kg/m. This weight can change depending on the material of the pipe.

How Thick Are Schedule 40 Fittings?

The thickness of schedule 40 fittings varies. It often depends on the fitting type and size. Generally, these fittings have a wall thickness similar to that of the schedule 40 pipes.

Final Thoughts!

Ready to make your purchase? Schedule 20 and Schedule 40 steel pipes are essential in many industries. Their differences are apparent, and they all serve unique purposes.

Understand each of the pipes and how well they function before purchasing. We hope this guide has given you what you need to know when dealing with Schedule 20 and Schedule 40 pipes.

Consider the pressure requirements when choosing between Schedule 20 and Schedule 40 pipes. The difference between these two pipe schedules is the pressure they can withstand. Schedule 40 pipes have thick walls. Besides, they are designed to handle high pressure compared to Schedule 20 pipes.

However, we always recommend taking expert advice, especially for critical projects. At Alloyxpert, our team has extensive experience in various steel pipe schedules. We can provide tailored guidance to ensure you choose the most suitable pipe type. So, get in touch now!

Read More:

Schedule 40 Steel Pipe – How to Choose the Best One?

Why Schedule 80 Steel Pipe is Best for High-Pressure Systems?

Comprehensive Guide to Schedule 10 Steel Pipe: Dimensions, Thickness, and Applications